Archaized high-gloss strengthened floor board and manufacturing method thereof

A technology for strengthening floors and high-gloss, applied in building structures, floors, buildings, etc., can solve the problems of poor surface flatness of the substrate, insignificant antique effect, visual effect, etc., to achieve improved flatness, good antique effect, pattern consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

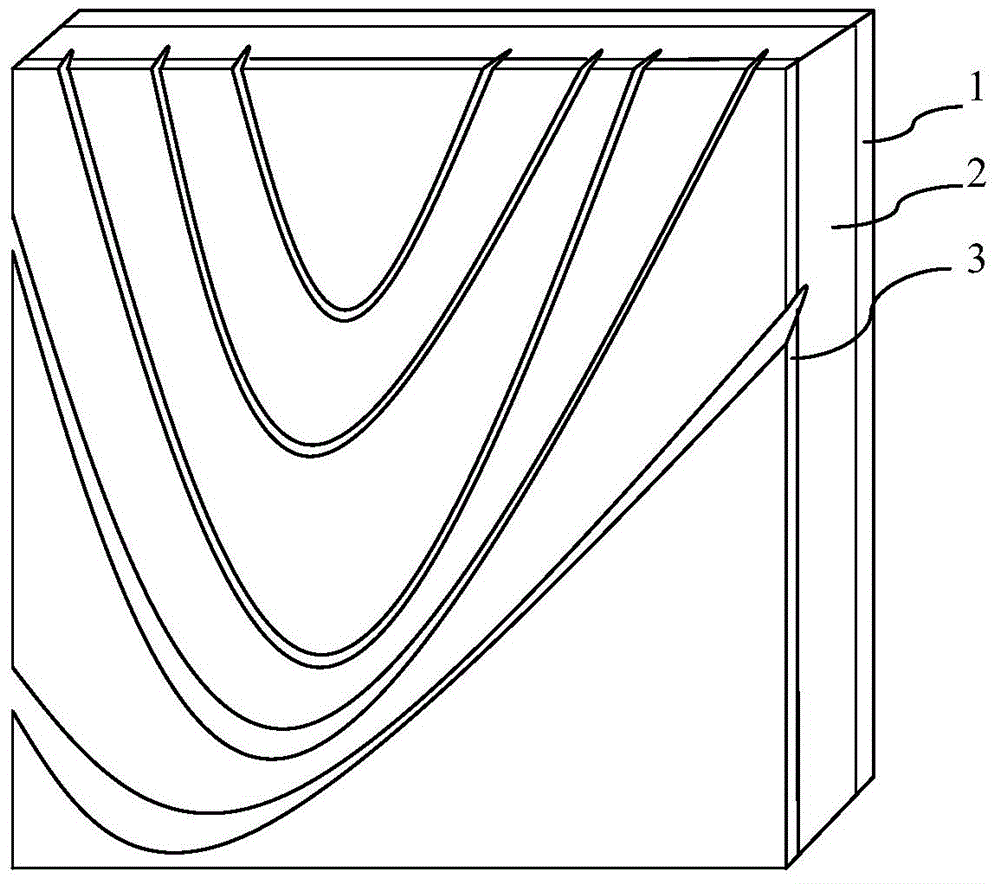

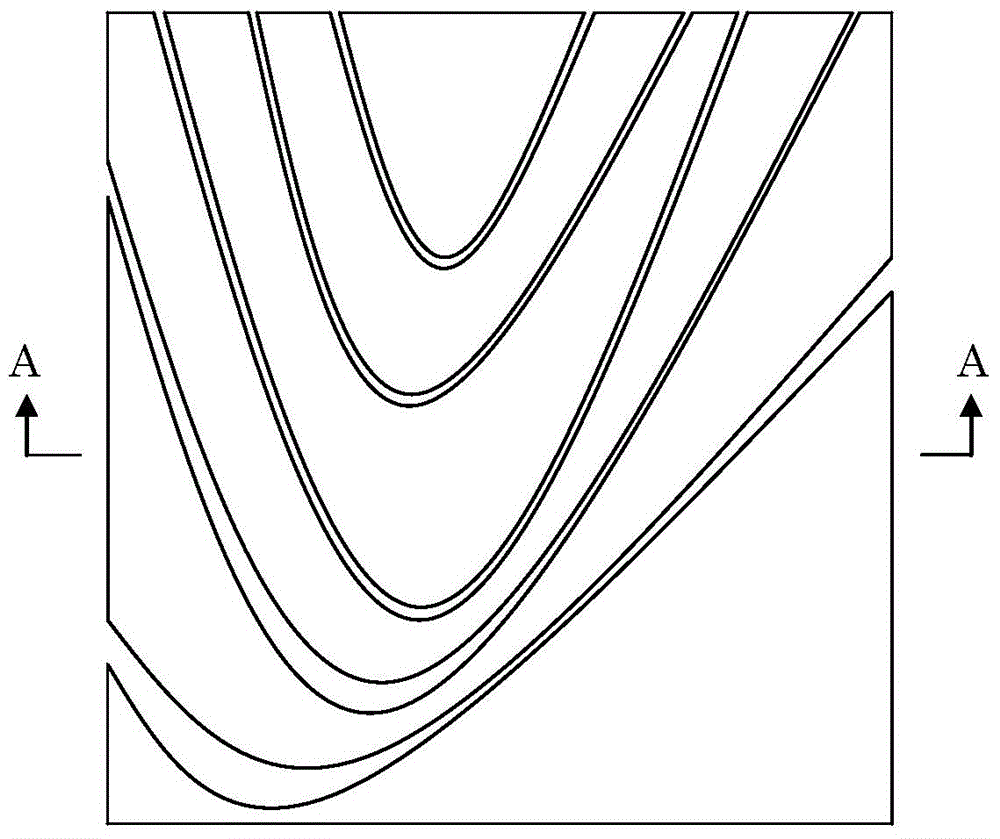

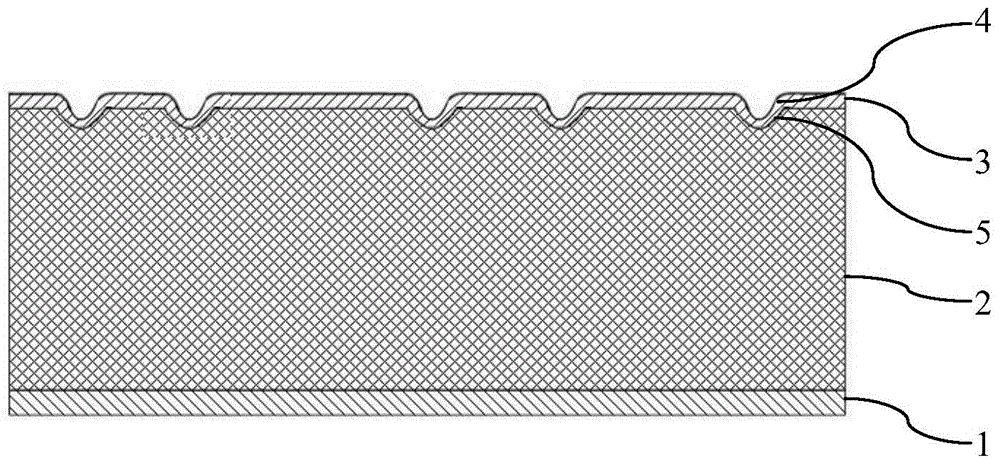

[0030] This embodiment provides an antique high-gloss laminate floor, such as figure 1 , figure 2 as well as figure 2 A section of the floor along the line A-A image 3 As shown in the figure, the floor is composed of a balance layer 1, a base material 2 and a decorative layer 3 whose surface is sprayed with wear-resistant powder in sequence, wherein the upper surface of the base material 2 has a wood grain texture formed by pressing, and the upper surface of the decorative layer 3 has a wood grain texture formed by pressing. The surface has a wood grain texture, and the upper surface of the decorative layer 3 also has an indentation 4 that is consistent with the wood grain texture thereon. The indentations 4 coincide with each other, the depth of the indentation 5 is 0.2 mm, and the depth of the indentation 4 is 0.3 mm. Wherein, the mass percentage of the volatile matter of the decorative layer 3 is 5.5% to 6.0%, the precuring degree is 70% to 75%, the thickness is 0.26m...

Embodiment 2

