Tangential modified gear

A technology of shifting gears and gears, which is applied to belts/chains/gears, components with teeth, portable lifting devices, etc. The effect of avoiding excessive noise band width and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

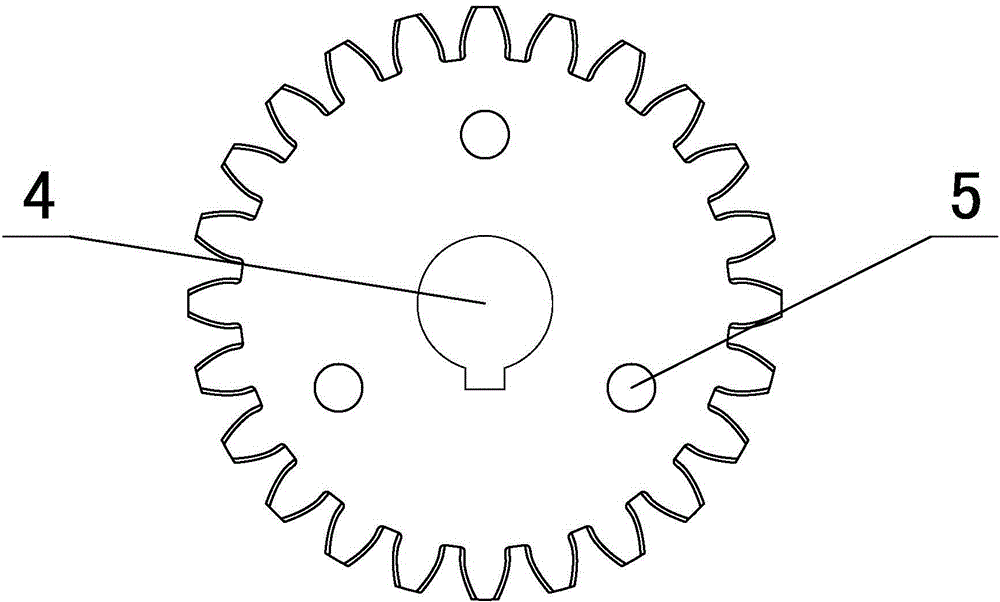

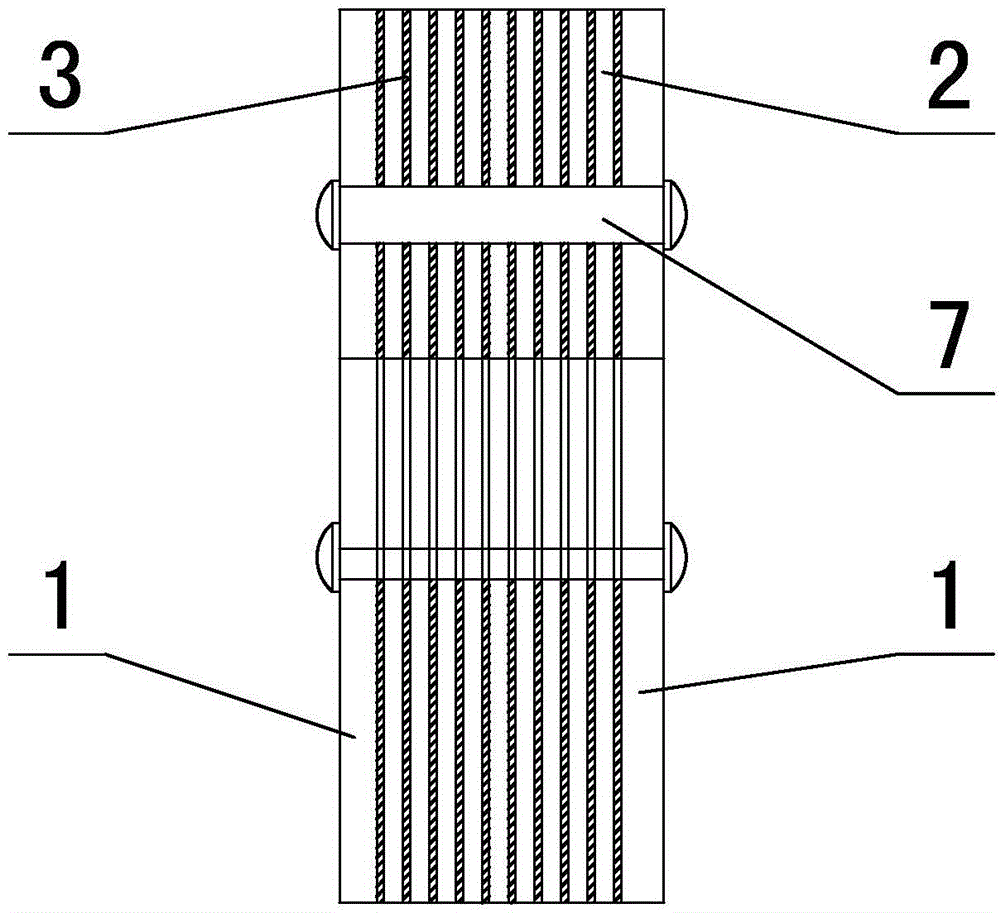

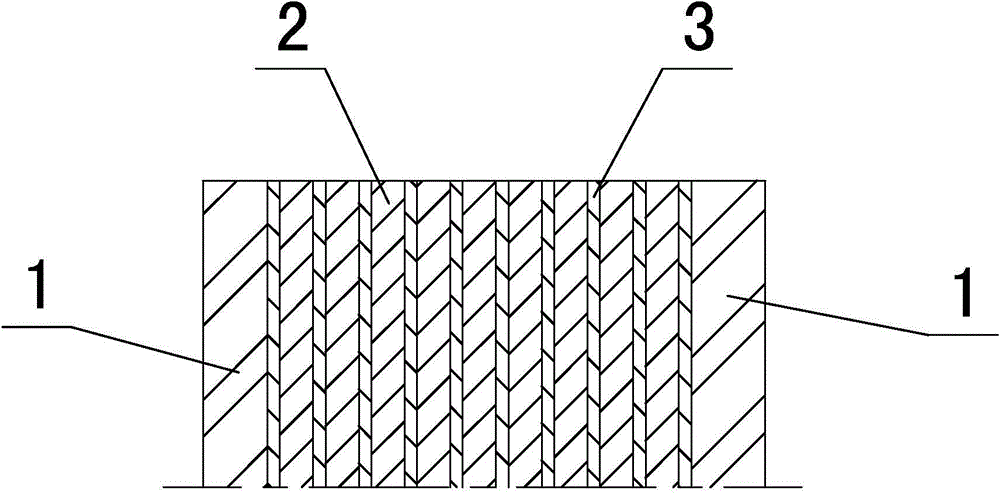

[0028] exist figure 1 figure 2 In the shown embodiment 1, a tangential displacement gear is composed of 11 gears with the same number of teeth and thickened tooth shapes, which are sequentially stacked. The outer gear 1 at the end and the 9 inner gears 2 between the two outer gears (see image 3 ), the thickness of all the inner gears is equal, the thickness of the outer gears is 4 times the thickness of the inner gears, and the vibration and noise reduction plates 3 are embedded between the adjacent gears, the basic structure of the vibration and noise reduction plates It is compatible with the tooth plate, and the thickness of all the vibration and noise reduction plates is equal and glued to the adjacent tooth plate. The thickness of the vibration and noise reduction plate is 30% of the thickness of the internal tooth plate. Shaft hole 4, around the shaft hole is provided with a number of fixing holes 5 for fixing the tooth piece, the diameter of the addendum circle and ...

Embodiment 2

