A kind of phosphate-based phosphor material and its preparation method and application

A phosphor and phosphate technology, applied in luminescent materials, chemical instruments and methods, semiconductor devices, etc., can solve the problems of less research on phosphor materials, no corresponding fields, mature products, etc., and achieve good luminescence thermal stability. , wide spectrum, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A phosphate-based phosphor material, the chemical expression of the phosphor is LiAl 0.99 P 2 o 7 : 0.01Cr, its preparation steps are as follows:

[0032] 1. Accurately weigh raw material Li 2 CO 3 0.5mmol, Al 2 o 3 0.495mmol, NH 4 h 2 PO 4 2mmol, Cr 2 o 3 0.005mmol;

[0033] 2. Fully mix the weighed raw materials, burn in the air at 800°C for 6 hours, and cool to room temperature with the furnace to obtain the burnt product;

[0034] 3. Fully grind the obtained calcined product into powder and pass through a 200-mesh sieve, wash once with deionized water, and dry at 60°C to obtain the LiAl of the present invention 0.97 P 2 o 7 : 0.01Cr phosphate-based phosphor material.

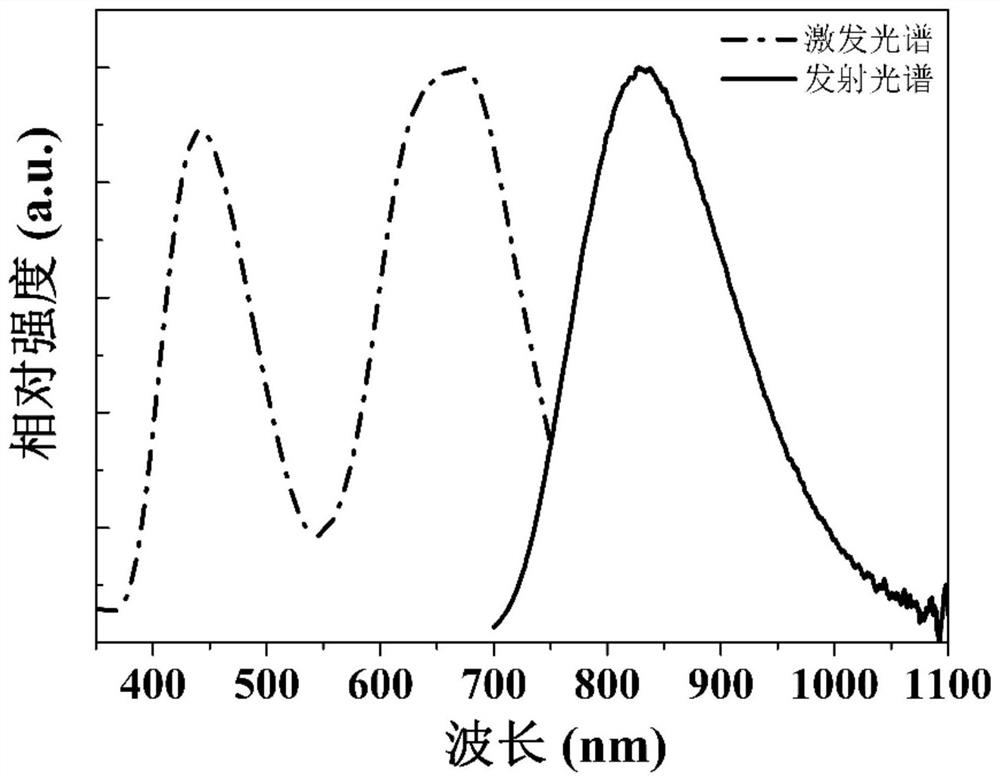

[0035] The excitation spectrum and emission spectrum of this embodiment are as attached figure 1 It can be seen from the figure that the phosphor material in this embodiment can be excited by visible light in the range of 400-520nm and 550-780nm, and emit broadband near-infrared lig...

Embodiment 2

[0037] A phosphate-based phosphor material whose chemical expression is NaGa 0.98 P 2 o 7 : 0.02Cr, its preparation steps are as follows:

[0038] 1. Accurately weigh the raw material Na 2 CO 3 0.5mmol, Ga 2 o 3 0.49mmol, NH 4 h 2 PO 4 2mmol, Cr 2 o 3 0.01mmol;

[0039] 2. Fully mix the weighed raw materials, burn in the air at 900°C for 8 hours, and cool to room temperature with the furnace to obtain the burnt product;

[0040]3. Fully grind the roasted product into powder and pass through a 200-mesh sieve, wash twice with deionized water, and dry at 80°C to obtain the NaGa powder of the present invention. 0.97 P 2 o 7 : 0.02Cr phosphate-based phosphor material.

