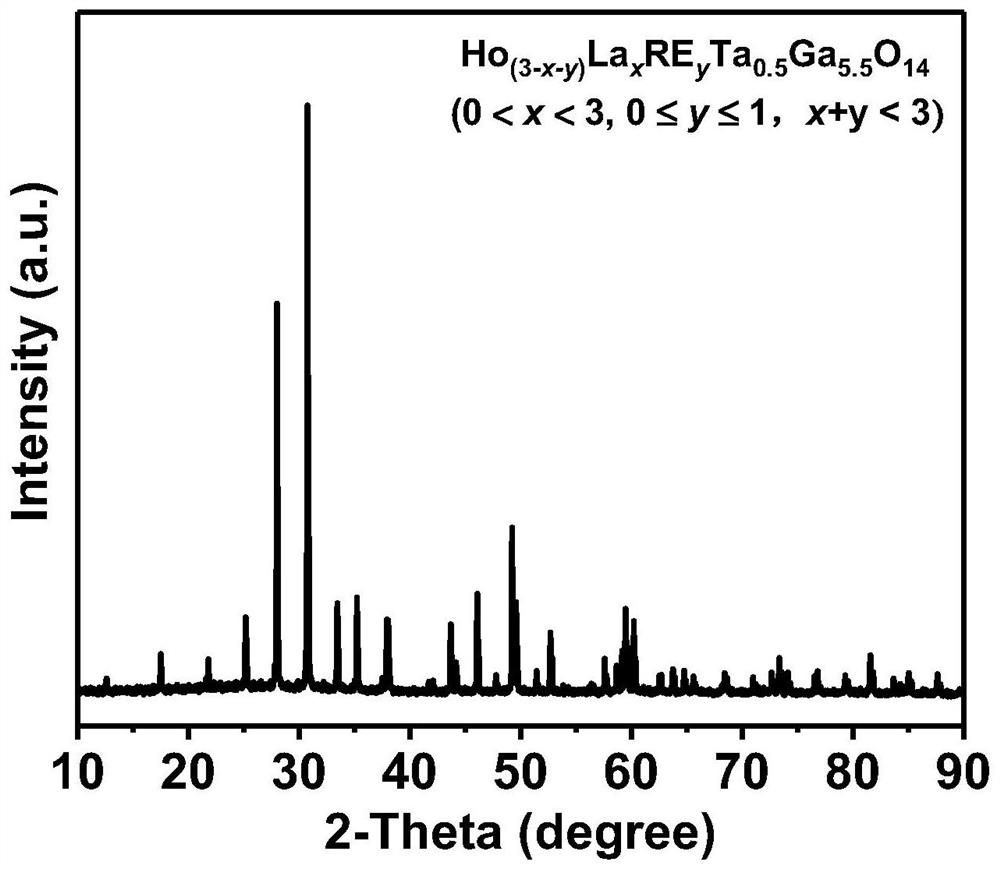

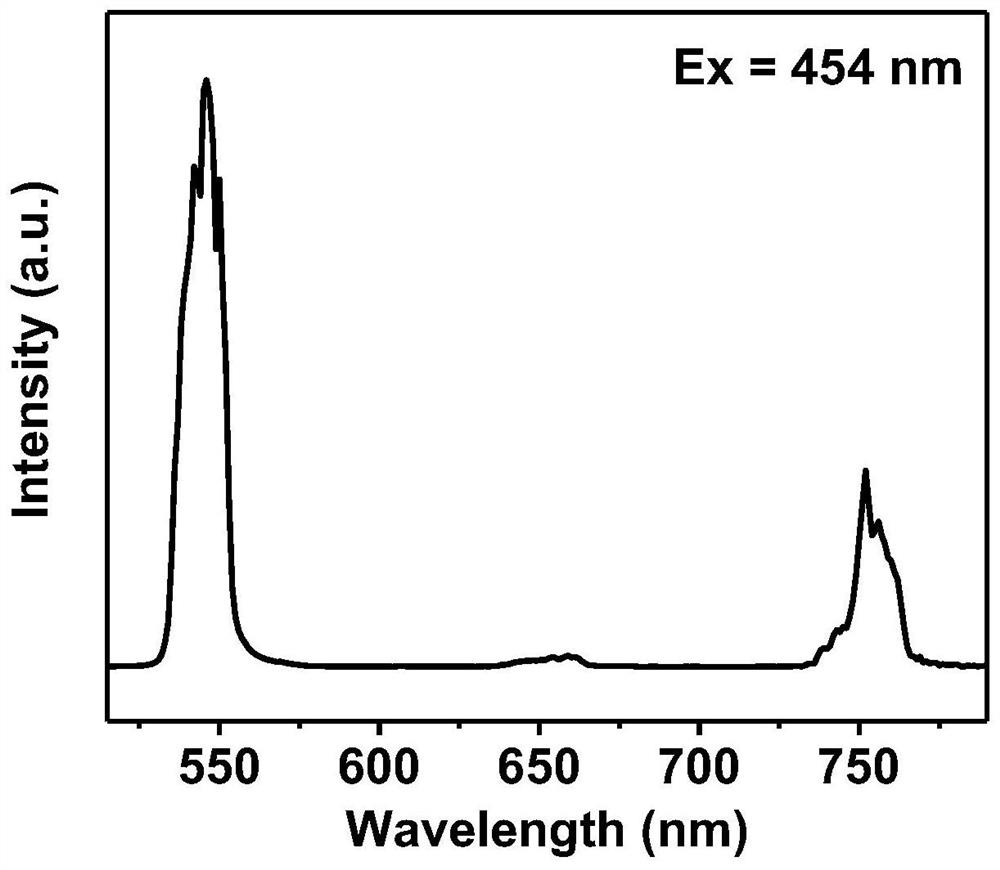

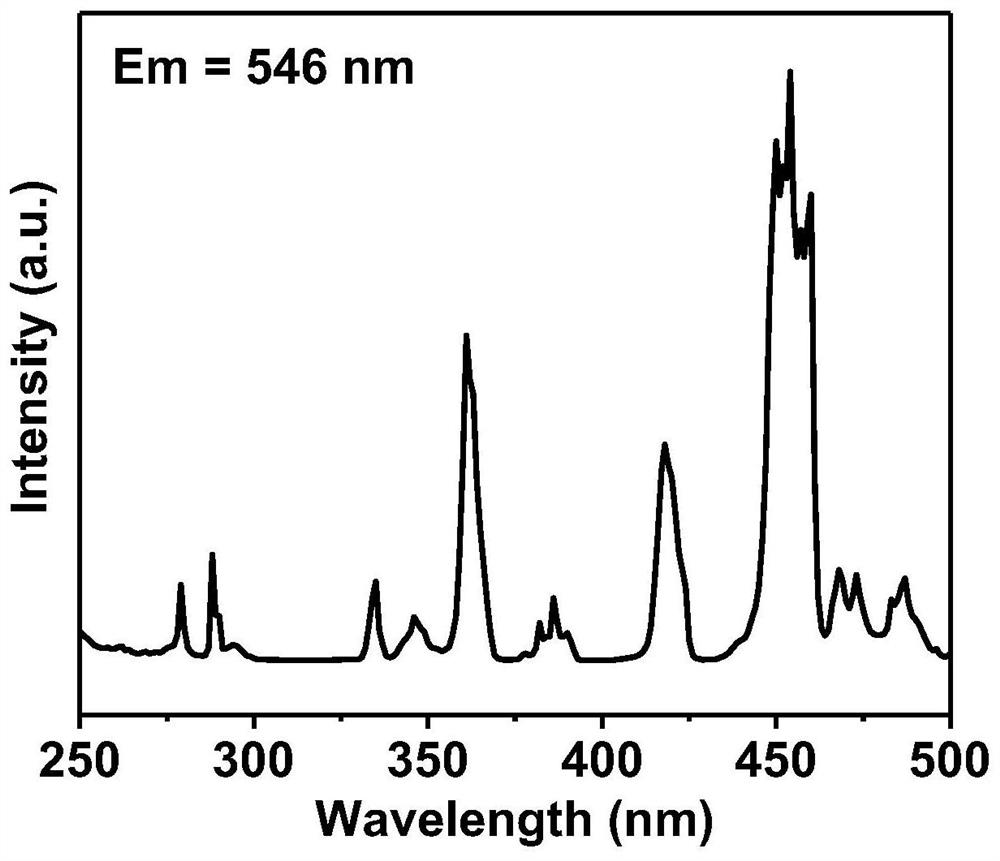

a ho 3+ Activated green down-conversion phosphor and preparation method thereof

A fluorescent powder and green technology, applied in the field of green down-conversion phosphor and its preparation, can solve the problems of reduction, inability to emit green light, complex synthesis conditions of phosphor, etc., and achieve high quantum efficiency and high luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The raw materials were weighed according to the element molar ratio Ho:La:Ta:Ga=0.045:2.955:0.5:5.5, and the said raw materials were respectively holmium oxide, lanthanum oxide, tantalum oxide, and gallium oxide. Add the raw materials into an agate mortar, grind them evenly, and transfer them into a corundum crucible, then place the corundum crucible in a high-temperature furnace, and perform the first step of pre-firing at 400°C with a heating rate of 10°C / min and a holding time of 4h. After natural cooling to room temperature, take it out for grinding, and then carry out the second step of sintering at 1400°C, the heating rate is 5°C / min, and the holding time is 4h. After the end, wait for it to cool down to room temperature naturally, and grind it evenly to get the product.

Embodiment 2

