Hydrous ethanol gasoline and preparation method thereof

A technology for hydrous ethanol and gasoline, applied in the field of petrochemical industry, can solve the problems of large amount of emulsifier, limited capacity, inability to solve the problem of mutual solubility of hydrous ethanol and gasoline, etc., and achieves the effect of simple process formula and convenient storage and transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

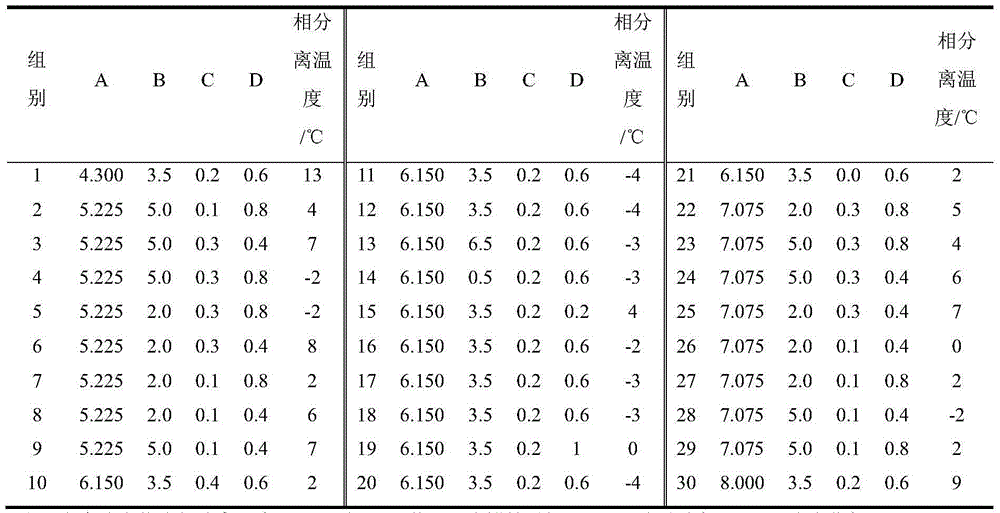

[0019] In order to obtain the optimal stability of ethanol gasoline with a water ethanol ratio of 10% (ethanol degree of 95%), the optimal preparation parameters are sought within a certain range. Among them, the range of component type optimization: HLB value 4.3-8, stirring time 0.5-6.5, co-solvent ratio 0-0.4, emulsifier ratio 0.2-1, the indicator of stability is phase separation temperature (Y); The type of emulsifier is selected as Span 80 + Tween 80, and the type of cosolvent is selected as n-octanol.

[0020] (II) Experimental design:

[0021] Using mathematical statistical software such as SPSS or Design-Expert software or Isight software, the experimental plan and results based on the central combination method design are shown in Table 1.

[0022] Table 1 E10W stability test matrix and results

[0023]

[0024] Note: The response value in the table is phase separation temperature / ℃, A is HLB value, B is stirring time / min, C is cosolvent / %, D is emulsifier / %.

...

Embodiment example 2

[0037] (1) scope of optimization:

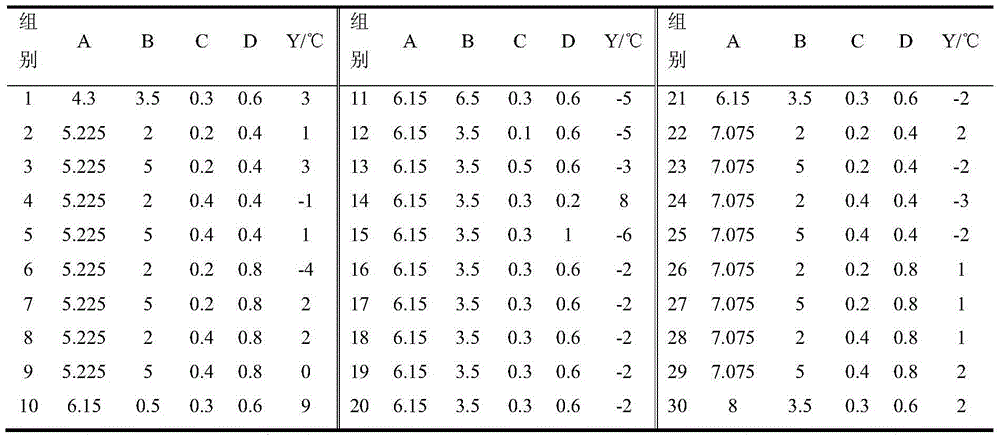

[0038]In order to obtain the optimal stability of ethanol gasoline with a water ethanol ratio of 20% (ethanol degree of 95%), the optimal preparation parameters are sought within a certain range. Among them, the range of component type optimization: HLB value (A) 4.3 ~ 8, stirring time (B) 0.5 ~ 6.5, cosolvent volume ratio (C) 0.1 ~ 0.5%, emulsifier volume ratio (D) 0.2 ~ 1% , and the index to measure the stability is the phase separation temperature (Y). The type of compound emulsifier is selected as Span 80 + Tween 40, and the type of co-solvent is selected as castor oil.

[0039] (II) Experimental design:

[0040] Using mathematical statistical software such as SPSS or Design-Expert software, the experiment was designed based on the central combination method, as shown in Table 2. The response value is the phase separation temperature, and the results are shown in Table 2.

[0041] Table 2 E20W stability test matrix and results

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com