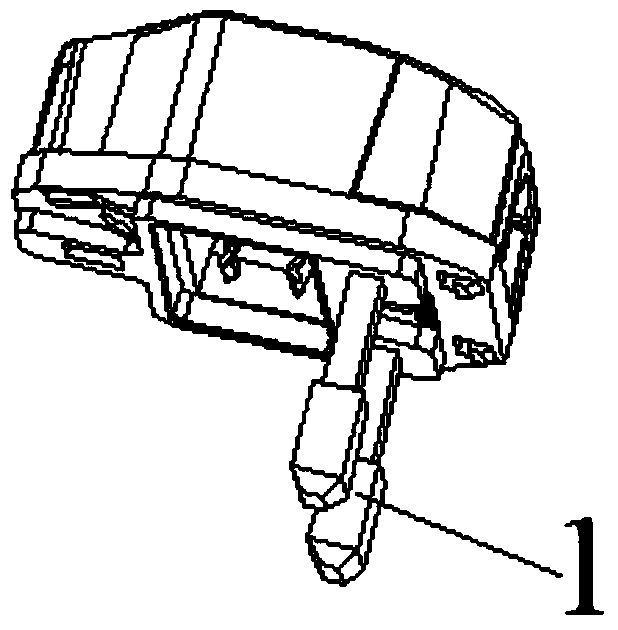

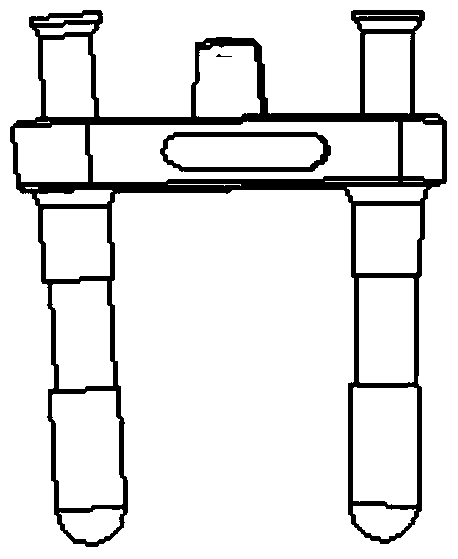

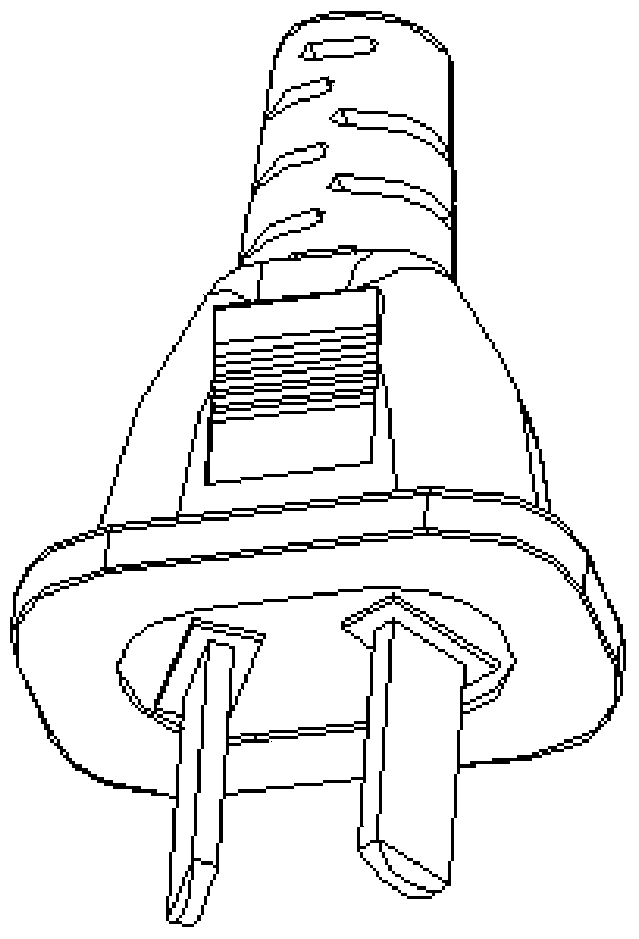

Plug pin manufacturing process

A manufacturing process and pin technology, which is applied in the field of pin preparation technology, can solve problems such as impact, and achieve the effects of simple process steps, excellent processing performance, and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The plug pin manufacturing process includes the following steps:

[0031] 1) Die casting

[0032] First, the zinc block is melted at 420°C, and then the molten zinc block is fed into the forming mold, and die-casted into a rough blank of the plug pin; the forming mold can be selected according to the shape and size of the plug pin to be formed, namely The forming mold is replaceable;

[0033] 2) Electroplated red copper

[0034] A layer of red copper is plated on the outer surface of the rough embryo of the plug pin obtained in step 1; the process of electroplating red copper is as follows, first, the rough embryo of the plug pin is degreased and derusted with sulfuric acid, washed with water, dried, and finally placed in copper electroplating Plating red copper in the solution, because zinc belongs to relatively active metal, easy to oxidize, rust and turn black, so it is necessary to use acid to remove oil and rust. The copper electroplating solution includes copper...

Embodiment 2

[0038] The plug pin manufacturing process includes the following steps:

[0039] 1) Die casting

[0040] First, the zinc block is melted at 400°C, and then the molten zinc block is fed into the forming mold, and die-casted into a rough blank of the plug pin; the forming mold can be selected according to the shape and size of the plug pin to be formed, namely The forming mold is replaceable;

[0041] 2) Electroplated red copper

[0042] A layer of red copper is plated on the outer surface of the rough embryo of the plug pin obtained in step 1; the process of electroplating red copper is as follows, first, the rough embryo of the plug pin is degreased and derusted with sulfuric acid, washed with water, dried, and finally placed in copper electroplating Plating red copper in the solution, because zinc belongs to relatively active metal, easy to oxidize, rust and turn black, so it is necessary to use acid to remove oil and rust. The copper electroplating solution includes copper...

Embodiment 3

[0046] The plug pin manufacturing process includes the following steps:

[0047] 1) Die casting

[0048] First, the zinc block is melted at 450°C, and then the molten zinc block is fed into the forming mold, and die-casted into a rough blank of the plug pin; the forming mold can be selected according to the shape and size of the plug pin to be formed, namely The forming mold is replaceable;

[0049] 2) Electroplated red copper

[0050] A layer of red copper is plated on the outer surface of the rough embryo of the plug pin obtained in step 1; the process of electroplating red copper is as follows, first, the rough embryo of the plug pin is degreased and derusted with sulfuric acid, washed with water, dried, and finally placed in copper electroplating Plating red copper in the solution, because zinc belongs to relatively active metal, easy to oxidize, rust and turn black, so it is necessary to use acid to remove oil and rust. The copper electroplating solution includes copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com