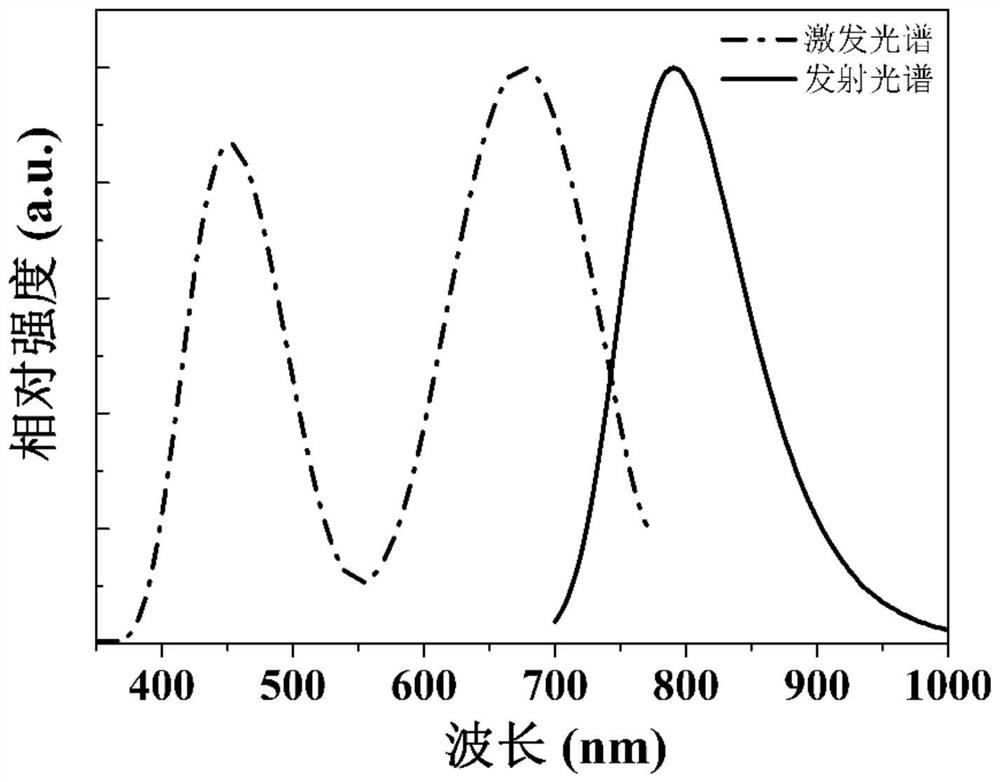

[0041] The excitation spectrum and emission spectrum of this embodiment are as attached figure 2 It can be seen from the figure that the phosphor material in this embodiment can be excited by visible light in the range of 400-520nm and 550-780nm, and emit broadband near-infrared light in the rang...

Embodiment 3

[0043] A phosphate-based phosphor material whose chemical expression is KIn 0.97 P 2 o 7 : 0.03Cr, its preparation steps are as follows:

[0044] 1. Accurately weigh raw material K 2 CO 3 0.5mmol, In 2 o 3 0.485mmol, NH 4 h 2 PO 4 2mmol, Cr 2 o 3 0.015mmol;

[0045] 2. Fully mix the weighed raw materials, burn in the air at 1100°C for 10 hours, and cool to room temperature with the furnace to obtain the burnt product;

[0046] 3. Fully grind the roasted product into powder and pass through a 200-mesh sieve, wash with deionized water for 3 times, and dry at 80°C to obtain the KIn 0.97 P 2 o 7 : 0.03Cr phosphate-based phosphor material.

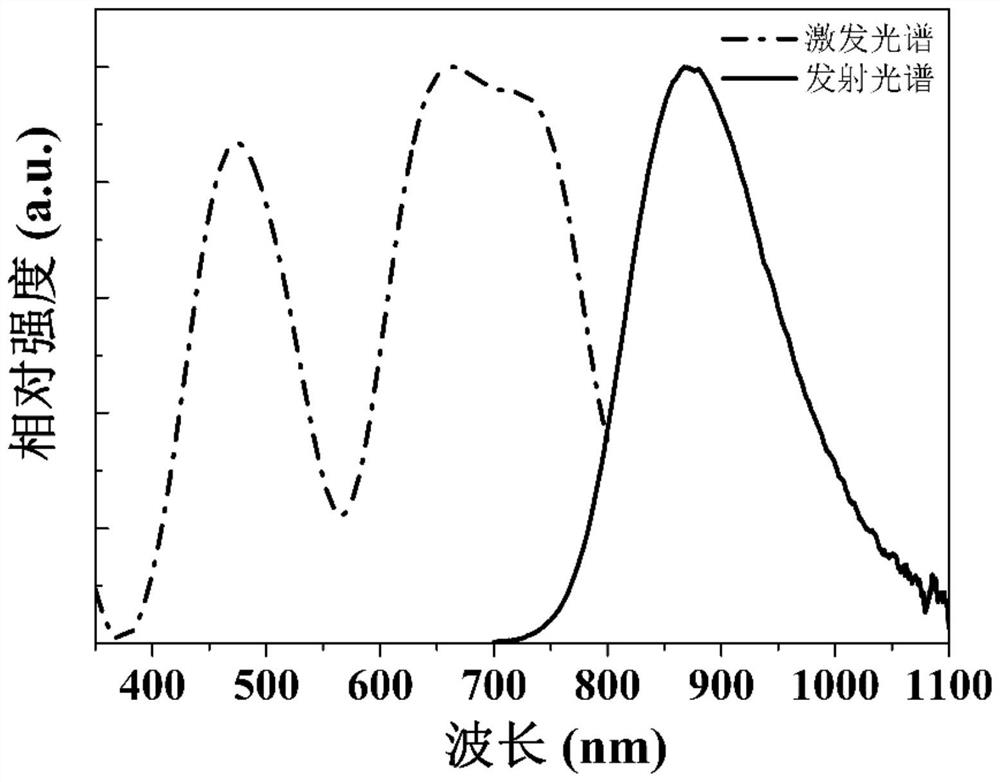

[0047] The excitation spectrum and emission spectrum of this embodiment are as attached image 3 It can be seen from the figure that the phosphor material in this embodiment can be excited by visible light in the range of 400-520nm and 550-800nm, and emit broadband near-infrared light in the range of 750-1050nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com