Sound absorbing device used for U-beam composite structure of light rail

A technology of sound absorption device and composite structure, applied in the direction of noise absorption device, building, etc., can solve the problems of unstable installation, unsafe, large eccentric distance, etc., and achieve the effect of long service life, low cost and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

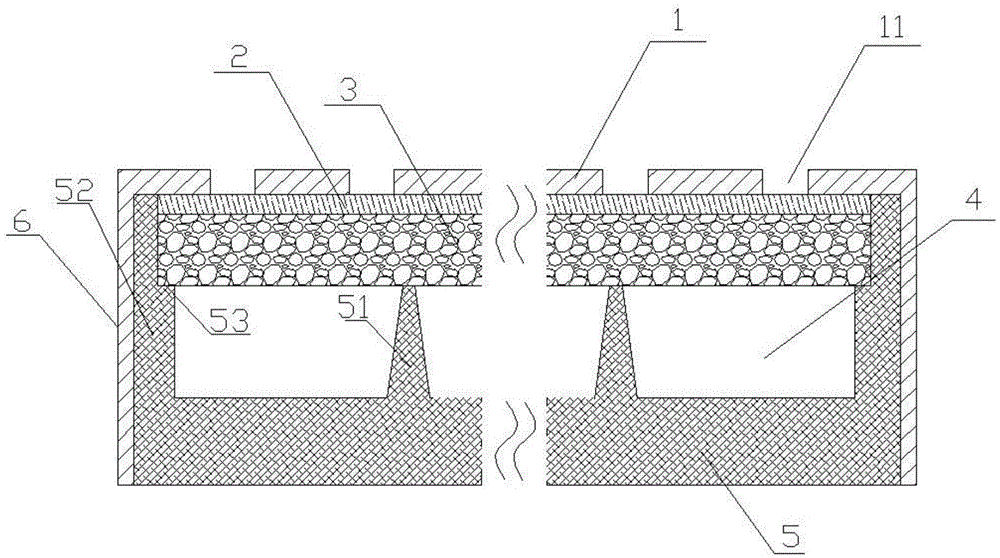

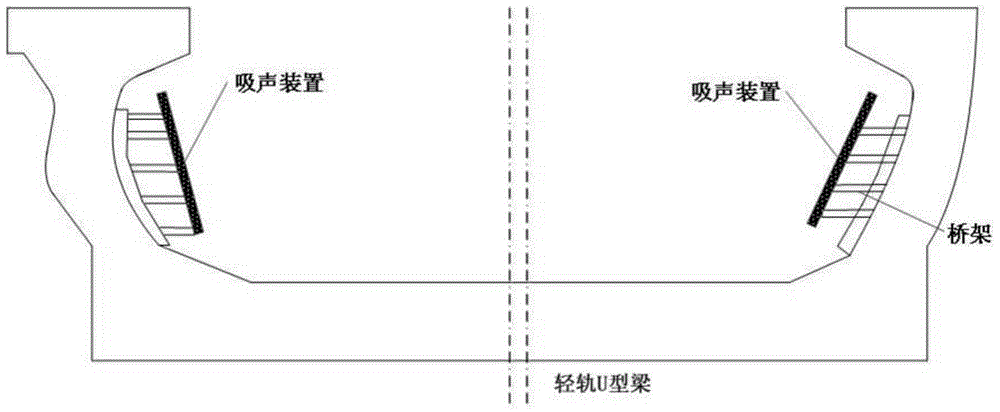

[0018] A sound-absorbing device for light rail U-beam composite structure of the present invention will be described in detail below with reference to the accompanying drawings.

[0019] like figure 1 As shown, it is a sound-absorbing device for light rail U-shaped beam composite structure, including a sound-absorbing device body, and the sound-absorbing device body consists of micro-perforated plate 1, tin foil 2, sound-absorbing cotton 3, and cavity 4 and the bottom plate 5, the surface of the micro-perforated plate 1 is provided with micro-holes 11 at a certain distance, the height of the micro-perforated plate 1 is 1 mm, the diameter of the micro-holes 11 is <1 mm, and the perforation rate is 1% to 5%. The upper part of the sound-absorbing cotton 3 is closely attached to the tin foil 2, and the thickness of the tin foil is 0.1 mm, which can prevent dust and rain. In addition, after applying the tin foil 2 to the sound-absorbing cotton 3, its sound-absorbing performance ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com