[0030] The gear in Example 2 is a helical gear, and the thickness of the 7 internal tooth plates in the gear is equal, and the 8 vibration and noise reduction plates are glued to the adjacent tooth plates. The thickness of the vibration and noise reduction sheet is greater than the thickness of the vibration and noise reduction sheet on the side of the inner gear with a smaller tooth thickness. The thickness of the vibration and noise reduction sheet changes linearly along the gear axis. The minimum thickness of the vibration and noise reduction sheet It is 15% of the thickness of the inner gear, the maximum thickness of the vibration and noise reduction plate is 30% of the thickness of the inner gear, the thickness of the outer gear is equal and its thickness is 3 times the thickness of the inner gear, and the rest are the same as in Example 1 .

Embodiment 3

[0032] In embodiment 3, the gear includes 8 internal tooth plates and 9 vibration-damping and noise-reducing plates. The internal tooth plates have different thicknesses, and the thickness of the internal tooth plate with smaller tooth thickness is greater than that of the internal tooth plate with larger tooth thickness. Thickness, the thickness of the maximum thickness internal gear is 1.8 times the thickness of the minimum thickness internal gear, the thickness of the internal gear changes linearly along the gear axis, and the thickness of all vibration and noise reduction plates is equal and the same as that of the adjacent gear Bonding, the thickness of the vibration and noise reduction sheet is 18% of the thickness of the largest internal tooth sheet, the thickness of the external tooth sheet is equal and its thickness is 2.5 times the thickness of the largest internal tooth sheet, and the rest are the same as in embodiment 1 or embodiment 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com