Drilling rig drilling buffer device

A buffer device and drilling rig technology, applied in the direction of mechanical equipment, spring/shock absorber design features, shock absorbers, etc., can solve the problems of increased drilling tool quality, high replacement costs, unfavorable use and promotion, etc., to improve service life, Effect of improving shock absorption performance and improving mechanical wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

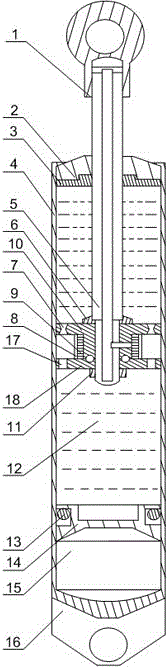

[0022] Such as figure 1As shown, this embodiment includes a working cylinder 4 with both ends sealed and a piston rod 5 that penetrates through the end cover 2 of the working cylinder 4 and its end is placed in the working cylinder 4. A longitudinal The cross-section is a "T" type piston 10, two semicircular baffles 18 are hinged at the end of the vertical part of the piston 10, and a gasket 6 is installed on the upper end of the piston 10, and a ring for fixing the piston 10 and The nut 11 of the baffle plate 18 has a plurality of upper discharge holes 7 on the horizontal part of the piston 10, and has a plurality of lower discharge holes 17 corresponding to the upper discharge holes 7 on the two baffle plates 18. The aperture of the upper discharge hole 7 increases from the middle to both ends. A coil 9 is arranged in the middle of the piston 10, and an isolation ring 8 is arranged on the outer wall of the coil 9. The inside of the piston rod 5 is hollow, and the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com