Process for dyeing wool using natural raw materials and use of the wool obtained

A natural raw material, wool technology, applied in the field of dyeing and finishing, can solve the problems of chemical reagents reducing product durability, excessive color difference, unstable quality, etc., achieve low cost, change a single color tone, and enhance the effect of color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

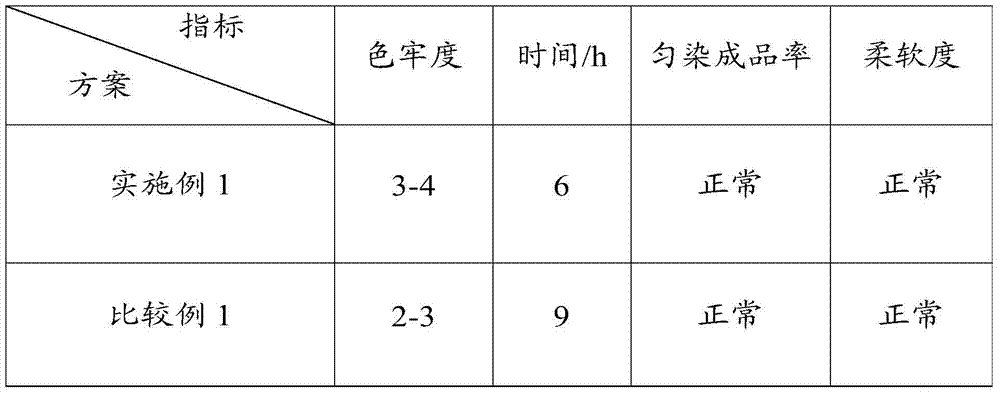

Embodiment 1

[0032] Use pure wool from Nagchu and / or Ngari in Tibet. After selection, the soil and sand in the wool are removed, and then manually torn into fluffy flocs. Then use a wooden spinning wheel or a cross-shaped twisting frame to manually turn and twist it into a woolen yarn with a thickness of 2 mm, and then wind it into a thread ball (the thread ball has a random size and a circumference of 20 cm) for storage. Before dyeing, the thread balls are hand-wound into coils with a diameter of 30 cm, and tied into bundles for dyeing.

[0033] Put 3kg of "indigo" into a dyeing bath filled with 110kg of boiling water (the temperature of boiling water in Lhasa is about 85°C) after crushing and grinding. The dyeing bath equipment is made of pottery or stainless steel. Go to a steering wheel-shaped wheel set in the dye bath equipment, turn it continuously by hand, then add an appropriate amount of 130 grams of dyeing auxiliaries "Jiulu", and dye for 6 hours to get blue. The longer the dyei...

Embodiment 2

[0048] Use pure wool from Nagchu and / or Ngari in Tibet. After selection, the soil and sand in the wool are removed, and then manually torn into fluffy flocs. Then use a wooden spinning wheel or a cross-shaped twisting frame to manually turn and twist the yarn into a woolen yarn with a thickness of 5 mm, and then wind it into a yarn ball with a circumference of 30 cm for storage. Before dyeing, the thread balls are hand-wound into coils with a diameter of 50 cm, and tied into bundles for dyeing.

[0049] Put 6kg of "indigo" into a dyeing bath filled with 130kg of boiling water (the temperature of boiling water in Lhasa is about 85°C) after crushing and grinding. The dyeing bath equipment is made of pottery or stainless steel. Go to a steering wheel-shaped wheel set in the dye bath equipment, rotate it continuously by hand, then add an appropriate amount of 160 grams of dyeing auxiliaries "Jiulu", and dye for 12 hours.

[0050] Take out the dyed wool, soak it in water at 25°C a...

Embodiment 3

[0052] Use pure wool from Nagchu and / or Ngari in Tibet. After selection, the soil and sand in the wool are removed, and then manually torn into fluffy flocs. Then use a wooden spinning wheel or a cross-shaped twisting frame to manually turn and twist the yarn into a woolen yarn with a thickness of 3 mm, and then wind it into a yarn ball with a circumference of 25 cm for storage. Before dyeing, the thread balls are hand-wound into coils with a diameter of 40 cm, and tied into bundles for dyeing.

[0053] Put 5kg of "indigo" into a dyeing bath filled with 120kg of boiling water after crushing and grinding. The dyeing bath equipment is made of pottery or stainless steel, stir evenly, and then put 3.5kg of wool coils to be dyed into a On the wheel in the shape of a steering wheel, turn the wheel continuously, then add an appropriate amount of 150 grams of dyeing auxiliaries "Jiulu", and dye for 9 hours.

[0054] Take out the dyed wool, soak it in water at 30°C and rinse it contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com