Internal combustion engine control device and method

A control device and control method technology, applied in engine control, internal combustion piston engine, valve device, etc., can solve the problems of small response delay of variable compressor mechanism and easy knocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

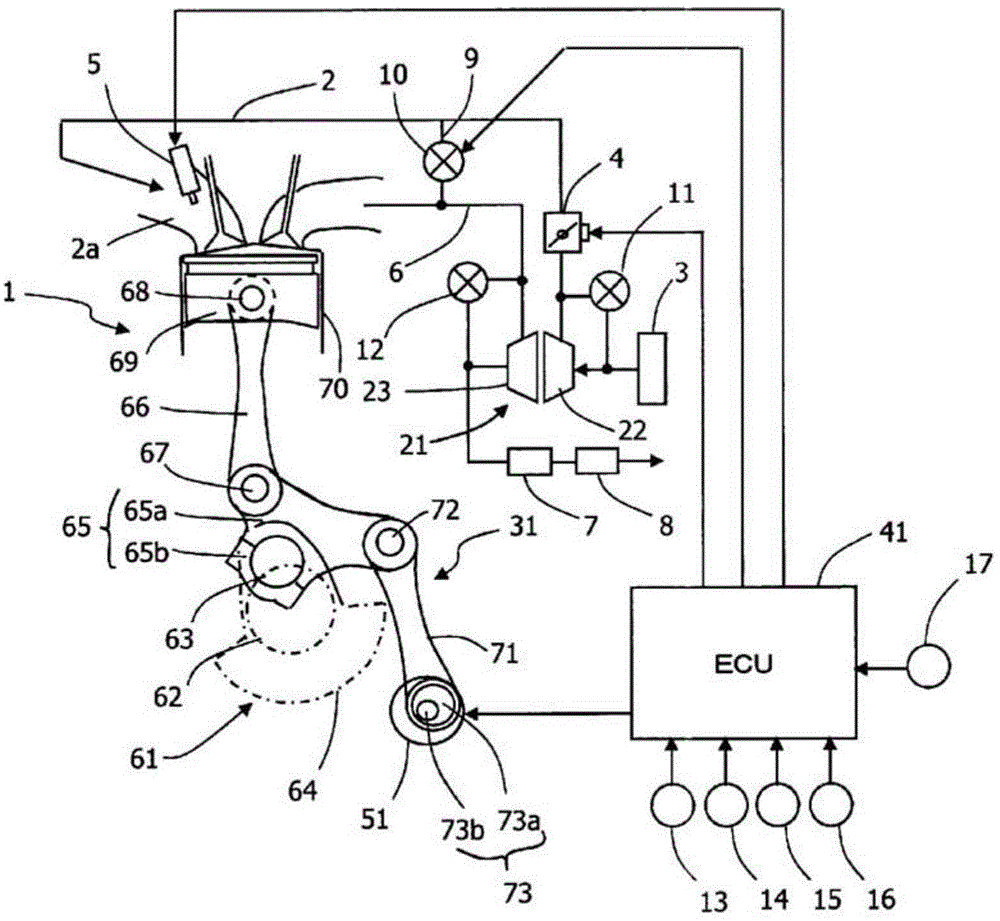

[0022] Embodiments of the present invention will be described below with reference to the drawings.

[0023] figure 1 The outline of the engine system of the first embodiment is shown.

[0024] On the intake passage 2 of the engine (internal combustion engine) 1, an air cleaner 3, a compressor 22 of an exhaust turbocharger 21, an electronically controlled throttle valve 4 for adjusting the amount of intake air are mounted from the upstream side, and A fuel injection valve 5 is attached to the intake port 2a portion.

[0025] In the exhaust passage 6, a turbine 23 of an exhaust turbocharger 21, an exhaust purification catalytic device 7 for purifying exhaust gas, and a muffler 8 are attached from the upstream side.

[0026] In addition, an EGR passage 9 connecting the exhaust passage 6 between the engine 1 and the exhaust purification catalytic device 7 and the intake passage 2 downstream of the throttle valve 4 is arranged, and an EGR control device for adjusting the amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com