Preparation method of sauce

A production method and technology of soy sauce, which is applied in the field of soy sauce processing, can solve the problems of limited promotion range of iron-fortified soy sauce, immature technology and unsatisfactory technology, and achieve the effects of high amino acid types and content, bright red color and sweet taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] According to the ratio of 85 parts of soybeans, 15 parts of flour and 1 part of wheat koji, prepare soybeans, flour and wheat koji, wherein the soybeans are required to have full grains and no bad material.

[0069] Soak soybeans in water for 3 hours, pressurize to 0.12MPa at 120°C and cook for 10 minutes, then lower the temperature to 60°C under a negative pressure of 0.08MPa for 1 hour, and take them out of the pot; the whole process takes 2 hours. Afterwards, the steamed clinker is cooled to 40° C., mixed with the amount of flour and wheat koji, and fermented at 40° C. to obtain unstrained spirits koji. The whole preparation time is no more than 72 hours.

[0070] Afterwards, put 80 parts of prepared fermented unstrained spirits koji in the fermentation tank, and add 15 parts of 17% salt water to ferment in the open sun for more than one year. Mature. In the process of fermentation in the open sun, the fermented soy sauce is exposed to the sun and exposed to the nig...

experiment example 1

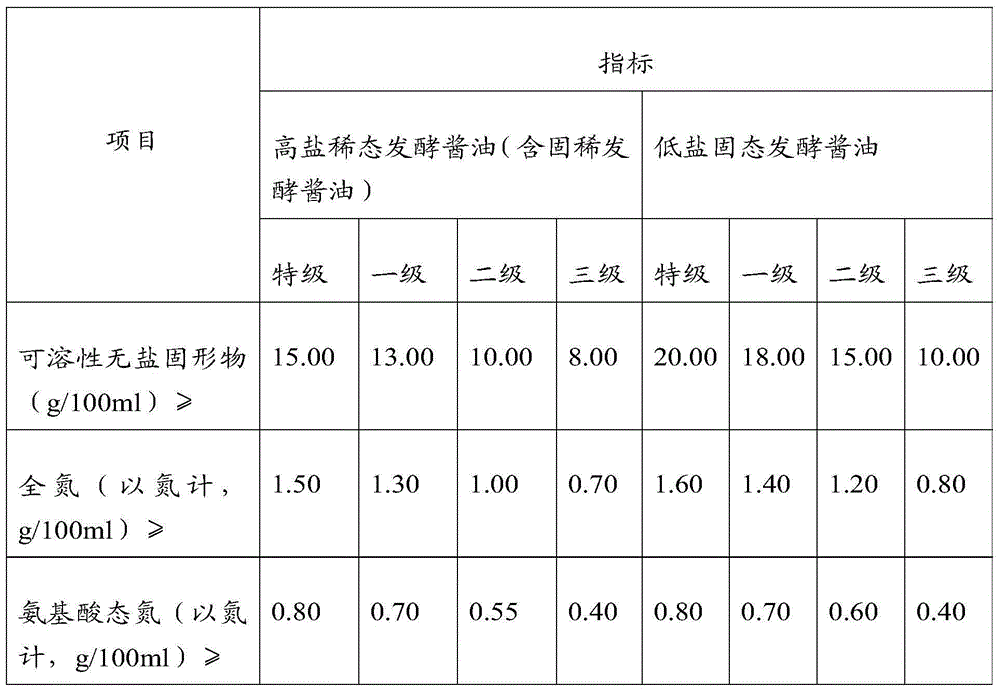

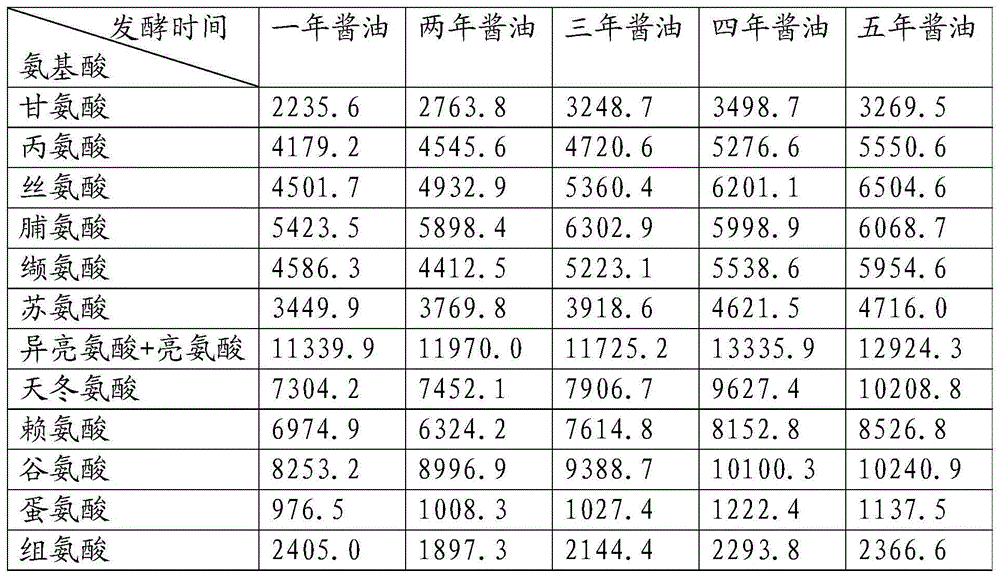

[0083] According to the soy sauce that the method that the embodiment of the present invention 1 provides provides, its amino acid content table is as follows (unit: mg / kg):

[0084]

[0085]

experiment example 2

[0087] The color values of soy sauce in each of the above years are detected as follows:

[0088] Color value

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com