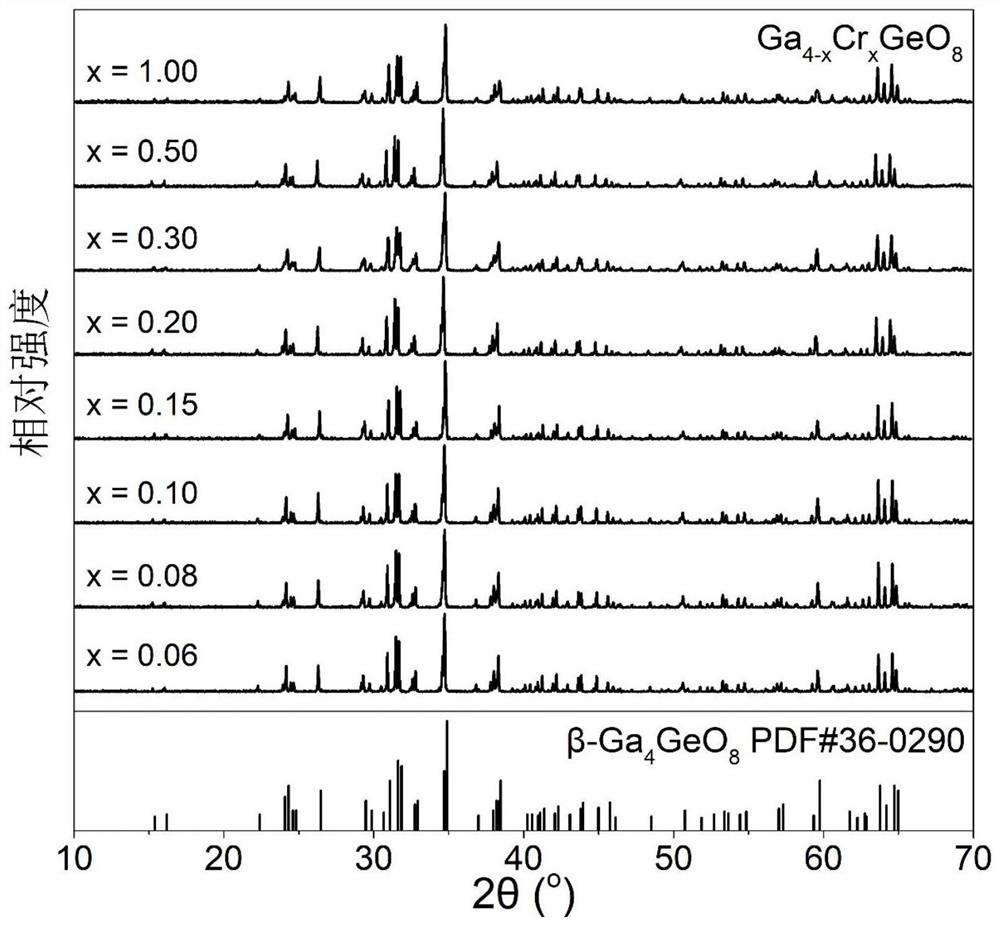

Infrared fluorescent powder for LED (light-emitting diode), preparation method thereof and infrared light-emitting device

A technology of infrared luminescence and fluorescent powder, which is applied in the direction of luminescent materials, chemical instruments and methods, semiconductor devices, etc., can solve the problems of low infrared emission efficiency and failure to meet application requirements, and achieve wide excitation range, thermal stability and adjustable luminescence , the effect of wide coverage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The preparation method of this embodiment is simple, easy to operate, low in cost, and pollution-free, and is suitable for industrialized batch production.

