Carbon-fluoride-based primary lithium battery and preparation method and detection method thereof

A carbon fluoride, based lithium technology, applied in primary batteries, primary battery use/maintenance, non-aqueous electrolyte batteries, etc., can solve the problem of accelerating the migration rate of lithium ions and discharge products, reducing battery capacity, and rarely commercializing batteries And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

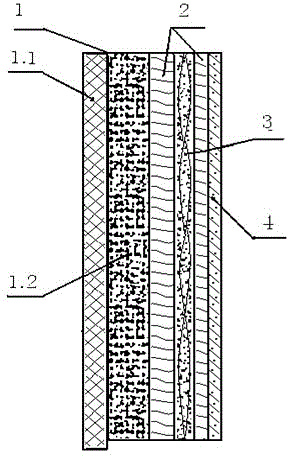

[0041] Embodiment 1, as figure 1 Shown is a basic embodiment of the carbon fluoride-based lithium primary battery of the present invention. A carbon fluoride-based lithium primary battery, comprising a positive electrode sheet 1, a negative electrode sheet 4, a separator 3 and an electrolyte 2; the positive electrode sheet 1 is made of a conductive metal foil or a mesh 1.1 as a collector and attached to the conductive metal foil or the composite slurry 1.2 on the net; the composite slurry 1.2 includes carbon fluoride, or a modified material of carbon fluoride; the negative electrode sheet 4 is made of lithium metal, or a modified material of lithium metal, or contains metal Lithium alloy material; The electrolyte 2 is an electrolyte with functional additives, including non-aqueous electrolytes and functional additives added therein at least for improving battery rate performance; the functional additives in the electrolyte 2 The content is 0.01% to 10% in volume percentage; t...

Embodiment 2

[0043] Embodiment 2 is a preferred embodiment of the carbon fluoride-based lithium primary battery of the present invention. The difference from Example 1 is that in the carbon fluoride-based lithium primary battery, the content of the functional additive polyethylene glycol octylphenyl ether (Trition 100, (C2H4O)nC14H22O) in the electrolyte is 0.01%~1%.

Embodiment 3

[0044] Embodiment 3 is a further embodiment on the basis of Embodiment 1. In the carbon fluoride-based lithium primary battery, the functional additive also includes a composition of one or more of SEI film-forming agent, anti-overcharge additive, flame retardant and stabilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com