Reduction gear milling head with cooling holes

A reduction gear milling head, heat dissipation and cooling technology, applied in the direction of milling machine equipment, milling machine equipment details, maintenance and safety accessories, etc., can solve the problem of low processing efficiency of milling cutters and milling heads, threats to the safety of operators, milling cutters and milling heads Breakage and other problems, to achieve the effect of easy disassembly, reduce wear coefficient and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

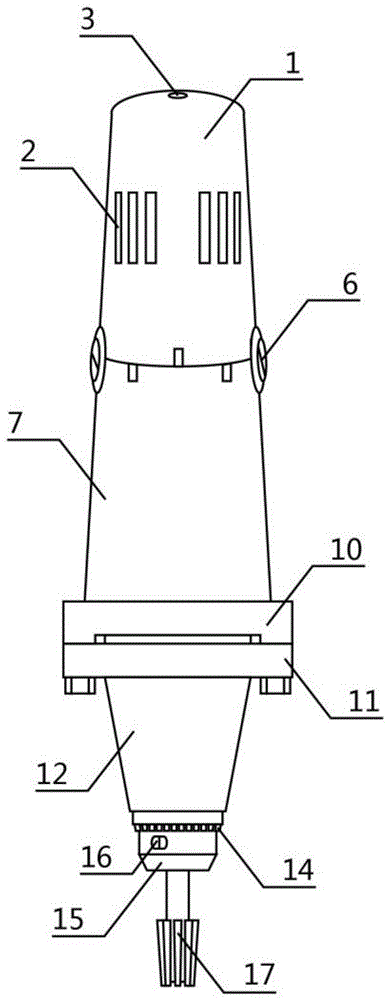

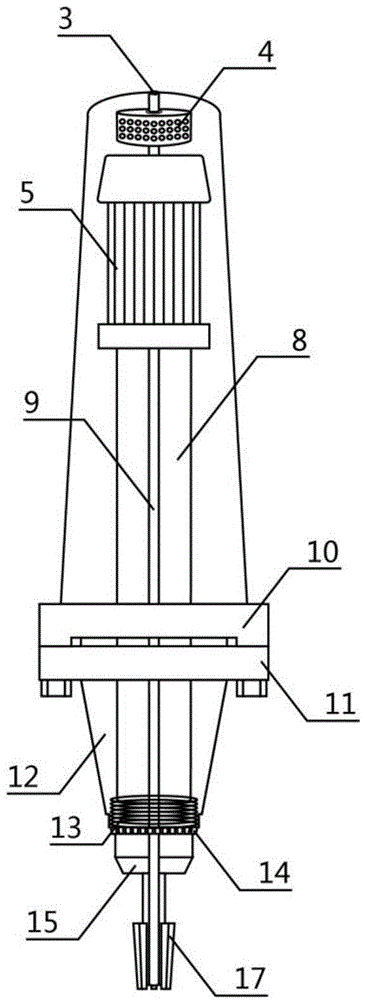

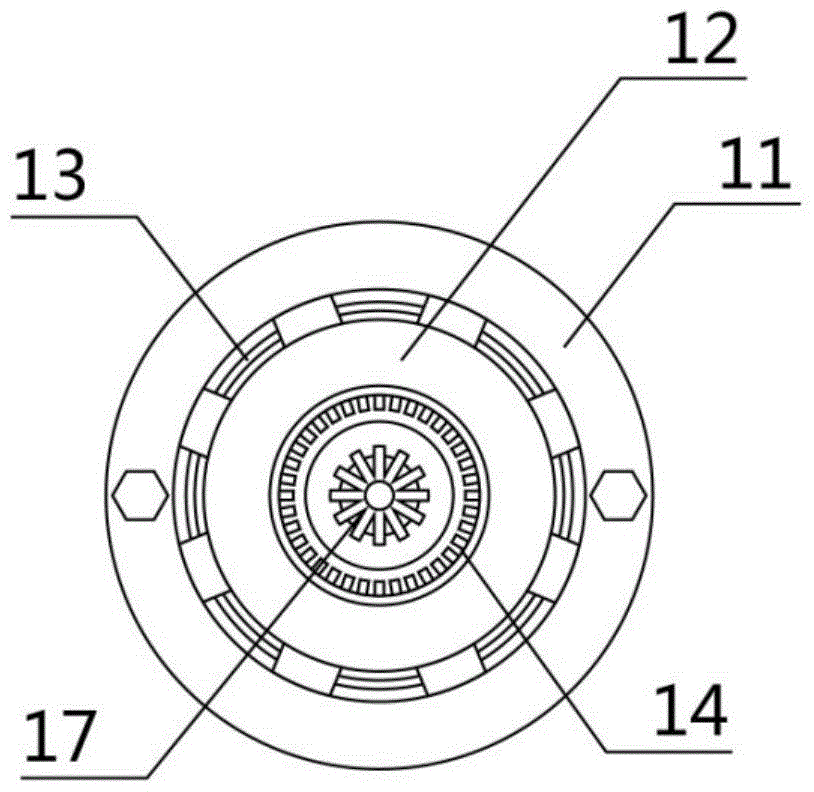

[0024] Such as figure 1 An electric milling head with heat dissipation and cooling holes is shown, which is characterized in that: a gear device buckle cover 1, a middle through buckle cover 7, a middle through blue plate 10, a shock absorbing blue plate 11, a milling head shock absorber 12, The milling head rotating shaft 15 and the milling cutter 17 are composed, and the gear device buckle cover 1 is also provided with a heat dissipation port 2, a central heat dissipation hole 3, a drying device 4, a reduction gear device 5 and several buckles 6, and the heat dissipation The port 2 is located on one side of the gear device cover 1, the heat dissipation port 2 is fixedly connected to the gear device cover 1, and the central cooling hole 3 is located on the top of the gear device cover 1, and the central cooling hole 3 It is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com