Rotational flow water film cooling type combustion chamber

A technology of combustion chamber and film cooling, which is applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of combustion chamber and high-temperature combustion chamber that do not allow oxygen, and achieve simple structure, easy processing and production and popularization and use , the effect of lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

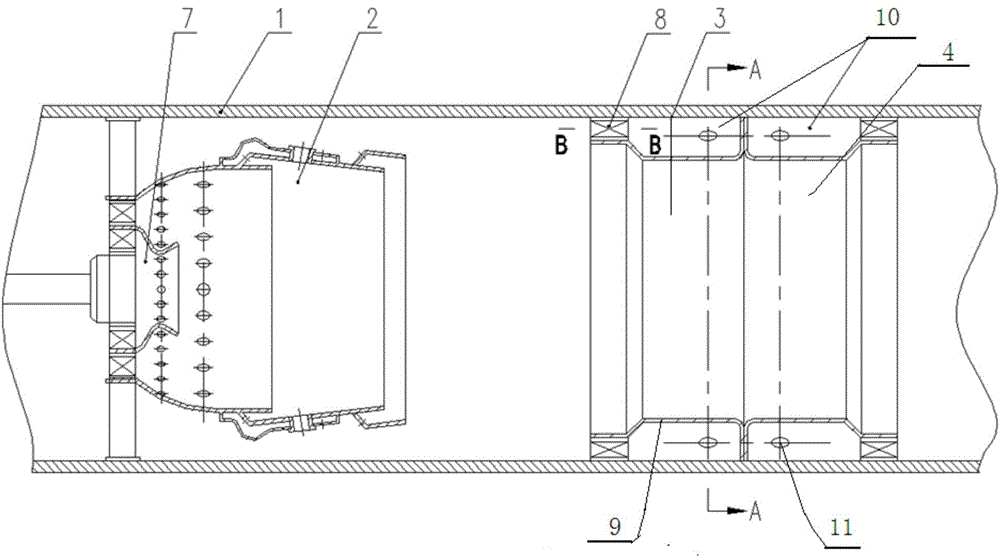

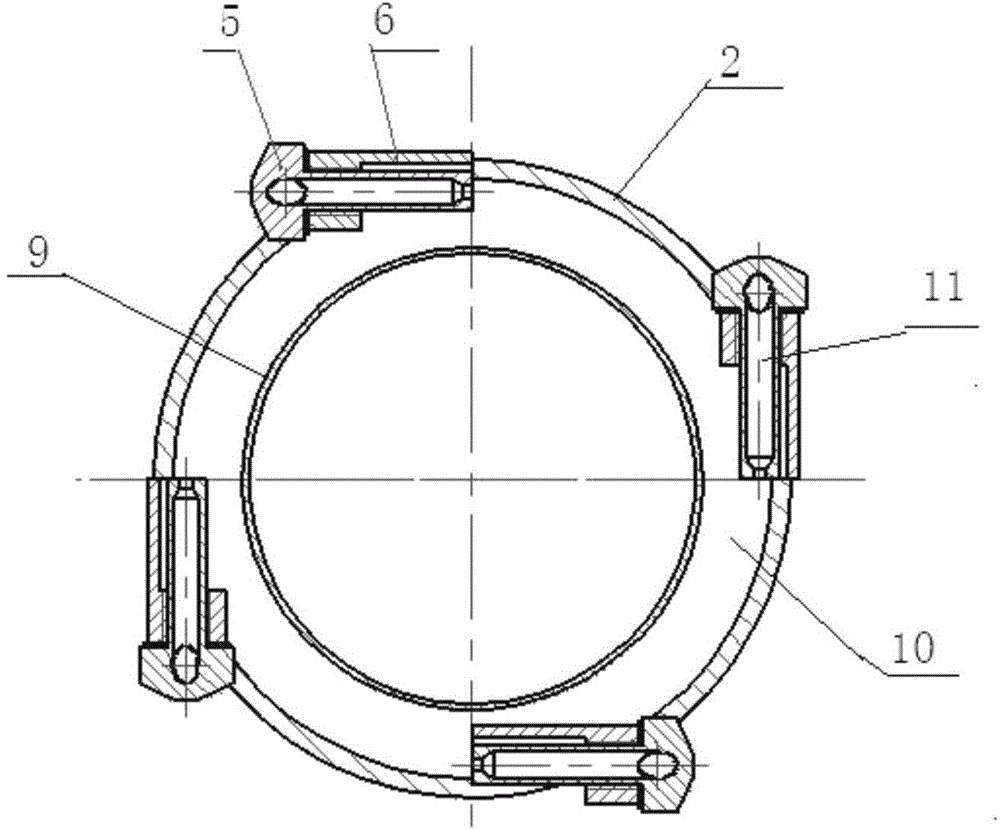

[0019] The swirling water film cooling type combustion chamber of the present invention will be further described below by means of embodiments and in conjunction with the accompanying drawings.

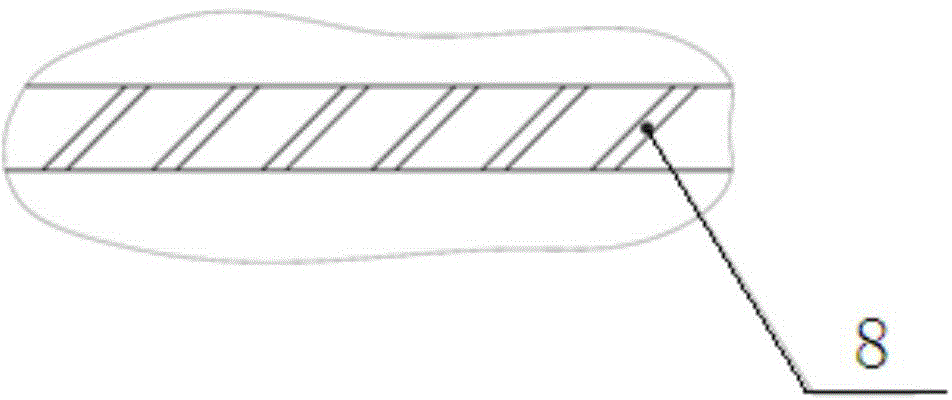

[0020] The swirling water film cooling combustor in this embodiment is used for oil drilling, and its structure is as follows figure 1 , figure 2 As shown, it includes a chamber wall 1, a flame tube head 2 installed in the combustion chamber, a first swirler 3 and a second swirler 4; the flame tube head has a premixing chamber 7, and the first swirler The first cyclone 3 and the second cyclone 4 have the same structure, and both are composed of a cylinder 9, a nozzle 5, a mounting seat 6 and a swirl vane 8. The outer surface of the cylinder 9 and the inner surface of the chamber wall 1 are closed at one end, An annular body water chamber 10 with one end open, swirl blades 8 are installed at the opening end of the annular body water chamber, there are 4 nozzles 5, and the number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com