A preparation method and system for biomass shaped pellet fuel

A technology of pellet fuel and briquette fuel, which is applied in the field of preparation of biomass briquette pellet fuel, can solve the limitation of the physical and chemical properties of biomass molding raw materials due to seasonal changes in raw material physical and chemical properties, the development of biomass molding industry, the temperature and pressure of biomass molding, and the The problem of short life of wearing parts, etc., can alleviate the shortage of biomass raw materials, reduce the loss of molding equipment, and achieve the effect of waterproof and water absorption resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

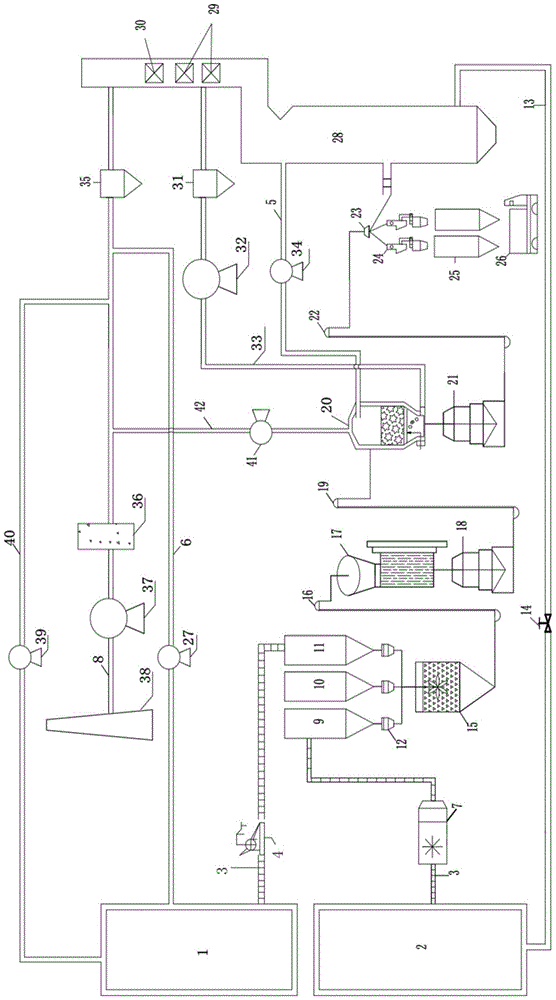

[0042] figure 1 An embodiment of the preparation system of biomass shaped granular fuel of the present invention is shown, and the preparation system includes a raw material processing system, a shaping system, a roasting system, a boiler system and a distribution system.

[0043] The raw material treatment system includes a biomass raw material treatment system and a sludge raw material treatment system. The biomass raw material treatment system includes a biomass drying device 1, a biomass crushing device 4 and a biomass bin 11 connected in sequence. 3 connection to transport biomass raw materials. The sludge raw material treatment system includes a sludge drying device 2, a sludge crushing device 7 and a sludge silo 9 connected in sequence, and the sludge raw materials are transported through the auger 3 between adjacent processes.

[0044] The forming system comprises a sludge additive silo 10, a mixing device 15, a first lifter 16, a pellet molding machine 17 and a first...

Embodiment 2

[0059] This embodiment adopts the same preparation system as in Example 1. In the preparation method of this embodiment, the biomass raw material is camphor wood chips, and the sludge raw material is papermaking sludge, which specifically includes the following steps:

[0060] 1) Drying: send the biomass raw material (camphorwood sawdust) and the sludge raw material (papermaking sludge) into the biomass drying device 1 and the sludge drying device 2 respectively, and use the temperature generated by the biomass boiler 28 at 120°C to 180°C The medium-temperature flue gas will dry the camphor wood chips to a moisture content of 13%; use the high-temperature steam of 160°C to 200°C generated by the biomass boiler 28 to dry the papermaking sludge to a moisture content of 13%, and the dried camphor wood chips will pass through The auger 3 is sent to the biomass pulverizing device 4, and the dried papermaking sludge is sent to the sludge pulverizing device 7 through the auger 3.

[...

Embodiment 3

[0067] This example uses the same preparation system as Example 1. In the preparation method of this example, the biomass raw material is corn stalks, and the sludge raw material is printing and dyeing sludge, which specifically includes the following steps:

[0068] 1) Drying: Send the biomass raw material (corn stalk) and sludge raw material (printing and dyeing sludge) into the biomass drying device 1 and the sludge drying device 2 respectively, and use the biomass boiler 28 to generate 120 ° C ~ 180 ° C The medium-temperature flue gas dries the corn stalks to a moisture content of 18%; uses the high-temperature steam of 160°C to 200°C generated by the biomass boiler 28 to dry the printing and dyeing sludge to a moisture content of 18%, and the dried corn stalks pass through the auger 3 Sent to the biomass crushing device 4, and the dried printing and dyeing sludge is sent to the sludge crushing device 7 through the auger 3.

[0069] 2) Pulverization: the dried corn stalks ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com