Enlarged Head Capsule Anchor and Its Construction Method

A construction method and head-enlarging technology, which is applied in the direction of foundation structure engineering, buildings, sheet pile walls, etc., can solve the problems of small pull-out resistance, large investment, and inability to effectively meet the needs of engineering construction, and achieve the effect of increasing the ultimate load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

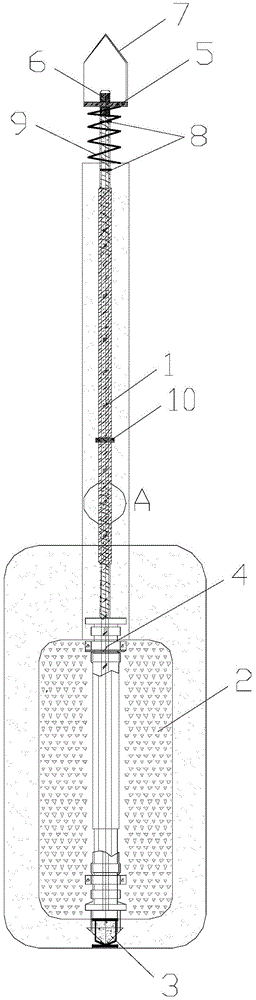

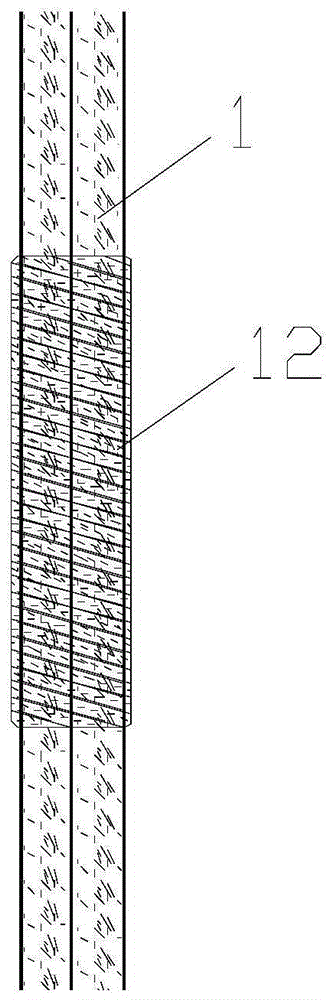

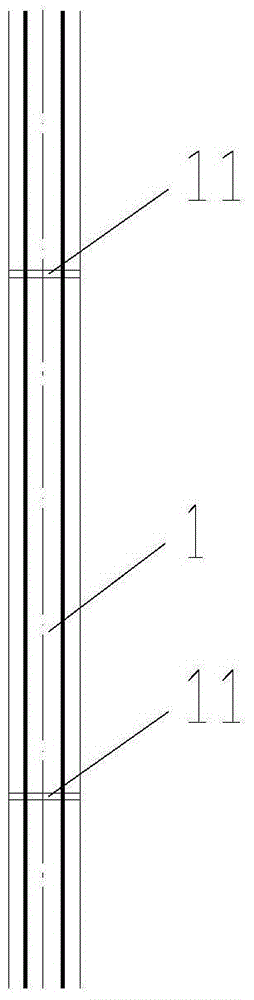

[0037] The present invention relates to an expanded-head capsule anchor rod, which includes a finished rolled threaded steel bar 1, a capsule expansion extruded body 2, and a sleeve 12. The finished rolled threaded steel bar 1 extends into the capsule type expanded extruded body 2, and The bottom of the expansion expansion body 2 is provided with a grouting material bottom cover 3, which is provided with a grout stopper 4 at the entrance of the expansion expansion body 2, and a backing plate 5 is fixed on the upper part of the finished rolled threaded steel bar 1. The threaded steel bar 1 is set with a prestressed nut 6 and the prestressed nut 6 compresses the top surface of the backing plate 5, the top surface of the backing plate 5 is fixed with a conical iron cap 7 with a reserved hole, and the conical iron cap 7 covers the set with a prestressed The finish-rolled threaded steel bar 1 of the stress nut 6, the casing 12 is set on the finished-rolled threaded steel bar 1 and h...

Embodiment example 2

[0041] 1) Drilling and forming holes

[0042]Start the high-pressure mud pump to supply high-pressure water or cement slurry or bentonite mud to the rotary jet drilling rig, and check the jetting situation of the drill bit. When the drill bit sprays stably and the drill pipe rotates smoothly, spin down to drill the hole to the design depth. When the drill reaches the design depth, stop drilling down, but keep the drill pipe rotation and high-pressure water jetting.

[0043] ①Before construction, on-site process test adjustment and determination of appropriate process parameters should be carried out, and the diameter of the expansion head and the pull-out force of the anchor should be inspected. The hole spacing error in the horizontal and vertical directions should not be greater than 100mm; the diameter of the drill bit should not be less than the design drilling diameter of 3mm; the deviation of the drilling angle should not be greater than 2 degrees; the depth of the drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com