[0030] The raw materials were weighed according to the element molar ratio Ho:La:Ta:Ga=0.03:2.97:0.5:5.5, and the said raw materials were respectively holmium oxide, lanthanum oxide, tantalum oxide, and gallium oxide. Add the raw materials into an agate mortar, grind them evenly, and transfer them into a corundum crucible, then place the corundum crucible in a high-temperature furnace, and perform the first step of pre-firing at 300°C, with a heating rate of 5°C / min and a holding time of 3h. After natural cooling to room temperature, take it out for grinding, and then carry out the second step of sintering at 1000°C, the heating rate is 10°C / min, and the holding time is 6h. After the end, wait for it to cool down to room temperature naturally, and grind it evenly to get the product.

Embodiment 3

[0032] The raw materials were weighed according to the element molar ratio Ho:La:Ta:Ga=0.15:2.85:0.5:5.5, and the said raw materials were respectively holmium oxide, lanthanum oxide, tantalum oxide and gallium oxide. Add the raw materials into an agate mortar, grind them evenly, and transfer them into a corundum crucible, then place the corundum crucible in a high-temperature furnace, and perform the first step of pre-firing at 600°C with a heating rate of 10°C / min and a holding time of 2h. After natural cooling to room temperature, take it out for grinding, and then carry out the second step of sintering at 1400°C, the heating rate is 10°C / min, and the holding time is 6h. After the end, wait for it to cool down to room temperature naturally, and grind it evenly to get the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com