Device capable of improving quality of ring-spun yarn and application thereof

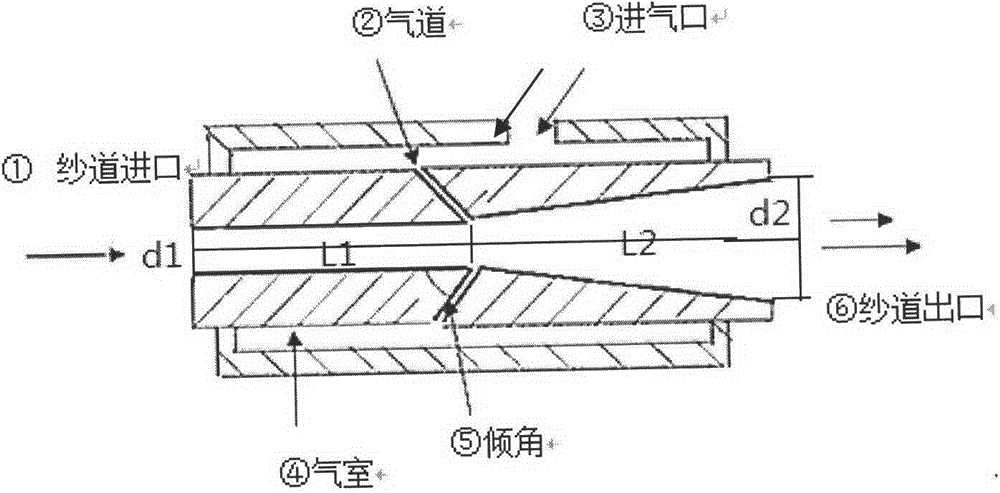

A yarn path and yarn technology is applied in the field of devices for improving yarn quality, which can solve the problems of complex structure of two-stage nozzles, high design cost, large equipment investment, etc., and achieve improved performance, stable yarn quality and stable air pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

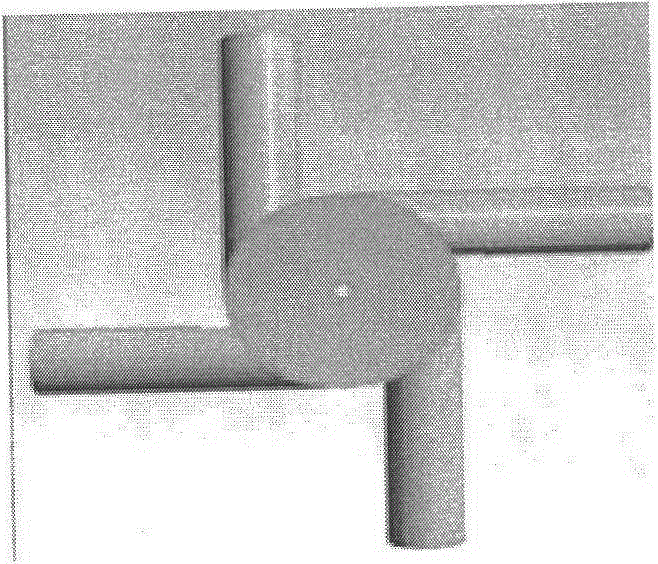

Method used

Image

Examples

Embodiment Construction

[0012] Raw materials: pure cotton yarn with a basis weight of 5.22g / 10m. Spinning machine: CZJF-5 intelligent multifunctional spinning proofing machine. Spinning process conditions: the pressure (gauge pressure) at the inlet of the swirl nozzle is 0.2MPa, the distance from the swirl nozzle to the front jaw is 9cm, and the swirl nozzle is. The Z-twisted pure cotton spun yarn with a twist coefficient of 360 and a fineness of 30tex was spun 1200m for each sample, and the spindle speed was 12000r / min.

[0013] Yarn properties are tested in accordance with the national standard GB / T7243-1987 "Yarn Hairiness Determination Method Projection Counting Method", national standard GB / T3916-1997 "Determination of breaking strength and elongation at break of a single yarn of textile package yarn" , GB / T3292-1997 "Test Method for Uneven Yarn Dryness of Textile Yarns by Capacitance Method". Table 1 Comparison of properties of ordinary ring spun yarns and yarns installed with swirl nozzles. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com