[0034] This embodiment provides a laminate floor, the structure of which is roughly the same as the floor structure of Embodiment 1, except that the pattern on the upper surface of the decorative layer is a stone texture, the thickness of the decorative layer is 0.31mm, and the density is 0.47g / cm 3 , the surface wear resistance is 7500 rpm. The thickness of the wear-resistant powder sprayed on the decorative layer is 0.1mm, the mass ratio of aluminum oxide and silicon carbide in the wear-resistant powder is 9.5:0.5, the indentation depth on the upper surface of the substrate is 0.25mm, and the indentation on the upper surface of the decorative layer is 0.25mm. The depth is 0.4mm.

[0035] The preparation method of the floor is roughly the same as that in Example 1, the difference is that the predetermined pattern of the working surface of the upper molded steel plate used is consistent with the stone grain texture on the decorative layer, the thickness of the upper molded ste...

Embodiment 3

[0038] This embodiment provides a laminate floor, the structure of which is roughly the same as that of the floor in Embodiment 1, except that the thickness of the decorative layer is 0.28mm and the density is 0.55g / cm 3 , the surface wear resistance is 8000 rpm. The thickness of the wear-resistant powder sprayed on the decorative layer is 0.075mm, the mass ratio of alumina and silicon carbide in the wear-resistant powder is 9.2:0.8, the indentation depth on the upper surface of the substrate is 0.3mm, and the indentation on the upper surface of the decorative layer is 0.3mm. The depth of the marks is 0.5mm.

[0039] The preparation method of the floor is roughly the same as that of Example 1, except that the upper molded steel plate used is 7mm thick, the surface roughness is 0.35, the camber grooves on the working surface are arranged at equal intervals, the groove spacing d is 35mm, and the convex height is 35mm. h is 0.015mm.

[0040] The indentation accuracy of the lami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com