Visual crucible cover for sapphire growth furnace

A technology of growth furnace and crucible cover, which is applied in the field of crystal growth technology and equipment, can solve the problems of temperature gradient and impurity falling into the growth melt that affect the thermal insulation performance of the crucible cover, and achieve cost saving, high melting point and high temperature guarantee environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

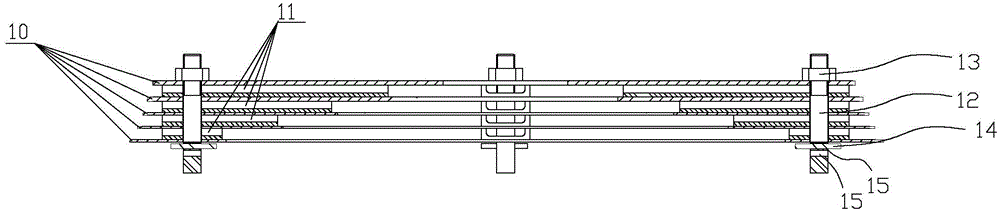

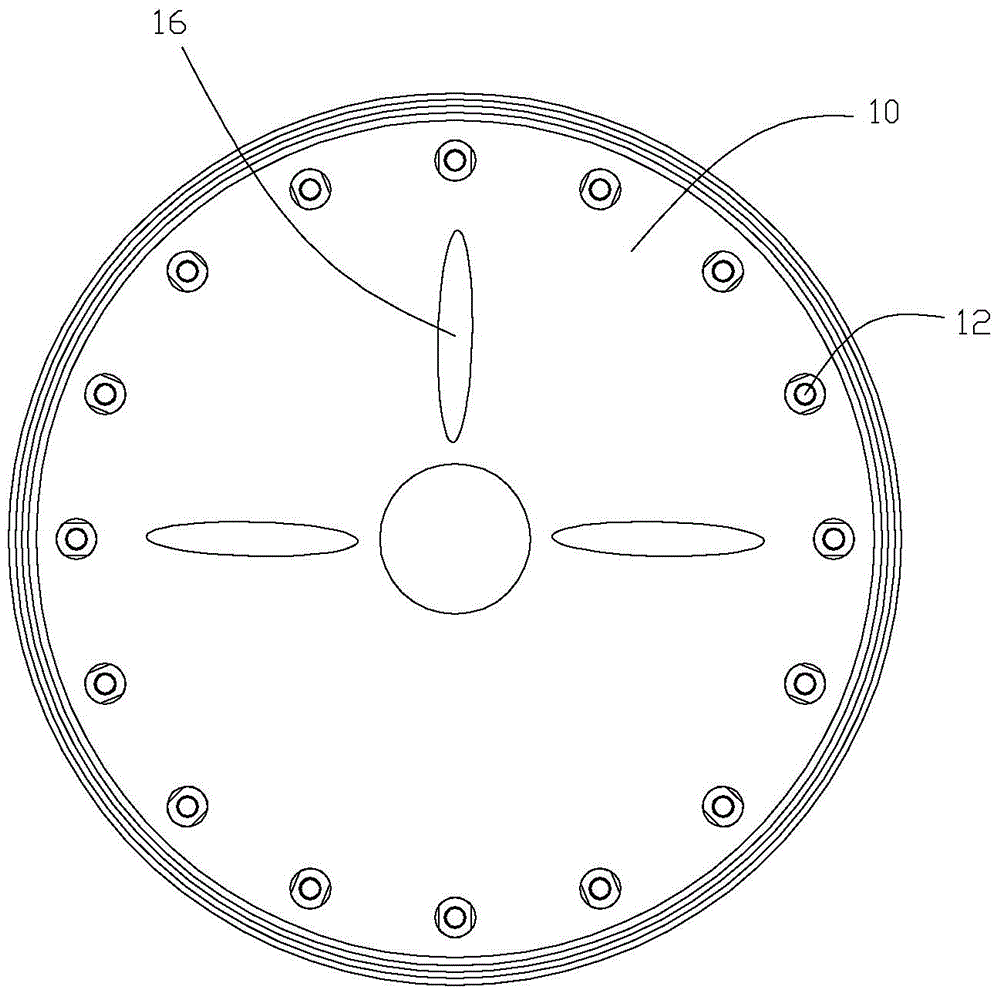

[0026] Such as figure 1 , figure 2 The visible crucible cover for the sapphire growth furnace shown includes several layers of ring plates 10, the ring plates 10 are fixed as a whole through the tungsten screw set, and a U-shaped The spacer 11 ; the ring plate 10 goes up and down, with increasing inner diameter and outer diameter;

[0027] The annular plate 10 includes several layers of annular molybdenum plates or annular tungsten plates, or several layers of annular molybdenum plates and at least one layer of annular tungsten plates, and the annular molybdenum plates are arranged above the annular tungsten plates. The lower layer is a circular tungsten plate and the upper layer is a circular molybdenum plate, and a U-shaped spacer 11 is used between the circular plate 10 and the circular plate 10, which not only saves costs, but also ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com