Detachable slewing bearing fixing device of shield heading machine cutter head driving mechanism

A slewing support bearing and cutter head drive technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems that cannot be disassembled, replaced and repaired, shield machines cannot continue to work, and tunnel excavation is at a standstill.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

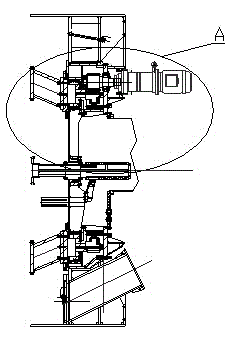

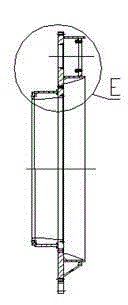

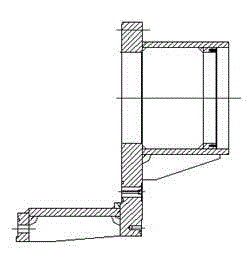

[0024] like Figure 1 to Figure 11 As shown in the figure, a detachable slewing support bearing fixing device for the cutter head drive mechanism of a shield tunneling machine includes a cutter head end face seal assembly 1, a transmission ring 2, a cutter head radial seal assembly 3, a center bin 4, and a center bin screw hole 5. Power box seat bolt 6, transmission pinion positioning bearing 7, power box seat 8, transmission pinion 9, connecting bolt 10 between the center compartment and the power box cover, connecting bolt 11 between the power box cover and the power box seat, power transmission ring and Slewing bearing connecting bolt 12, slewing support bearing 13, power box cover 14, slewing support bearing and power box cover connecting bolt 15, motor and deceleration mechanism 16, cutter head drive mechanism sealing assembly, cutter head drive me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com