Automatic folding device for refractory fiber needled carpet folding block

A refractory fiber and folding device technology, applied in the mechanical field, can solve the problems of high comprehensive cost, low production efficiency, and product quality impact, and achieve the effects of high efficiency, reliable performance, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

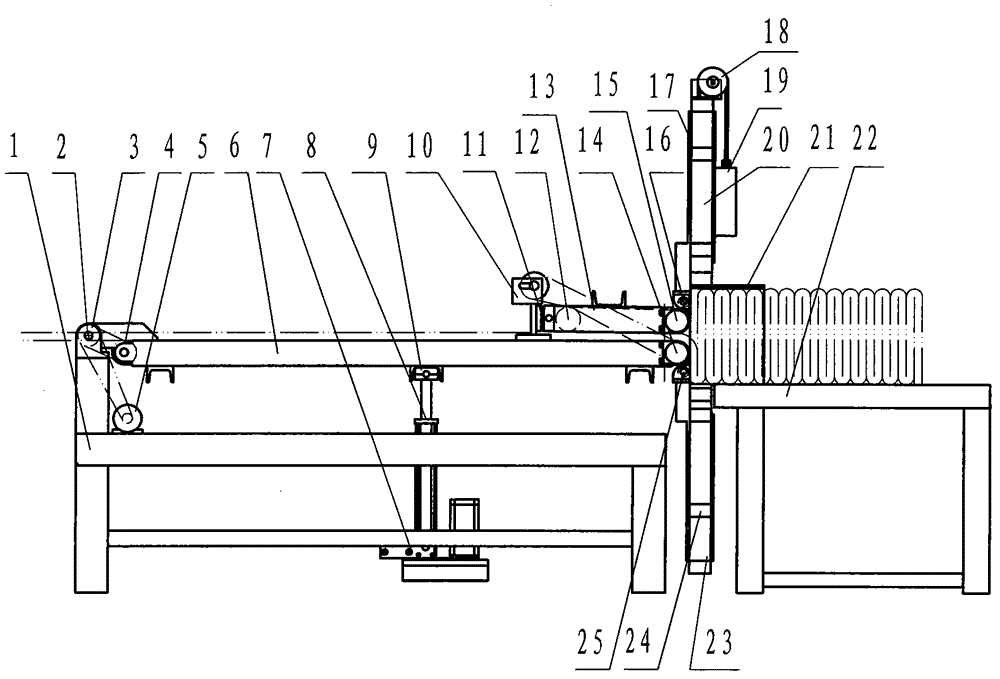

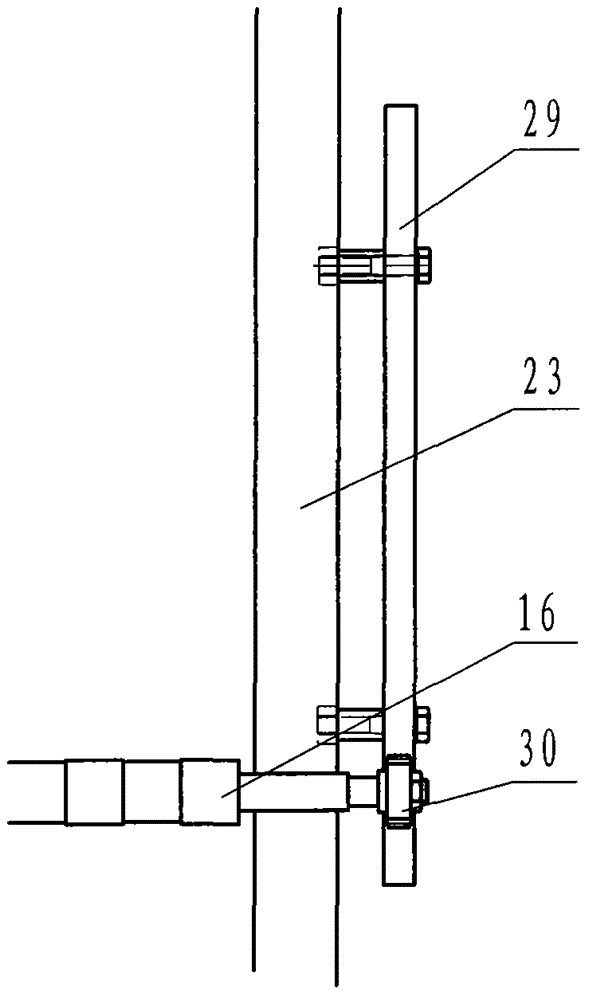

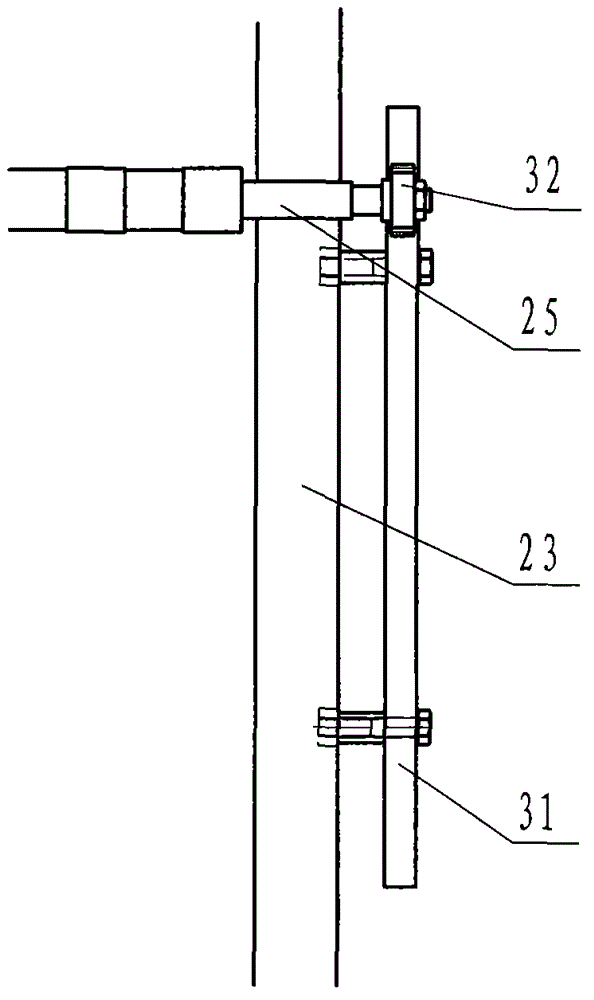

[0013] Such as figure 1 As shown, an automatic folding device for refractory fiber acupuncture blanket folding blocks is mainly composed of a frame 1, a motor 5, a pin shaft 2, a bridge sprocket 3, a feeding bracket 6, a feeding roller 4, a feeding roller 14, an inverted Composed of sprocket 10, hinge 11, pressing roller 12, pressing roller 15, pressing bracket 13, and forming platform 22, a motor 5 is installed in the middle of the left end of the frame 1, and a pin shaft is installed in the upper left end of the frame 1 2. The bridge sprocket 3 is installed on the pin shaft 2, the motor 5 is connected with the bridge sprocket 3 through a chain, the feeding bracket 6 is installed on the frame 1, and the feeding roller 4 and the feeding roller are respectively installed at both ends of the feeding bracket 6 A conveyor belt 26 is installed between the two feed rollers 4 and the feed roller 14, and the feed roller 4 at the left end is connected with the bridge sprocket 3 through...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap