Metal energy storage spring machining method

A technology of energy storage springs and processing methods, which is applied in the direction of springs, etc., can solve problems such as easy failure in use, failure to restore the end of the steel strip, failure to meet the requirements of design drawings, etc., and achieve the effects of easy repair, high yield, and reliable processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A metal energy storage spring processing method, said method is completed by the following steps:

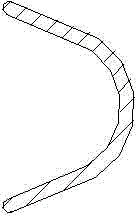

[0027] The first step: first bend the steel strip horizontally into an arc-shaped steel strip;

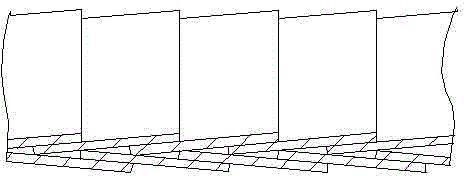

[0028] The second step: spirally wind the arc-shaped steel strip along the longitudinal direction into multiple conical tubes;

[0029] Step 3: Lap each adjacent two conical cylinders among the plurality of conical cylinders to form a long cylinder;

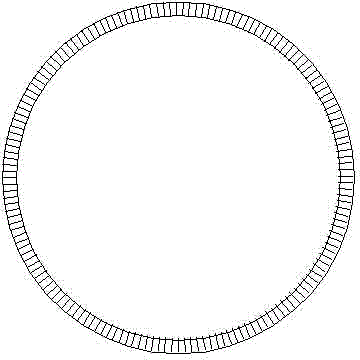

[0030] Step 4: Pull out a single piece of steel strip from the head end and tail end of the long cylinder for butt welding to form an annular cylinder;

[0031] Step 5: After recovering the two single-piece steel strips welded into conical cylinders, they are then wound back into the respective adjacent conical cylinders;

[0032] Step 6: Stamp the ring-shaped barrel obtained in Step 5 to meet the requirements of the drawing, see Figure 1~Figure 3 shown.

Embodiment 2

[0034] In the method for processing metal energy storage springs described in Example 1, in the second step, the inclination angle of each of the tapered cylinders is α=2.8624°.

Embodiment 3

[0036] In the second step of the metal energy storage spring processing method described in Example 1, the circumference of the helix at the small end of the tapered cylinder is 2294.809mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| perimeter | aaaaa | aaaaa |

| perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com