Nitrogen-containing aluminum silicate compound red luminescent material and preparation method thereof

A silicon compound, red light-emitting technology, applied in the fields of light-emitting materials, chemical instruments and methods, sustainable buildings, etc., can solve the problems of poor thermal stability, easy deliquescence, low luminous efficiency, etc., achieve complete crystallization, reduce raw material costs, light The effect of high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

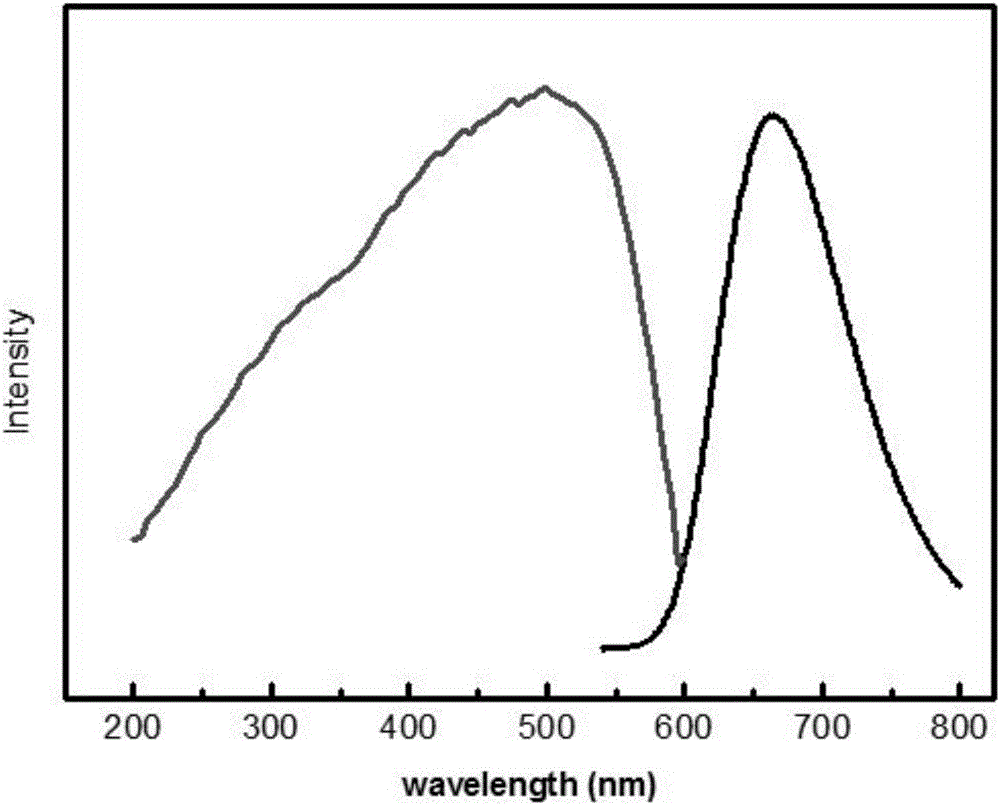

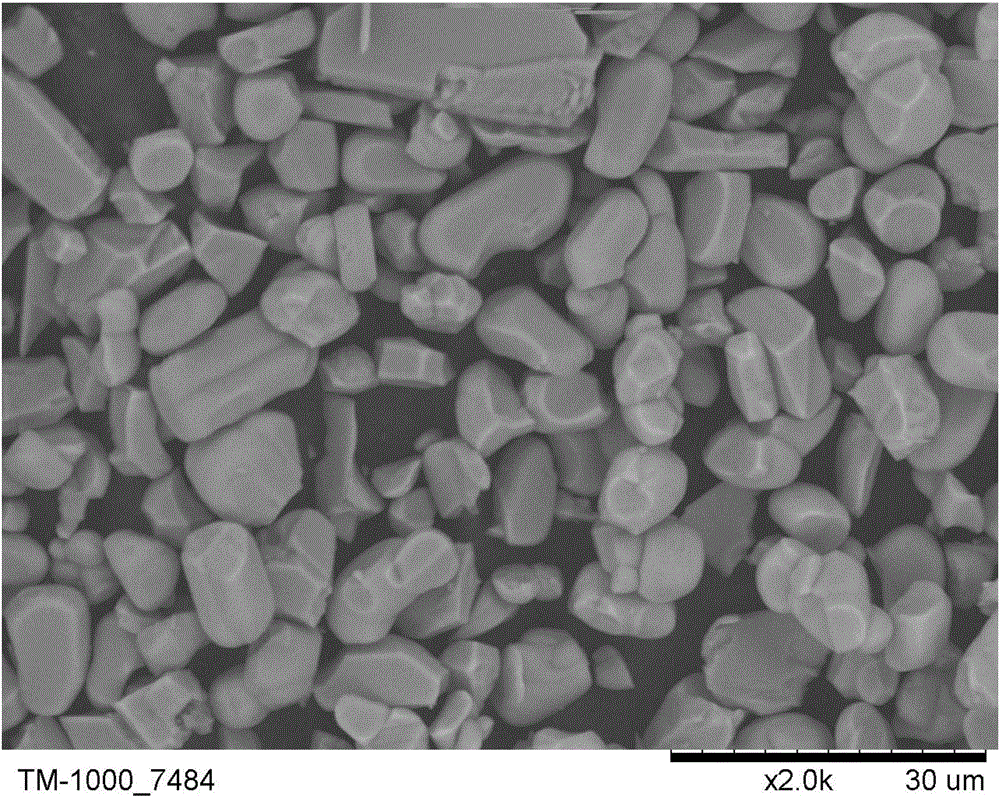

[0030] Example 1: Sr 2.995 AlSi 6 N 11 :0.005Eu 2+ Preparation example of luminescent material

