Feeder for straw anaerobic fermentation gas making

A feeding device and anaerobic fermentation technology, which is applied to special-purpose bioreactors/fermenters, biochemical cleaning devices, enzymology/microbiology devices, etc., can solve blockages, affect enterprise production efficiency, and reduce straw fermentation Hydrogen production and other issues, to achieve the effect of reducing material clogging, considerable economic and environmental benefits, and increasing driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

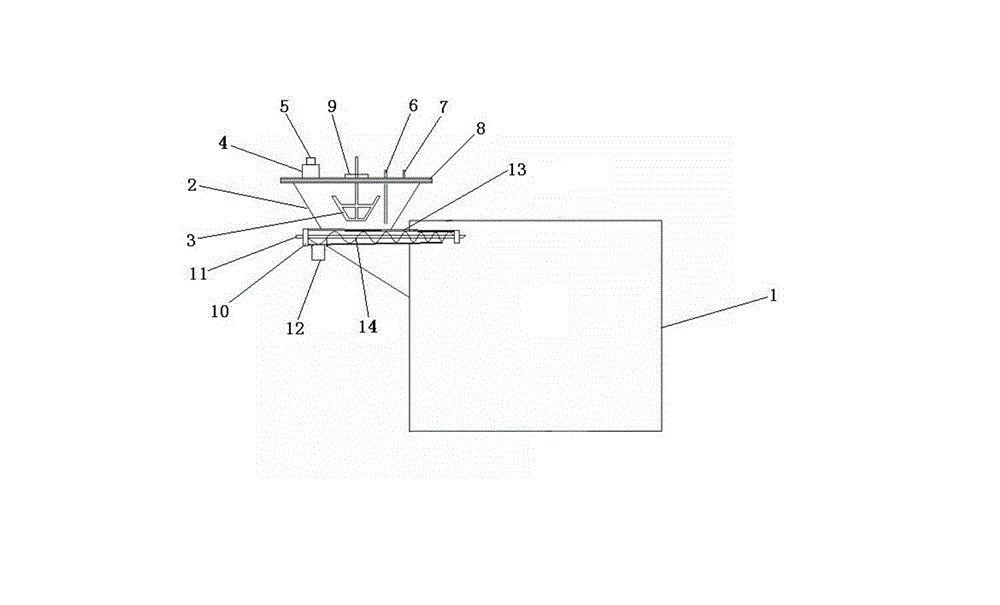

[0012] Example 1, such as figure 1 As shown, a feeding device for gas production by anaerobic fermentation of straw, the feeding device is arranged on the upper part of the reactor main body 1, the feeding device includes a feed inlet buffer 2, and the middle part of the feed inlet buffer 2 is provided with Stirrer 3, one side of the stirrer 3 is provided with a feed port 4, a butterfly valve 5 is provided at the feed port 4, and the other side of the stirrer 3 is provided with an air inlet pipe 6 and an air outlet pipe 7, wherein the air inlet pipe 6 leads into the The bottom of the material inlet buffer 2 and the top of the material inlet buffer 2 are provided with a sealing cover 8, a sealing ring 9 is provided between the sealing cover 8 and the agitator 3, and a horizontal screw propeller 10 is provided at the bottom of the material inlet buffer 2, The horizontal screw propeller 10 directly below the agitator 3 is provided with a discharge port, the discharge end of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com