Design method for shrinkage tooth curved-tooth noncircular bevel gear

A non-conical gear, design method technology, applied to components with teeth, belts/chains/gears, calculations, etc., can solve the problems of straight tooth non-conical processing difficulties, poor versatility, and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The parameters of known non-circular gears are as follows

[0071] Table 1 gear parameters

[0072]

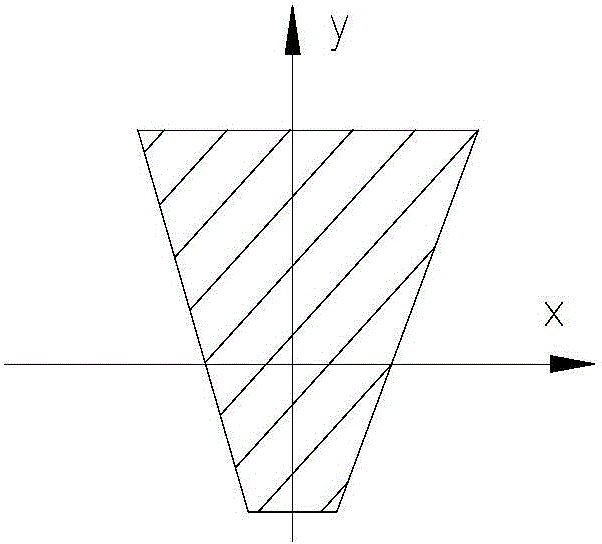

[0073] The normal surface shape of the spiral bevel gear milling cutter corresponding to the parameters in the above table, and its corresponding coordinates (x v ,y v ),Such as figure 1 Shown:

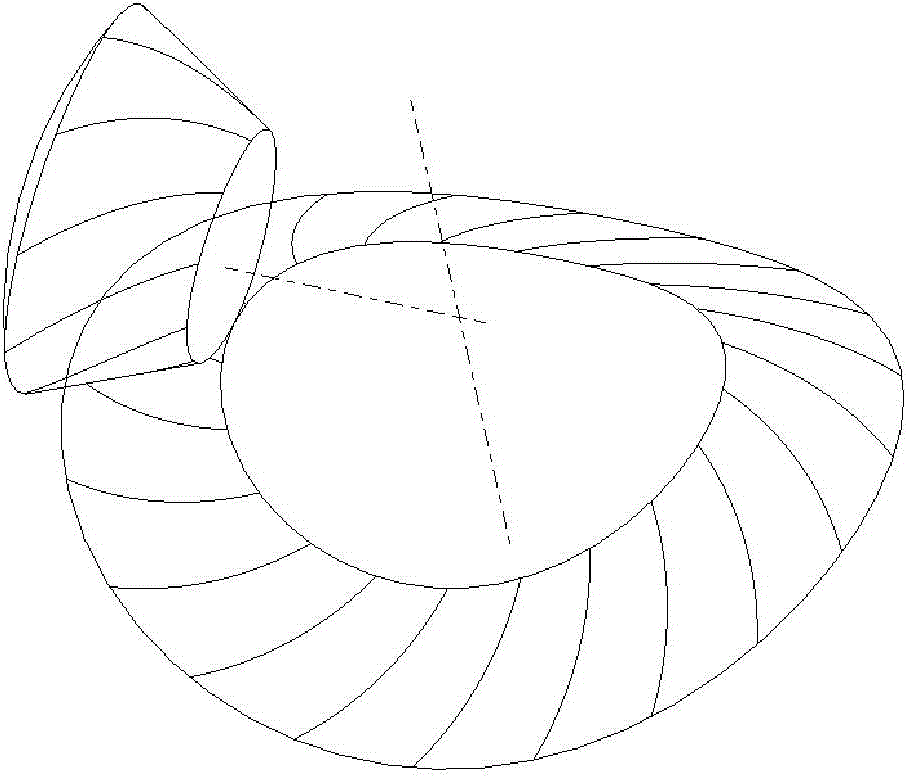

[0074] 1. Determine the pitch cone surface of the shrinking arc tooth non-conical gear

[0075] According to the transmission ratio given above, the pitch angles of the driving and driven wheels are obtained according to formula (2), which are respectively:

[0076]

[0077] Therefore, the pitch cone surfaces of the driving and driven wheels are obtained according to formula (1), which are respectively:

[0078]

[0079]

[0080] its shape like figure 2 shown.

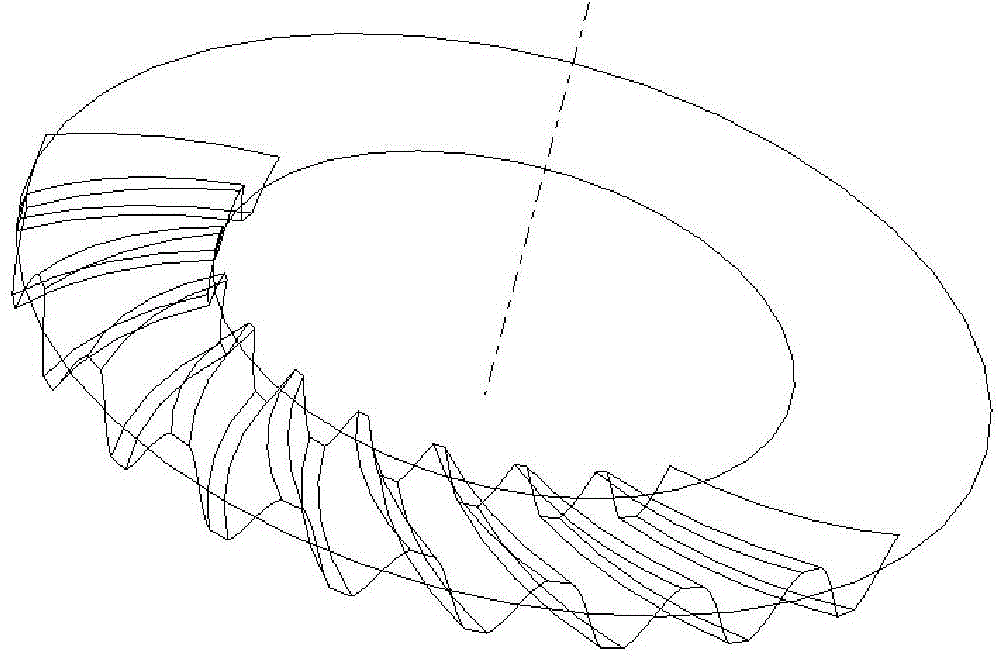

[0081] 2. Determining the parameters of shrinking arc tooth non-conical gear

[0082] 1. Calculate the tip cone angle δ according to formula (9) according to the modulus m of the gear milling cutter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com