Assembling production line of vacuum boosters

A technology of vacuum booster and assembly production line, which is applied in liquid tightness measurement, assembly machine, transportation and packaging by using liquid/vacuum degree, which can solve the problems of high cost and low efficiency, so as to improve production efficiency and ensure performance , the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

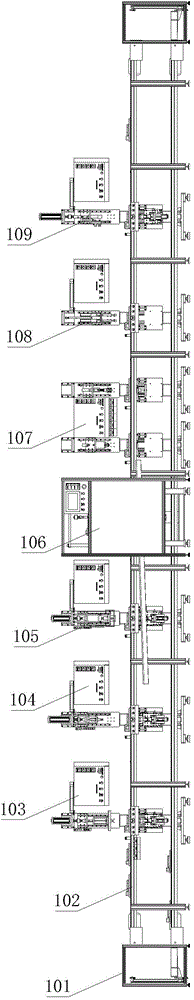

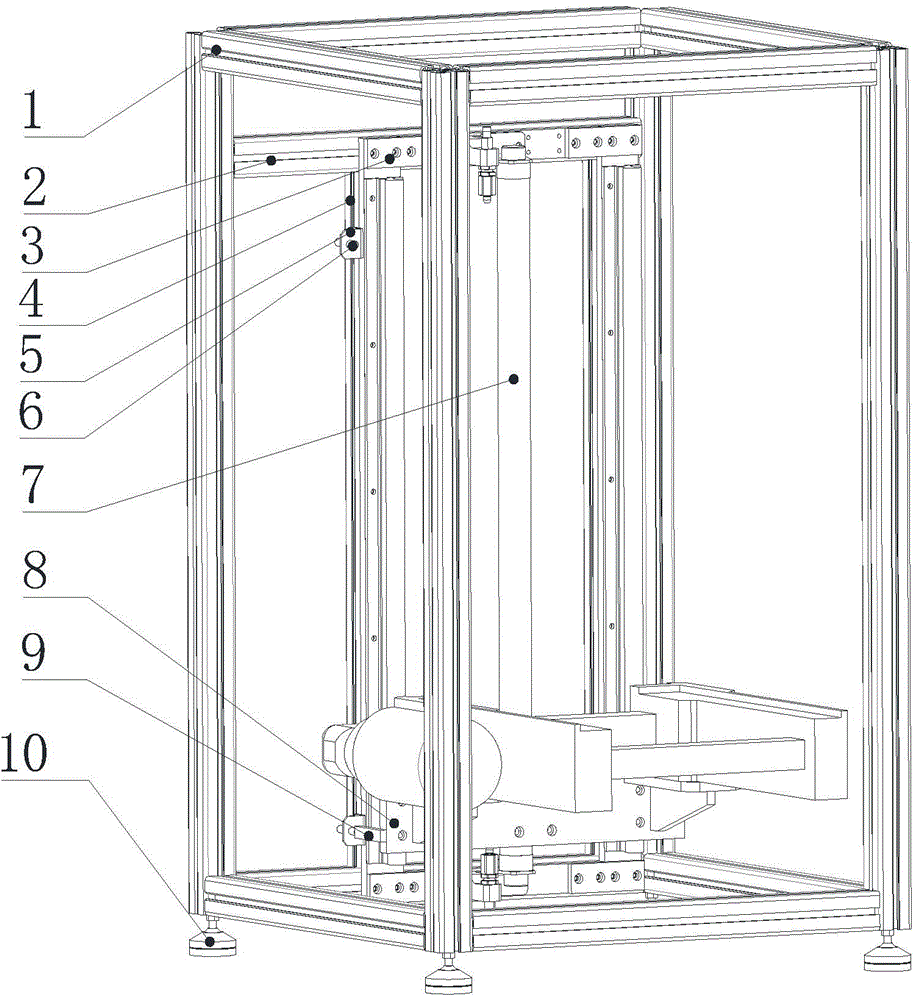

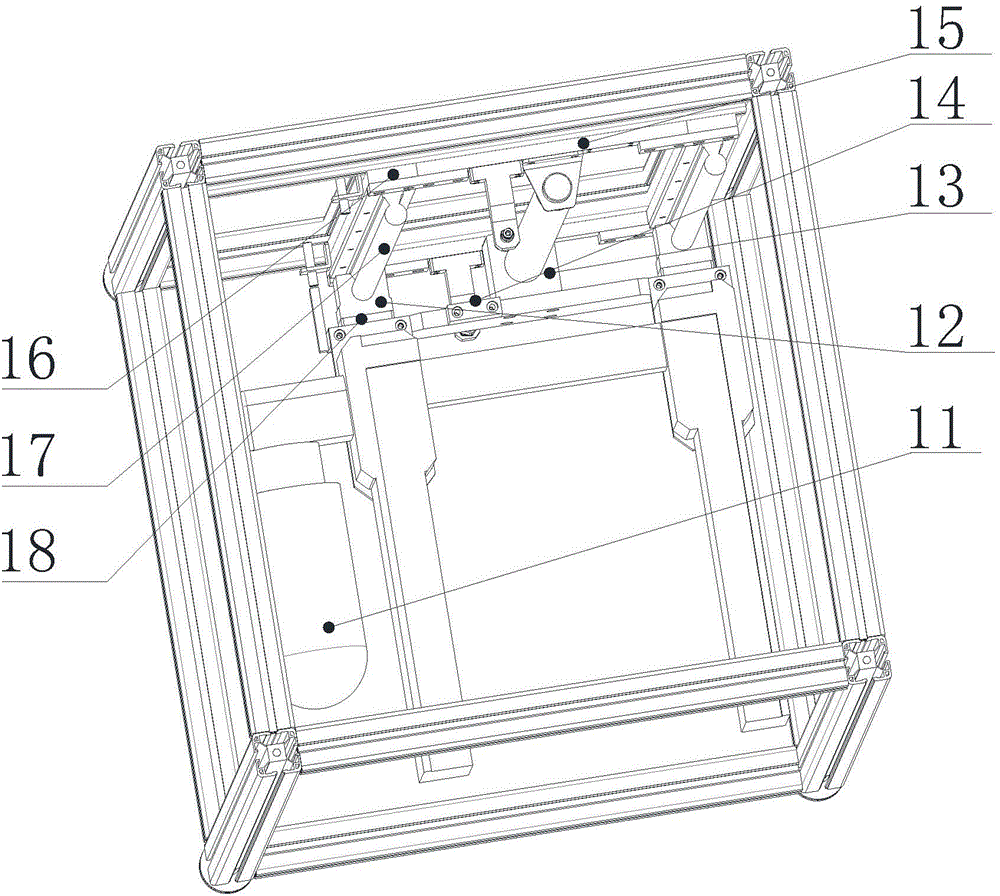

[0027] figure 1 It is a schematic diagram of the overall structure of the present invention; as figure 1 As shown, a vacuum booster assembly production line of the present invention includes a transmission belt 102 driven by a transmission mechanism 101. The transmission mechanism 101 includes a lifting device. On the side of the transmission belt 102, vacuum booster plunger valves are arranged in sequence. Gap detection device 103 with the feedback plate, assembly device 104 between the feedback plate of the vacuum booster and the front housing components, performance detection device 105 of the vacuum booster, closing device 106 of the front and rear shells of the vacuum booster, adjustment and press-fitting of the ejector head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com