A segmented disassembly-free folding rope stop device and a jib system with the rope stop device

A folding and boom technology, applied in the field of boom systems, can solve problems such as difficulty in disassembly and assembly of rope blocks, and achieve the effects of avoiding difficulty in disassembly and assembly, increasing reliability and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing.

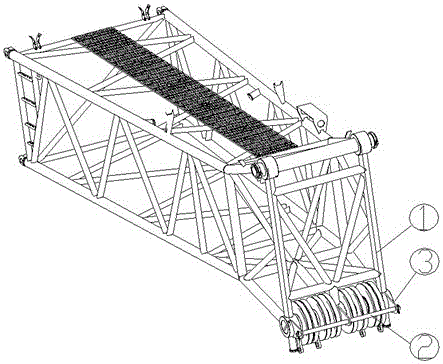

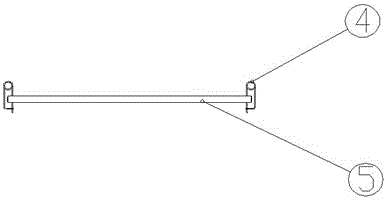

[0042] as attached Figure 5-Figure 9 As shown, this section-free folding rope gear device includes a rope gear frame a, a round roller b, a steel pipe one c, a steel pipe two d and a steel pipe three e with different lengths.

[0043] Such as Figure 8 As shown, the rope rack a is "H type", including horizontal and vertical frames, such as Figure 6 As shown, the front end of the longitudinal frame is provided with hole 1 k1 and hole 2 k2, and the rear end is provided with hole 3 k3, and the rear end is connected through steel pipe 3e.

[0044] Such as Figure 9 As shown, the steel pipe three e is longer, on which the steel pipe two d, the round roller b and the steel pipe one c are installed in sequence, and play the role of installing the round roller b, the steel pipe one c, and the steel pipe two d, and the steel pipe one c, the steel pipe two d according to The po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com