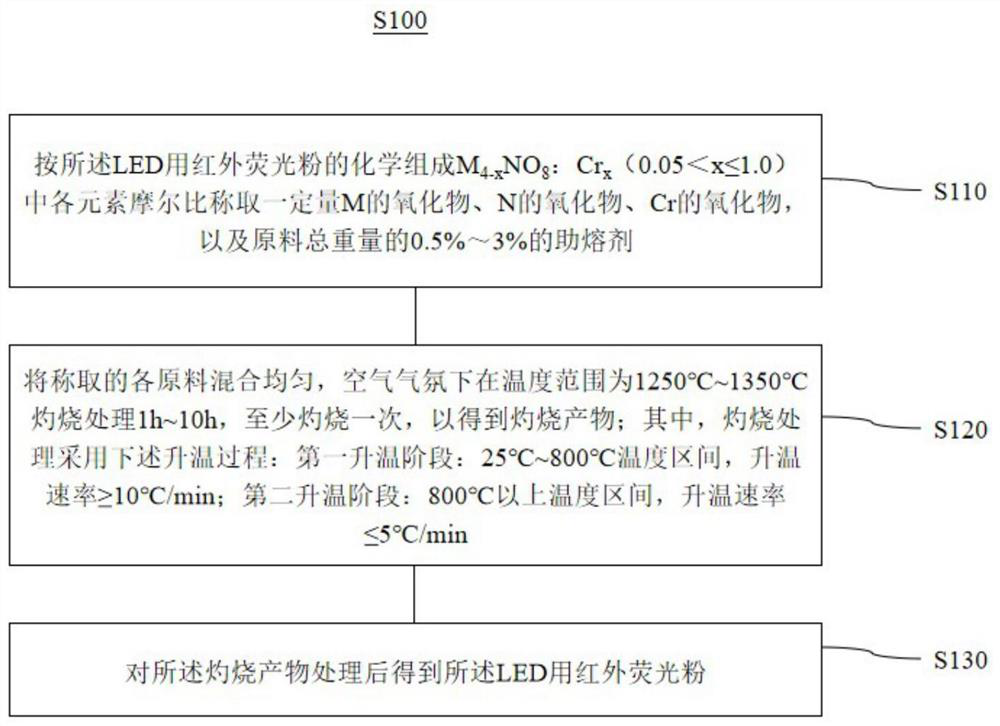

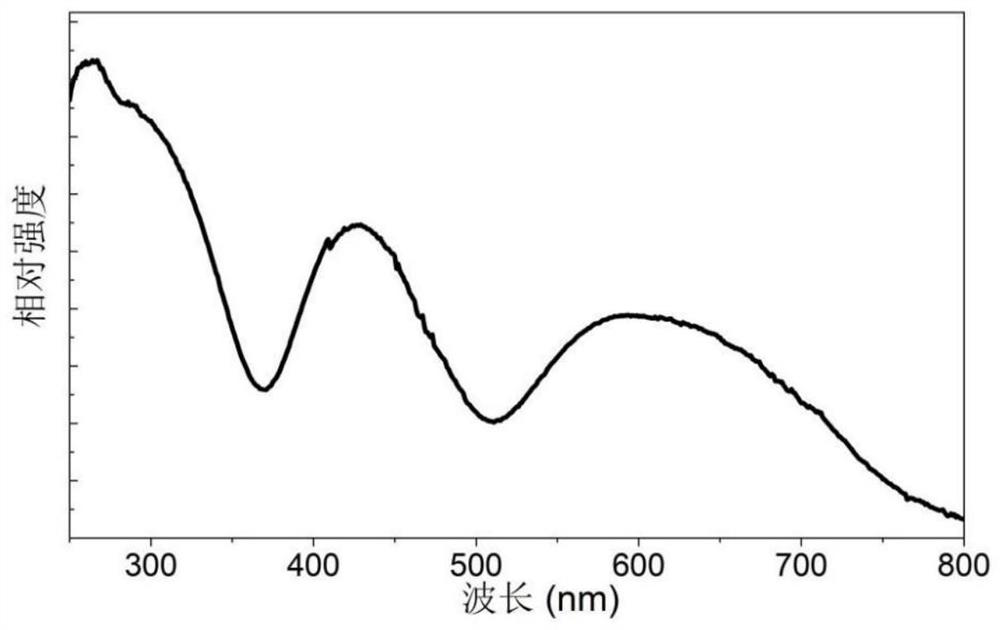

[0057] Another aspect of the present invention provides an infrared light-emitting device comprising an excitation source and an infrared fluorescent material, the infrared fluorescent material using the aforementioned infrared fluorescent powder for LEDs, wherein the emission peak wavelength range of the excitation source is 250nm-780nm.

[0058] Specifically, in some embodiments, the emission peak wavelength range of the above excitation source may also preferably be 250 nm-380 nm, 400 nm-500 nm, or 530 nm-780 nm.

[0059] It should be noted that this embodiment does not specifically limit the excitation source, for example, an LED chip may be used.

[0060] Further, this embodiment also provides a preparation method of the infrared light-emitting device, including the following steps:

[0061] First, fully mixi...

Embodiment 1

[0066] In this example, the preparation method of infrared phosphor for LED, the chemical expression of the phosphor is Ga 3.949 Cr 0.051 GeO 8 , the preparation method comprises the following steps:

[0067] S1. According to the stoichiometric ratio between the elements of the above chemical formula, accurately weigh the raw material Ga 2 O 3 1.9745mol, Cr 2 O 3 0.0255mol, GeO 2 1mol.

[0068] S2, the above-mentioned each raw material and the boric acid of the raw material weight 0.5% taken by weighing are used as fluxing agent, after fully mixing, the crucible is put into the electric furnace, and sintered in air atmosphere, wherein, the heating process is set as follows: the first heating stage : 25°C~800°C temperature range, heating rate 10°C / min; second heating stage: temperature range above 800°C, heating rate 5°C / min. When the temperature reaches 1250 ℃, it is fired for 10 hours, and then cooled to room temperature with the furnace to obtain the fired product. ...

Embodiment 2

[0072] In this example, the preparation method of infrared phosphor for LED, the chemical expression of the phosphor is Ga 3.94 Cr 0.06 GeO 8 , the preparation method comprises the following steps:

[0073] S1. According to the stoichiometric ratio between the elements of the above chemical formula, accurately weigh the raw material Ga 2 O 3 1.97mol, Cr 2 O 3 0.03mol, GeO 2 1mol.

[0074] S2, the above-mentioned each raw material taken and the boric acid of the raw material weight 3% are used as fluxing agent, after fully mixing, the crucible is put into the electric furnace, and sintered in air atmosphere, wherein, the heating process is set as follows: the first heating stage : 25 ℃~800 ℃ temperature range, heating rate 12 ℃ / min; second heating stage: temperature range above 800 ℃, heating rate 4 ℃ / min. When the temperature reaches 1350 ℃, it is fired for 1 hour, and then cooled to room temperature with the furnace to obtain the fired product.

[0075] S3, the obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com