A piston rod seal assembly for a hot air engine

A technology for sealing components and piston rods, which is used in the sealing of engines, hot gas variable capacity engine devices, engine components, etc., can solve problems such as easy oil leakage, poor reliability, and working fluid pollution, and achieve pollution prevention and good results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

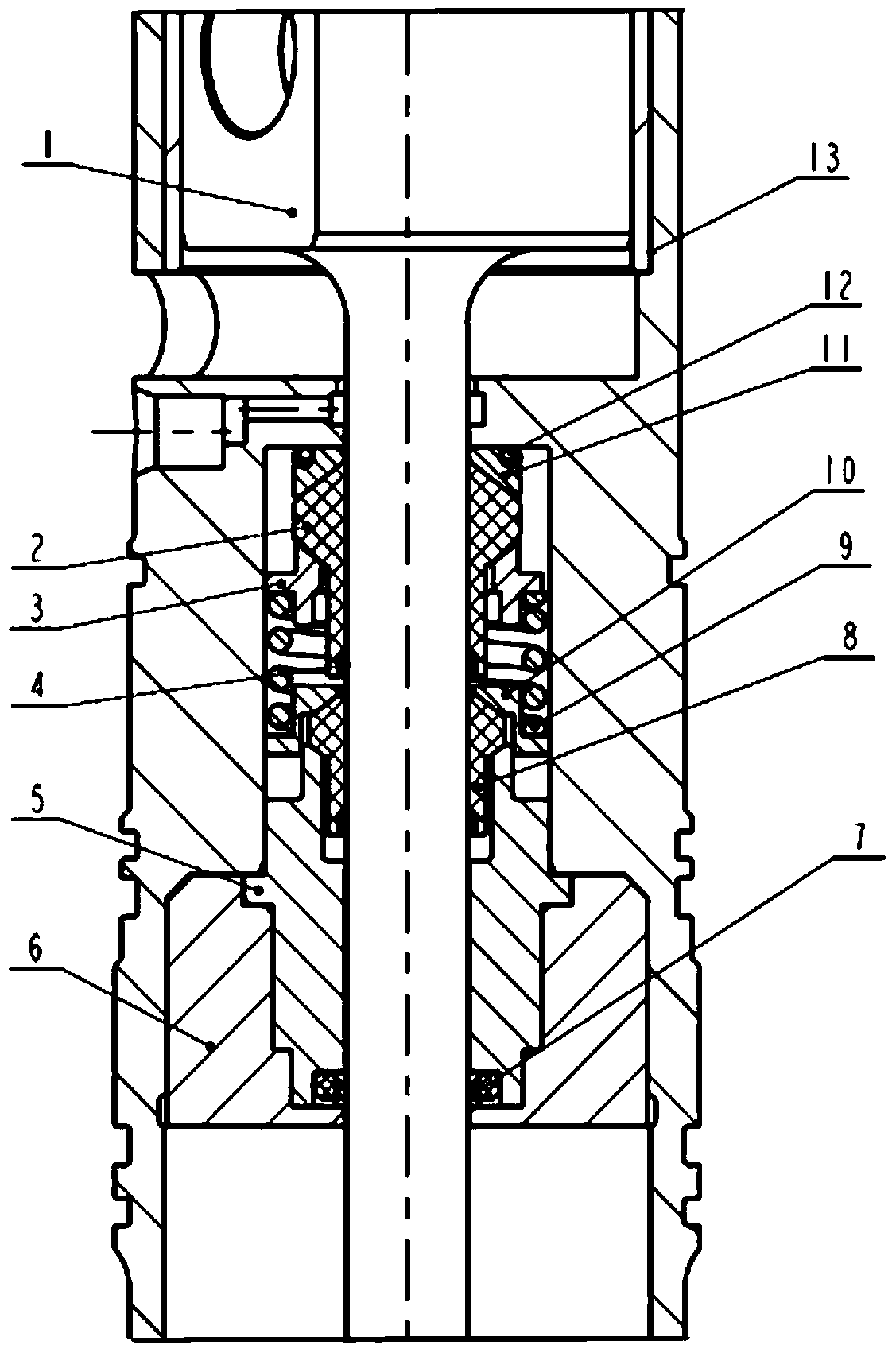

[0015] like figure 1 As shown, the piston rod seal assembly for a hot air engine is composed of a cap seal 7 sleeved on the piston rod 1, a main seal assembly, an auxiliary main seal assembly and a gland 6. The main seal assembly consists of a conical seat 11, The main seal 2, the main seal gland 3 and the spring 9 are composed. The auxiliary main seal assembly is arranged between the main seal assembly and the cap seal 7. The auxiliary main seal assembly consists of the auxiliary main seal 8, the auxiliary main seal gland 10 and the spring 9. The structure of the auxiliary main seal 8 is similar to that of the main seal 2. It is a rod seal sleeved on the piston rod 1, and its outer side is provided with two upper and lower conical bosses. The lower end of the boss is against the conical surface. On the corresponding conical surface boss of the spring seat 5 , the upper conical surface of the boss is pressed by the corresponding conical surface boss of the auxiliary main seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com