Processor, device, method and computer program to control multi-phase rotating field motor

A rotating magnetic field, processor technology, applied in the direction of controlling generators, controlling electromechanical brakes, current controllers, etc., can solve the problems of high cost, high cost accumulation, large volume and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

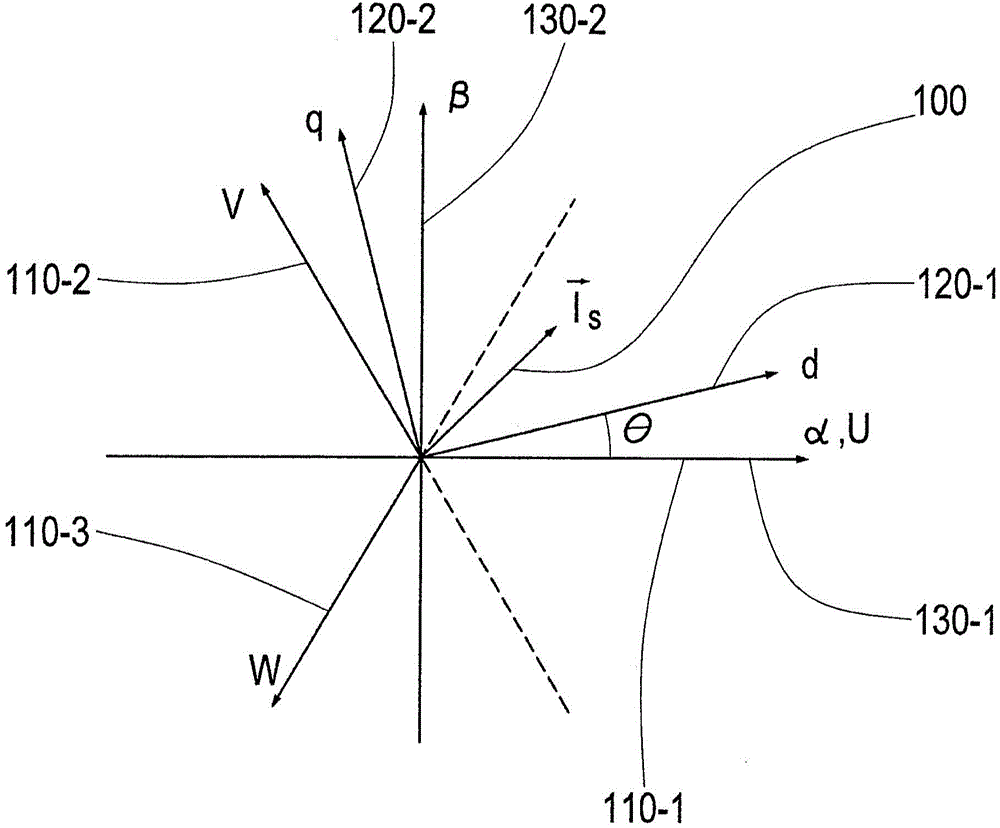

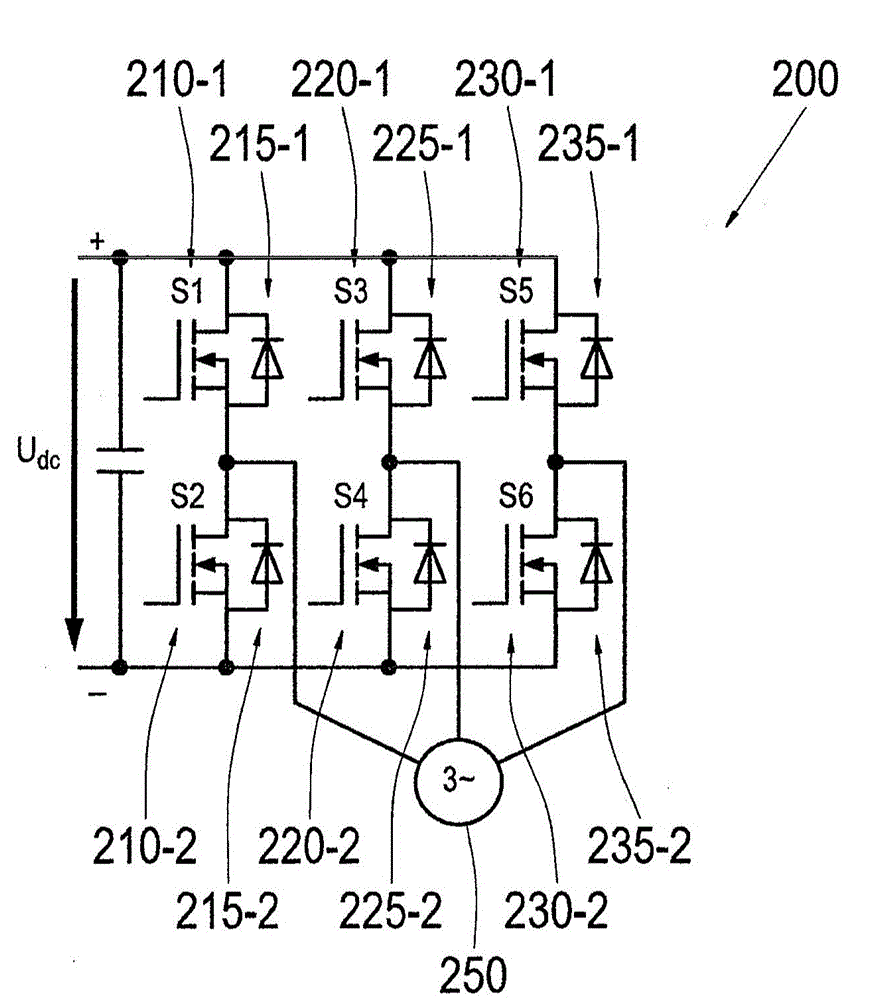

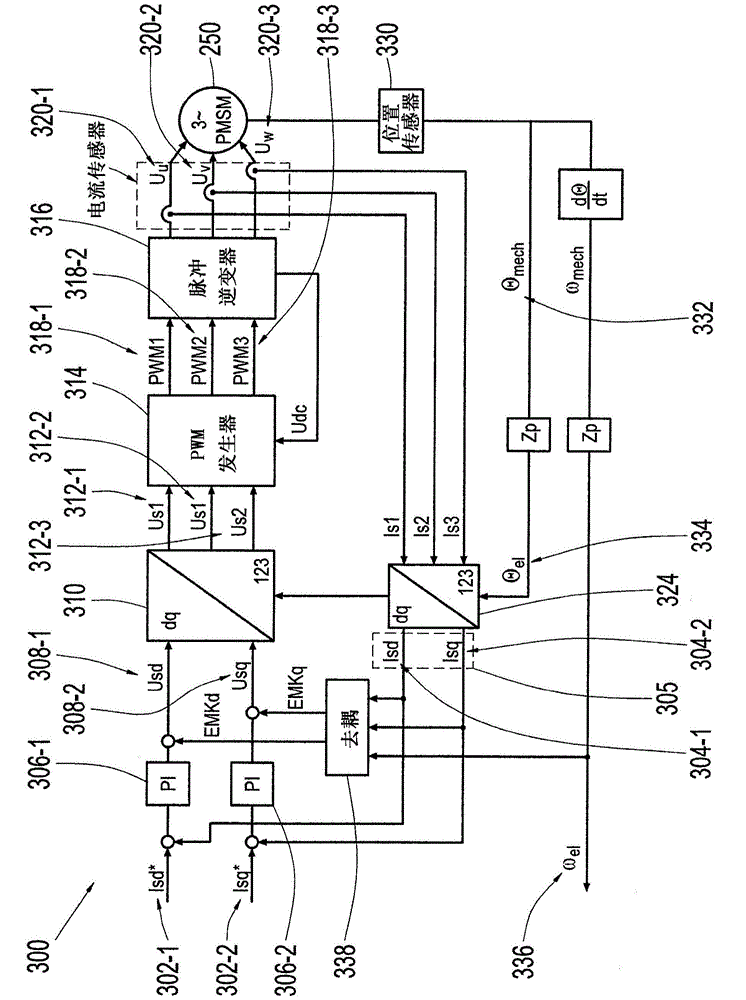

[0033] Various embodiments are now described in more detail with reference to the accompanying drawings in which some embodiments are shown. In the drawings, the thickness dimensions of lines, layers and / or regions may be shown exaggerated for clarity.

[0034] In the ensuing description of the drawings showing only some exemplary embodiments, the same reference numerals may denote the same or similar parts. Furthermore, general reference signs may be used for parts and objects that appear multiple times in one embodiment or one figure but are described in common with respect to one or more features. Parts or objects described with the same or general reference numerals may be identical in single, multiple or all features, such as their specifications, but may also be implemented differently if necessary, as long as it is not clear from the description or get other parts or objects implicitly.

[0035] Although the embodiments may be modified and changed in various ways, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com