Photoresist-removing water-based stripping liquid composition

A technology of stripping liquid and composition, applied in the direction of photosensitive material processing, etc., can solve the problems of inability to dissolve, easy to block pipelines, and decline in the ability of stripping liquid to remove glue.

Inactive Publication Date: 2015-05-13

SUZHOU RUIHONG ELECTRONIC CHEM CO LTD

View PDF9 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But it has the following disadvantages at the same time: first, it attacks metals such as copper and aluminum, causing corrosion and fracture of metal lines; second, when NaOH and KOH are used as strippers, although they can peel off the photoresist from the substrate, they cannot play a good role. Dissolution, the film slag produced after peeling is too large, difficult to filter, and easy to block the pipeline during recycling

Patent CN1444103, the stripping solution described is composed of organic solvent, organic base and preservative. Due to the high temperature, the organic solvent and organic base are easy to volatilize, but due to the different volatilization speed, after a period of use, the product components will Changes, so that the degumming ability of the stripping solution declines

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

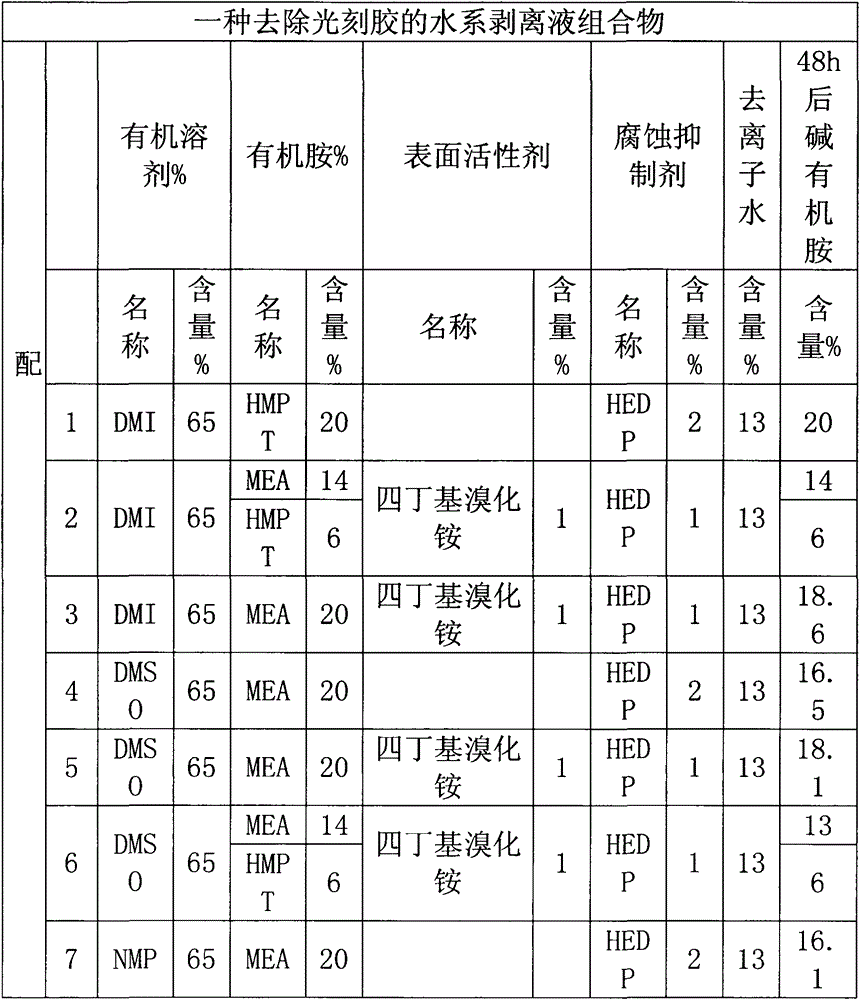

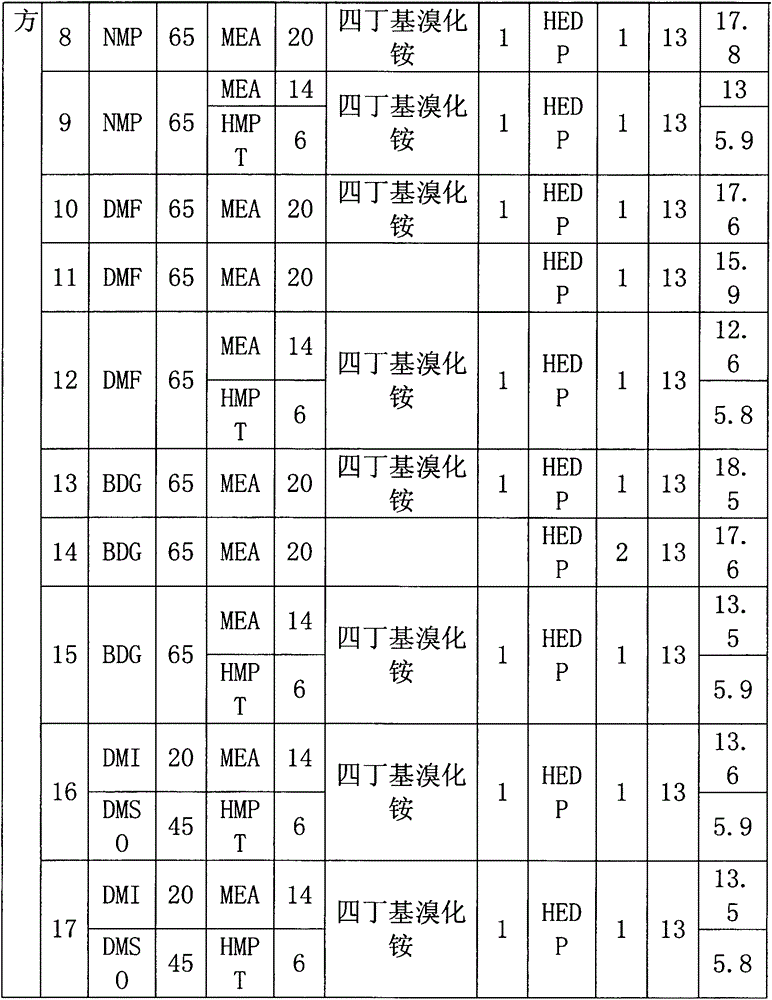

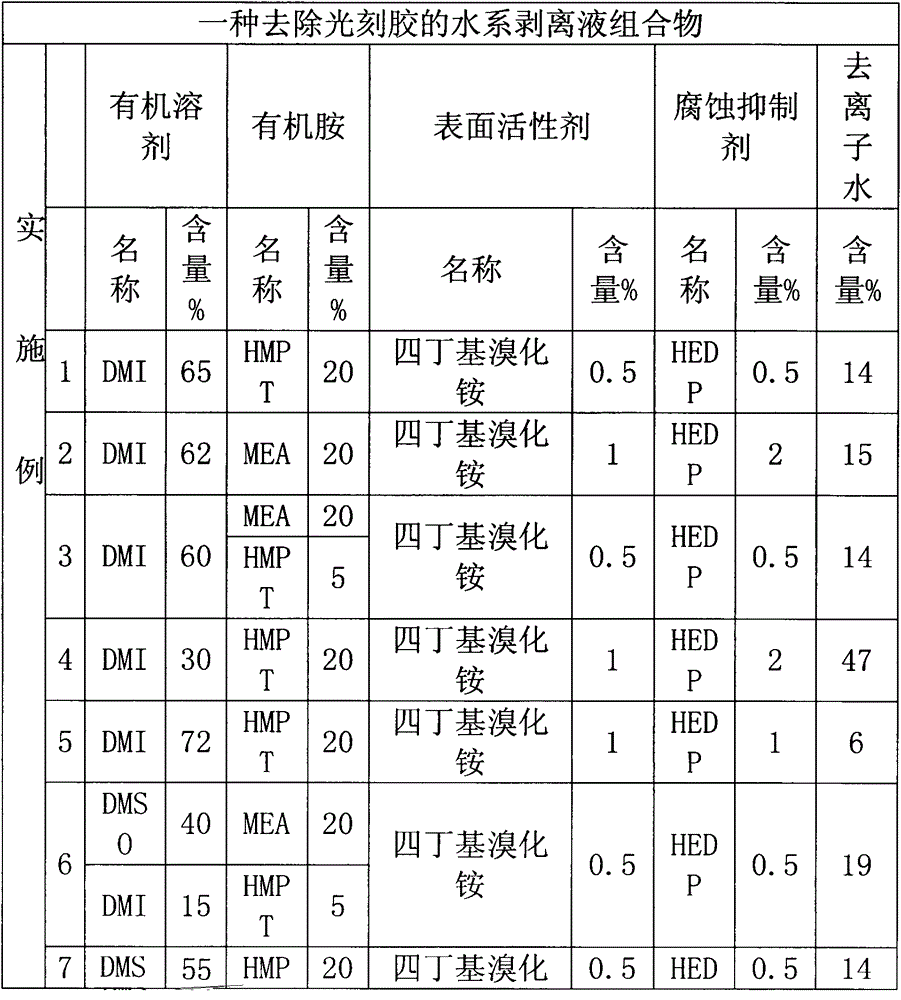

