Electro-pneumatic braking unit controlled by microcomputer for locomotive braking system

An electro-pneumatic braking and braking system technology, applied in the direction of braking transmission, brakes, braking components, etc., can solve the problems that affect the reliability of train braking, train driving safety, braking system paralysis, and failure to work normally. , to facilitate upgrade and maintenance, reduce failure rate, improve reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

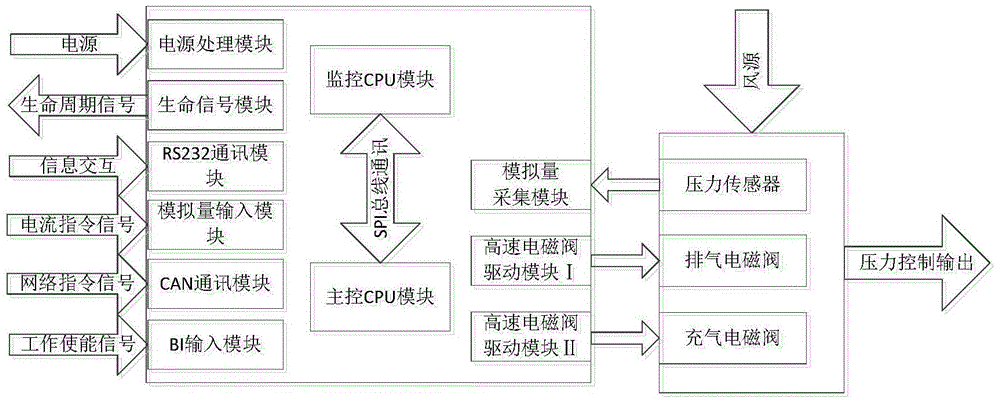

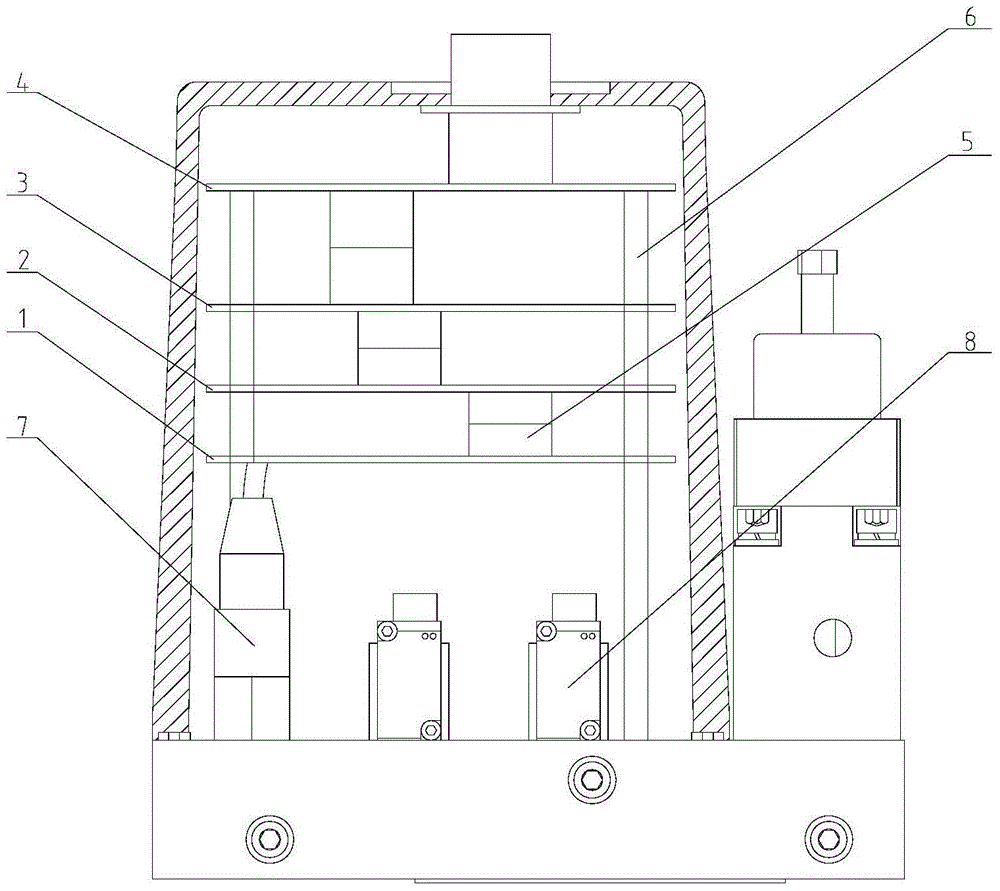

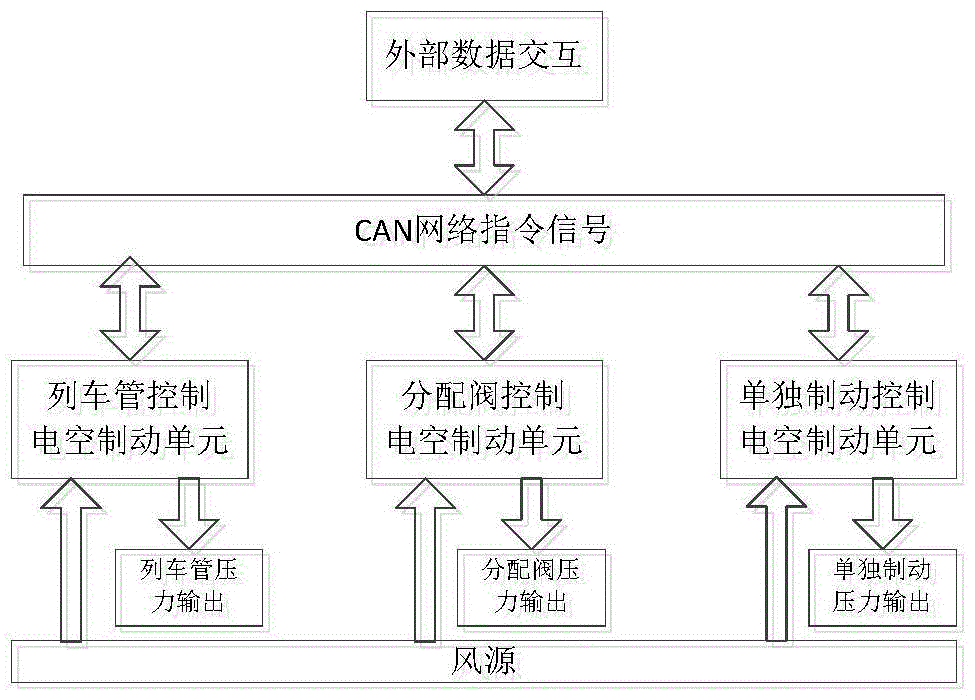

[0037] Such as figure 1 As shown, the present invention discloses a microcomputer-controlled electropneumatic braking unit for locomotive braking systems, which can receive electrical command signals from external systems and complete output control of specified pressures. The electropneumatic braking unit can be applied to trains at the same time Tube control electropneumatic brake unit, distribution valve control electropneumatic brake unit and individual brake control electropneumatic brake unit, the above electropneumatic brake units can independently respond to the control instructions of the brake controller, , Distribution valve and individual brake pressure are controlled.

[0038] The electropneumatic brake unit mainly includes two parts: the air circuit part and the electric part.

[0039] The air circuit part is mainly composed of inflation solenoid valve, exhaust solenoid valve and pressure sensor. Among them, the inflation solenoid valve and the exhaust solenoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com