Stirrup box capable of compressing and orderly releasing spiral continuous stirrups

A technology of stirrup boxes and stirrups, applied in the field of stirrup boxes, can solve the problems of single steel bar skeleton style, and achieve the effects of saving molding time, improving work efficiency, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

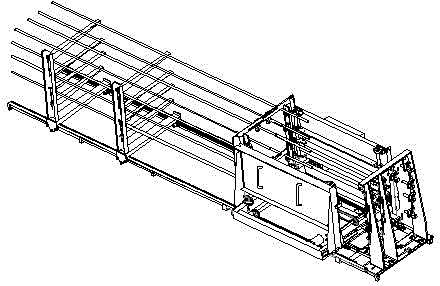

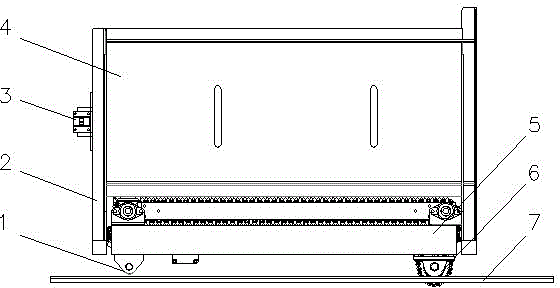

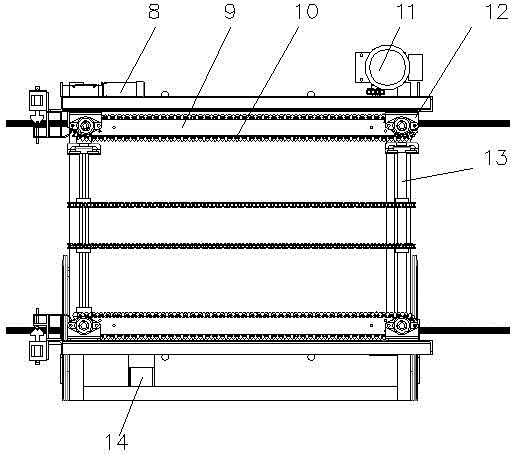

[0033] Such as figure 1 As shown, the stirrup box of the present invention, which can store and release spiral continuous stirrups in an orderly manner, is a key component of the steel skeleton forming machine. Such as figure 2 , image 3 , Figure 4 As shown, the stirrup box of the present invention includes a luffing device for adjusting the cross-sectional size of the stirrup box, a walking device for moving the stirrup box along the direction of the longitudinal bars, and a release device for storing and orderly releasing spiral continuous stirrups. Rib device. Wherein, the luffing device includes a chain transmission mechanism and a screw mechanism, and the sprocket of the chain transmission mechanism is coaxially connected with the lead screw 15 of the screw mechanism; The stirrup box moves as a whole; the tendon releasing device includes a chain transmission mechanism, the sprocket shaft 13 is arranged vertically and horizontally, the transmission direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com