Tilting type material stumbling device for cold rolling and spinning

A technology of laying head and laying mouth, which is applied in the direction of metal rolling, metal rolling, bending workpiece, etc., can solve the problems of difficult quality control of cold-rolled wire, uncontinuous production, large energy consumption, etc., and save energy. The effect of consumption, improvement of production environment and smooth wire conveyance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to better understand and implement the technical solutions of the present invention, some embodiments of the present invention are provided here. These examples are for better explaining the technical solutions of the present invention, and do not constitute any form of limitation to the present invention.

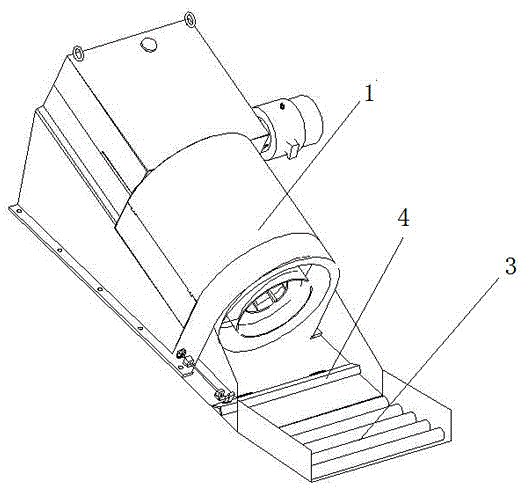

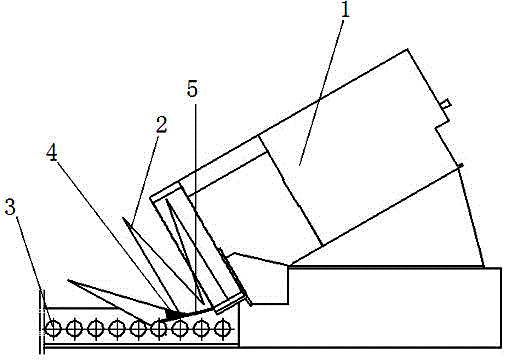

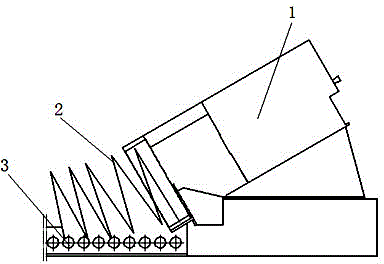

[0010] The cold-rolled silk dumping and tripping device is used in the production of cold-rolled wire rods. The cold-rolled spinning and dumping device is arranged below the rear part of the cold-rolling spinning machine, and the cold-rolling spinning The dumping and tripping device is a blocking rod fixed under the rear part of the spinning mouth of the cold-rolled laying machine. The blocking rod is arranged behind the blanking part of the spinning machine. There are at least two blocking rods. The blocking rod is a horizontal bar fixedly arranged under the rear part of the spinning mouth of the laying machine. The horizontal bar has a slope from bottom to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com