Jib crane hoisting operation anti-collision method and system

A hoisting operation and crane technology, applied in the field of anti-collision systems, can solve problems such as strong mobility, inapplicability, and complex anti-collision search algorithms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

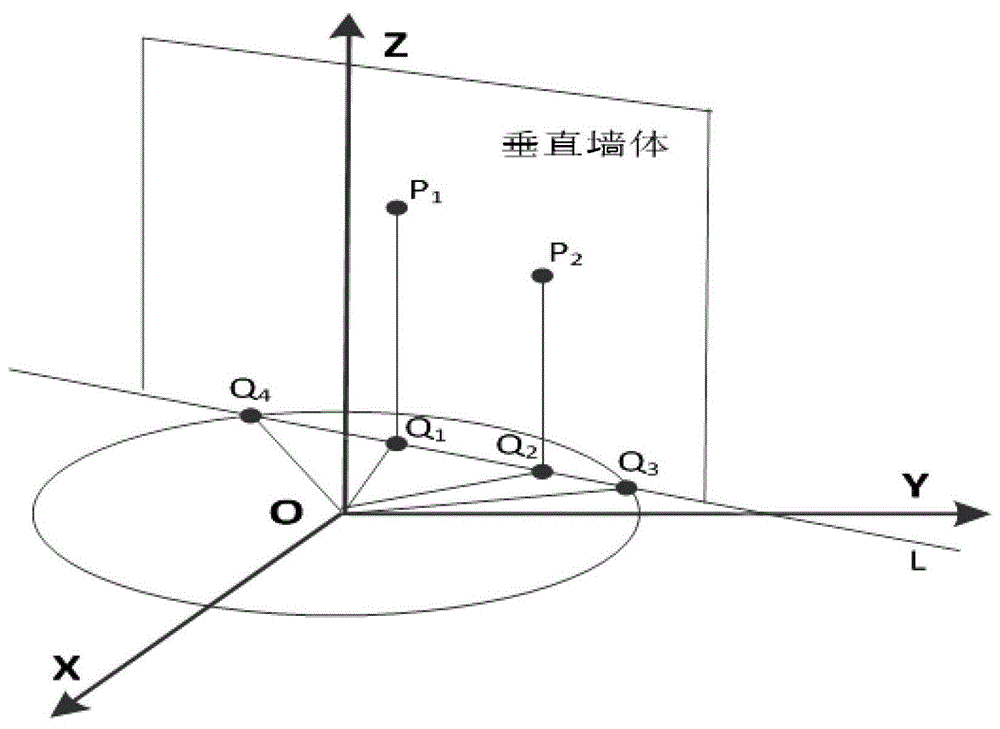

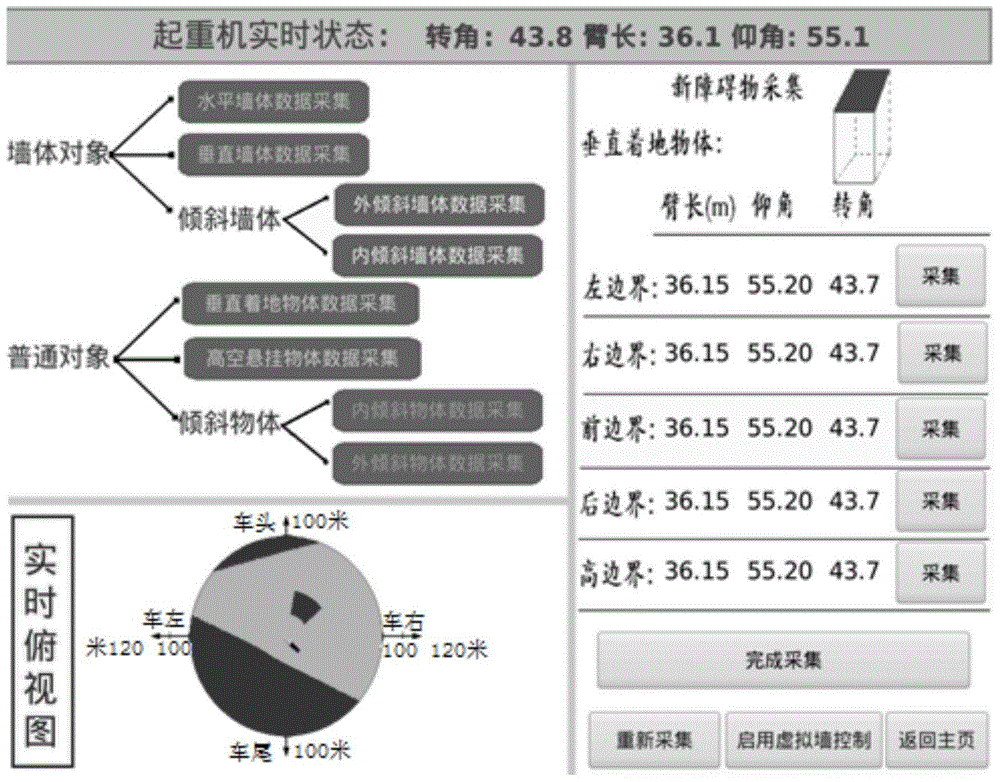

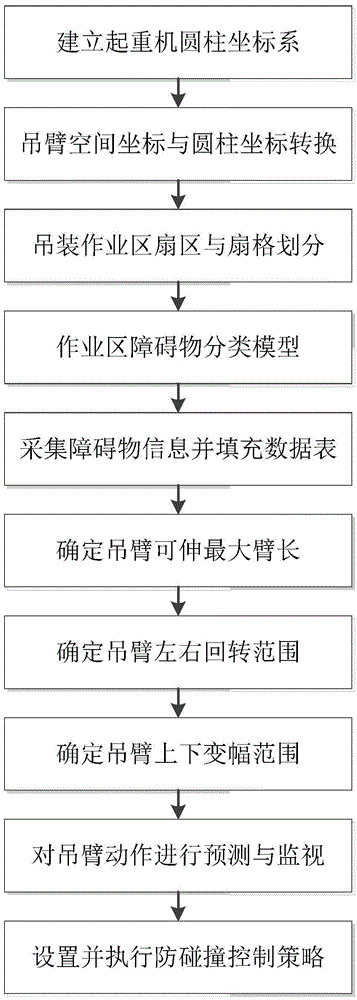

[0058] Comply with the above technical solutions, such as figure 1 As shown, the present invention provides an anti-collision method and system for hoisting a jib crane, providing a complete system and control strategy for the crane hoisting process.

[0059] The main idea of the present invention is to collect and store the obstacle information in the crane operation area through the method of self-learning, and calculate the safe working area in the actual work of the crane on the basis of these data, and then the crane will move in the safe working area. Work quickly and efficiently without concern for collisions.

[0060] 1. Anti-collision method for jib crane hoisting operation

[0061] An anti-collision method for hoisting operation of a jib crane, such as figure 1 shown, including the following steps:

[0062] For the collection of obstacle information in the hoisting operation area, some use infrared range finders, but when the distance is 40 meters outside, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com