Chemical fuel oil additive and compound fuel oil additive

An additive and composite technology, which is applied in the field of chemical fuel additives and composite fuel additives, can solve the problems of engine performance degradation, increase of combustion chamber deposits, etc., achieve low cost, good safety performance, and improve vehicle power performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

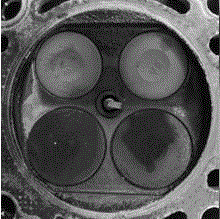

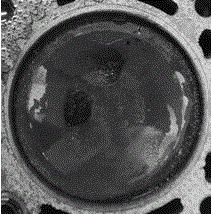

[0089] in, figure 1 , 3 , 5, 7, 9, 11, 13, 15, 17, 19, 21, 23 are the effect diagrams when the composite fuel additive is not added in the embodiment of the present invention.

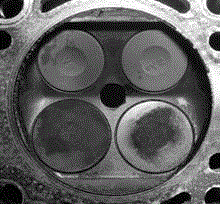

[0090] figure 2 , 4 , 6, 8, 10, 12, 14, 16, 18, 20, 22, 24 are the effect diagrams after adding the composite fuel additive in the embodiment of the present invention and using it for a period of time.

[0091] specifically, figure 1 , 7 , 13, and 19 are respectively the engine cylinder head photos when disassembling and observing for the first time in Embodiments 1 to 4, figure 2 , 8 , 14, and 20 are respectively the engine cylinder head photos when disassembling and observing for the second time in Embodiments 1 to 4; image 3 , 9 , 15, and 21 are respectively the photos of the top of the engine plug when disassembling and observing for the first time in Embodiments 1 to 4, Figure 4 , 10 , 16, and 22 are respectively the photos of the top of the engine plug when disassembling and obser...

Embodiment 1

[0094] A compound fuel additive, which consists of the following components by mass percentage:

[0095] Physical fuel additive 68%; Polyurethane 7%; Polyisobutylamine 12%; Ferrocene 13%. Before using the composite fuel additive, disassemble the engine cylinder head to observe the deposits in the combustion chamber of the vehicle and take pictures, and add the composite fuel additive at a mass ratio of 1:1000 between the composite fuel additive and fuel oil. After driving for 5000km normally, again Disassemble the engine cylinder head sight glass to observe the deposits in the combustion chamber of the vehicle and take pictures.

[0096] Such as Figure 1-6 As shown, by comparing the photos before and after adding the compound fuel additive, it is found that the color of the intake valve becomes lighter, black before adding the additive, and gray after adding the additive; after adding the additive, the carbon deposit on the intake valve begins to crack and fall off (visible t...

Embodiment 2

[0098] A compound fuel additive, which consists of the following components by mass percentage:

[0099] Physical fuel additive 68%; Polyurethane 11%; Polyisobutylamine 7%; Ferrocene 13%; Polyetheramine 1%. Before using the composite fuel additive, disassemble the engine cylinder head to observe the deposits in the combustion chamber of the vehicle and take pictures, and add the composite fuel additive at a mass ratio of 1:500 between the composite fuel additive and fuel oil. After driving for 5000km normally, again Disassemble the engine cylinder head sight glass to observe the deposits in the combustion chamber of the vehicle and take pictures.

[0100] Such as Figure 7-12 As shown, by comparing the photos before and after adding the compound fuel additive, it is found that the color of the intake valve becomes lighter, black before adding the additive, and gray after adding the additive; after adding the additive, the carbon deposit on the intake valve begins to crack and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com