[0022] The present invention is further described below by way of examples, and the present invention is not limited to the scope of the examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a photoresist stripping liquid composition which is mainly used for removing unexposed photoresist in the manufacturing process of a semiconductor device. The photoresist stripping liquid comprises the following components in percentage by mass: 20-70% of a polar solvent, 5-50% of an organic amine compound, 0.01-5% of a surfactant, 0.01-5% of a corrosion inhibitor and 10-60% of deionized water. In the process, the unexposed photoresist in the semiconductor device is removed at a low temperature, corrosion to metal of the semiconductor device is minimized, and a PI bottom film is not swelled.

Description

technical field [0001] The invention relates to a water-based stripping solution composition for photoresist in a semiconductor manufacturing process. The stripping solution can effectively remove unexposed photoresist, and does not corrode the substrate of a semiconductor device, and has no effect on the PI bottom film. No swelling occurs. Background technique: [0002] Many photoresist strippers have been used as in-line cleaners during the fabrication of large scale integrated circuits. In the manufacturing process, the photoresist film is baked at high temperature, deposited on the wafer substrate, and then imaged into a circuit pattern after exposure and development. After the etch process, the unexposed photoresist must be removed from the protected area of the wafer so that back-end operations can be performed. [0003] In the manufacturing process, since the photoresist and the substrate are required to have good adhesion, high-temperature baking is usually perfo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G03F7/42

Inventor 卞玉桂

Owner SUZHOU RUIHONG ELECTRONIC CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com