Polycrystalline diamond composite sheet and treatment method thereof

A technology of polycrystalline diamond and composite sheet, which is applied in earth drilling, metal processing equipment, turning equipment, etc. It can solve problems such as difficult leaching, low efficiency, and unsuitability for large-scale operations, and achieves improved stability and removal Large depth and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

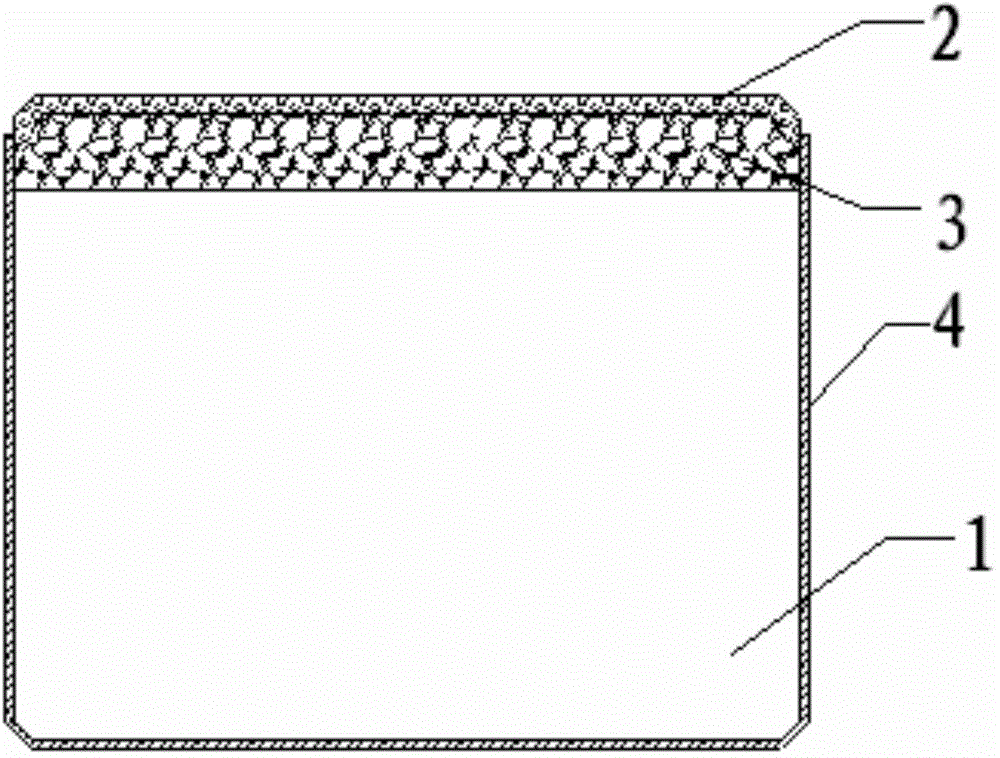

[0058] (1) Take the 1913 polycrystalline diamond composite sheet produced by Henan Jingrui Superhard Material Co., Ltd., first use acetone to clean it for 40 minutes, remove the oil on the surface of the polycrystalline diamond composite sheet, and then sandblast the cleaned polycrystalline diamond composite sheet Treat for 35s, and then conduct electrospray plating under the condition of 6m / s for 90s to obtain a polycrystalline diamond composite sheet with a polytetrafluoroethylene layer; The bottom surface and all side surfaces of the substrate and some side surfaces of the polycrystalline diamond layer, the thickness of the polytetrafluoroethylene layer is 0.5mm.

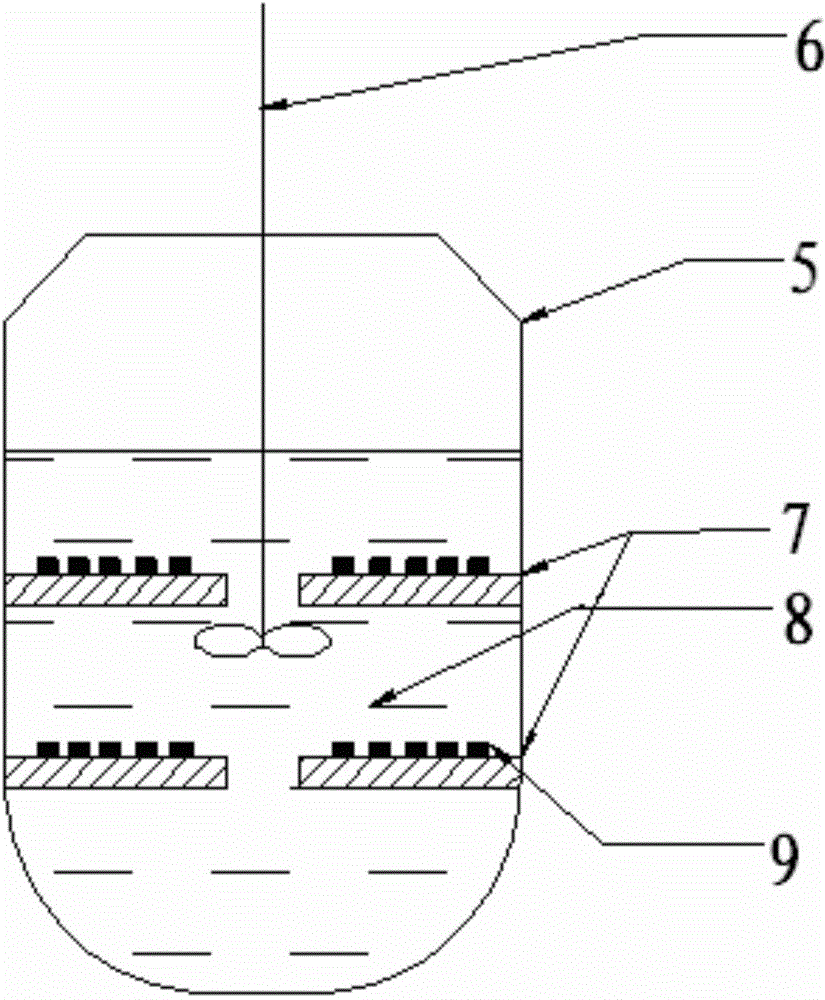

[0059] (2) Get 50 above-mentioned polycrystalline diamond composite sheets with polytetrafluoroethylene layers, place them in a high-pressure reactor, and then add 500 mL of industrial hydrochloric acid with a concentration of 36%. The structural representation of the high pressure reactor is as figure 2 As sho...

Embodiment 2

[0063] (1) Take the 1913 type polycrystalline diamond composite sheet produced by Henan Jingrui Superhard Material Co., Ltd., first wash it with acetone for 45 minutes, remove the oil stain on the surface of the polycrystalline diamond composite sheet, and then sandblast the cleaned polycrystalline diamond composite sheet Treat for 40s, and then conduct electrospray plating under the condition of 5m / s for 100s to obtain a polycrystalline diamond composite sheet with a polytetrafluoroethylene layer; The bottom surface and all side surfaces of the substrate and some side surfaces of the polycrystalline diamond layer, the thickness of the polytetrafluoroethylene layer is 1.0mm.

[0064] (2) Get 50 above-mentioned polycrystalline diamond composite sheets with polytetrafluoroethylene layers, place them in a high-pressure reactor, and then add 500 mL of industrial hydrochloric acid with a concentration of 36%. The structural representation of the high pressure reactor is as figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com