[0031] In order to obtain the composition formula Sr 2.995 AlSi 6 N 11 :0.005Eu 2+ For the compound luminescent material represented, weigh Sr(NO 3 ) 2 , Al(NO 3 ) 3 , Eu(NO 3 ) 3 , nano-silicon solution, 0.5% NH with solid raw material mass fraction 4 Cl was used as a flux, and the above raw materials were dissolved in pure water under ultrasonic stirring, and stirred for 1 h. After mixing evenly, it was introduced into a spray pyrolysis device for spray drying. The spray drying conditions were: high-purity nitrogen was used as the carrier gas, and the nitrogen pressure was 6.5×10 5 KPa, the gas flow rate is 700L h -1 , the inlet temperature is 230°C, the outlet temperature is 130°C, and the spray speed is 80mL·h -1 The nano-precursor particles of the obtained nitrogen-containing aluminum-silicon compound red luminescent material are collected with a filter bag und...

Embodiment 2

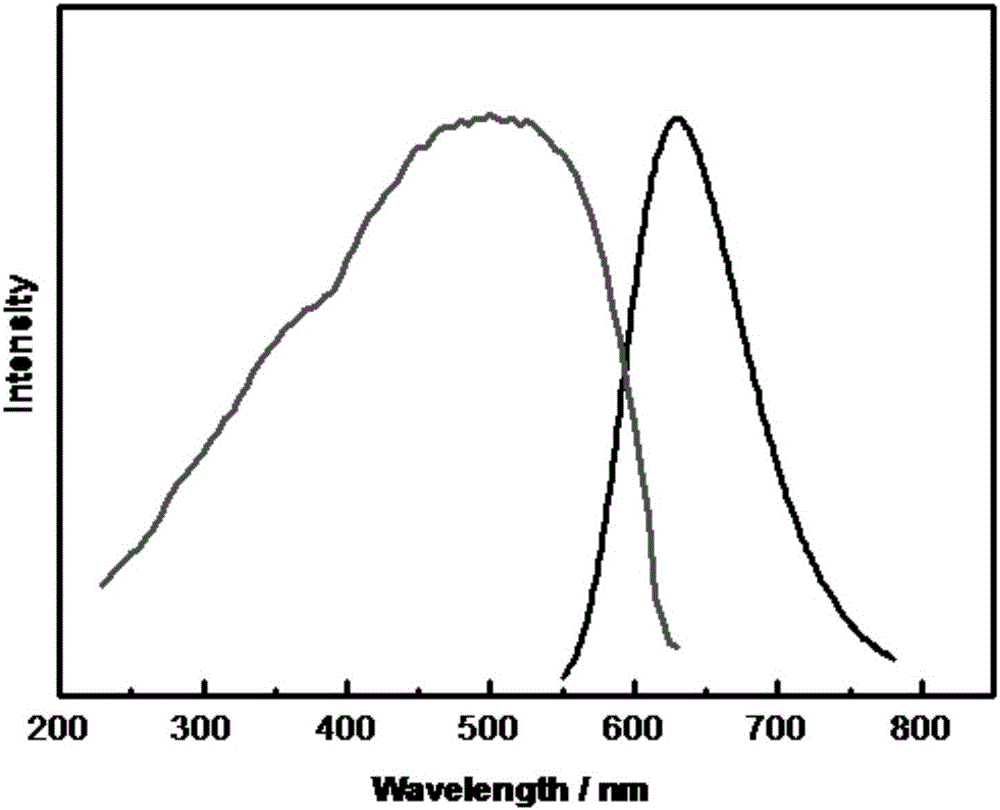

[0033] Example 2: Ca 2.99 AlSi 6 N 11 :0.01Eu 2+ Preparation example of luminescent material

[0034] In order to obtain the composition formula Ca 2.99 AlSi 6 N 11 :0.01Eu 2+ For the compound luminescent material represented, weigh Ca(NO 3 ) 2 , Al(NO 3 ) 3 , Eu(NO 3 ) 3 , nano-silicon solution, 0.5% NH with solid raw material mass fraction 4 Cl was used as a flux, and the above raw materials were dissolved in pure water under ultrasonic stirring, and stirred for 1 h. After mixing evenly, it was introduced into a spray pyrolysis device for spray drying. The spray drying conditions were: high-purity nitrogen was used as the carrier gas, and the nitrogen pressure was 6×10 5 KPa, the gas flow rate is 650L h -1 , the inlet temperature is 225°C, the outlet temperature is 120°C, and the spray speed is 80mL·h -1 The nano-precursor particles of the obtained nitrogen-containing aluminum-silicon compound red luminescent material are collected with a filter bag under nit...

Embodiment 3

[0036] Example 3: Sr 2.99 Ba 0.005 AlSi 6 N 11 :0.005Eu 2+ Preparation example of luminescent material

[0037] In order to obtain the composition formula Sr 2.99 Ba 0.005 AlSi 6 N 11 :0.005Eu 2+ Represented compound, weigh Sr(NO 3 ) 2 , Ba(NO 3 ) 2 , Al(NO 3 ) 3 , Eu(NO 3 ) 3 , nano silicon solution, with 0.5% NH 4 Cl was used as a flux, and the above raw materials were dissolved in pure water under ultrasonic stirring, and stirred for 1 h. After mixing evenly, it was introduced into a spray pyrolysis device for spray drying. The spray drying conditions were: high-purity nitrogen was used as the carrier gas, and the nitrogen pressure was 7×10 5 KPa, the gas flow rate is 700L h -1 , the inlet temperature is 230°C, the outlet temperature is 130°C, and the spray speed is 80mL·h -1 The nano-precursor particles of the obtained nitrogen-containing aluminum-silicon compound red luminescent material are collected with a filter bag under nitrogen protection, and ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com