Visual experiment device suitable for low-temperature gas-liquid two-phase mixing

A test device, gas-liquid technology, applied in the field of low-temperature gas-liquid two-phase mixing visual test device, to achieve the effects of easy disassembly, reduced installation difficulty, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

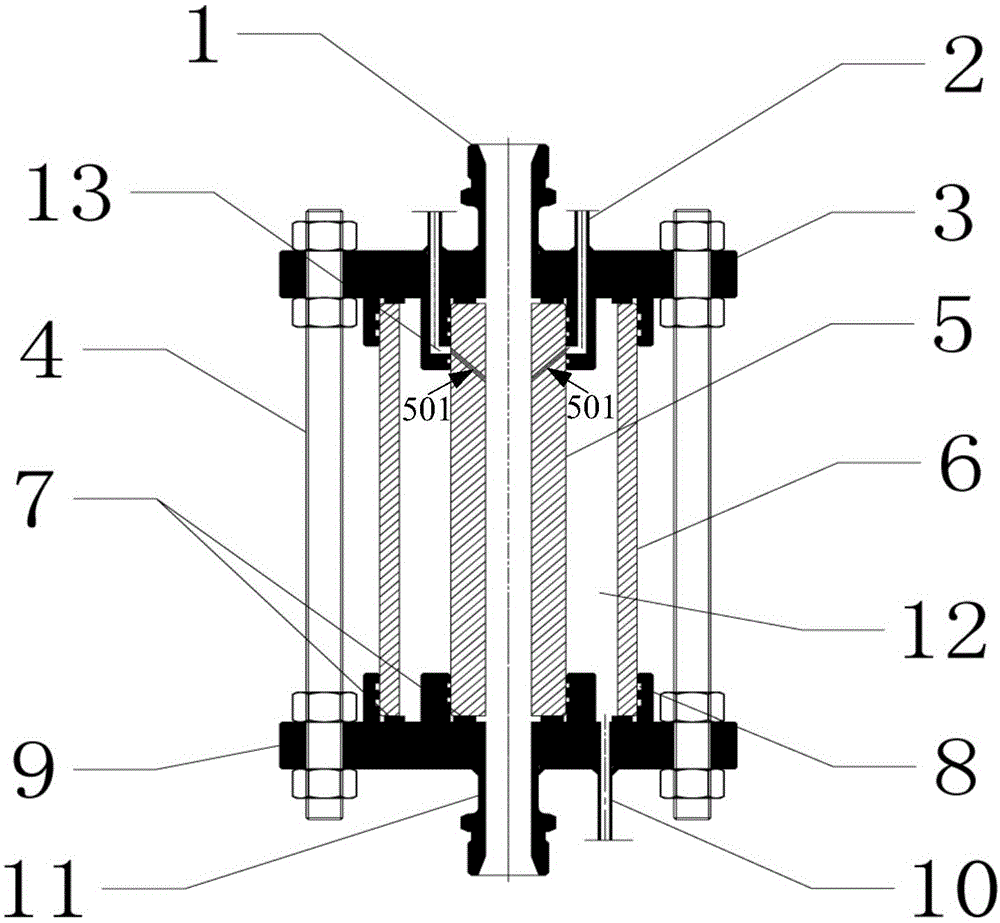

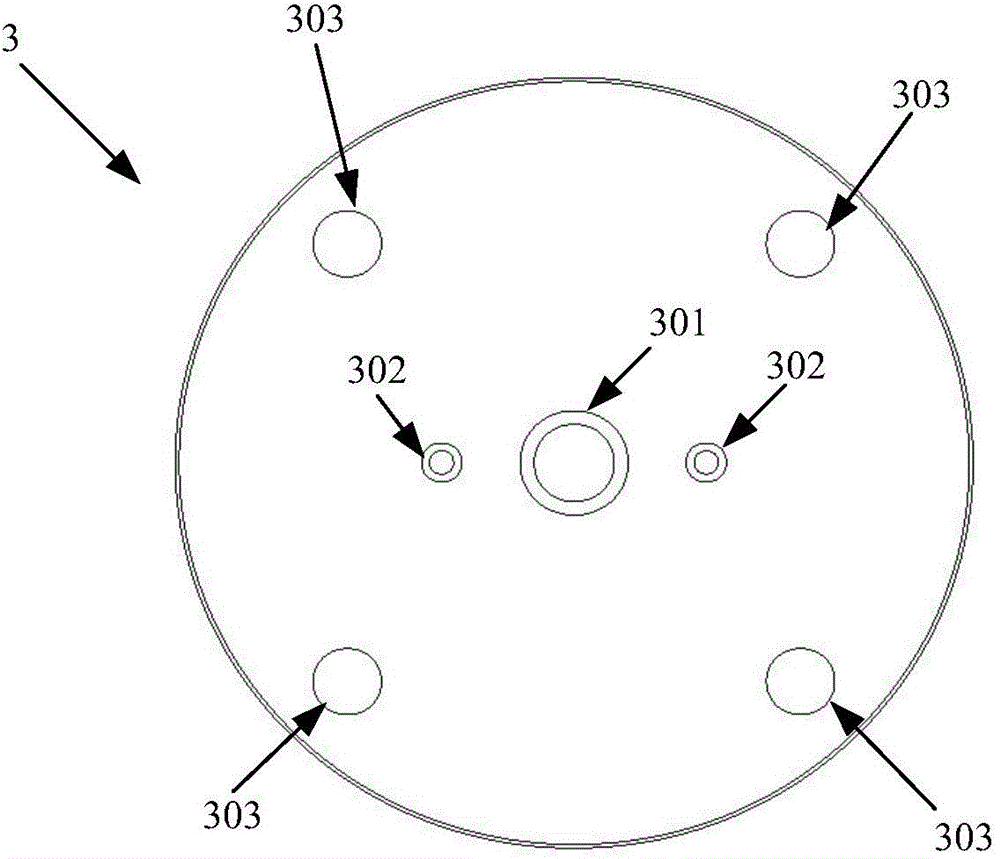

[0028] The invention provides a visual test device suitable for low-temperature gas-liquid two-phase mixing. The low temperature generally refers to low-temperature liquids with a temperature range from 20K to 90K, such as liquid oxygen, liquid nitrogen, and liquid hydrogen. The visualization test device such as figure 1 As shown, it mainly includes upper nozzle 1, lower nozzle 11, gas inlet pipe 2, upper sealing flange tooling 3, lower sealing flange tooling 9, connecting screw 4, inner glass tube 5, outer glass tube 6 And the vacuum tube 10 also includes a sealing gasket 7 and a sealing ring 8.

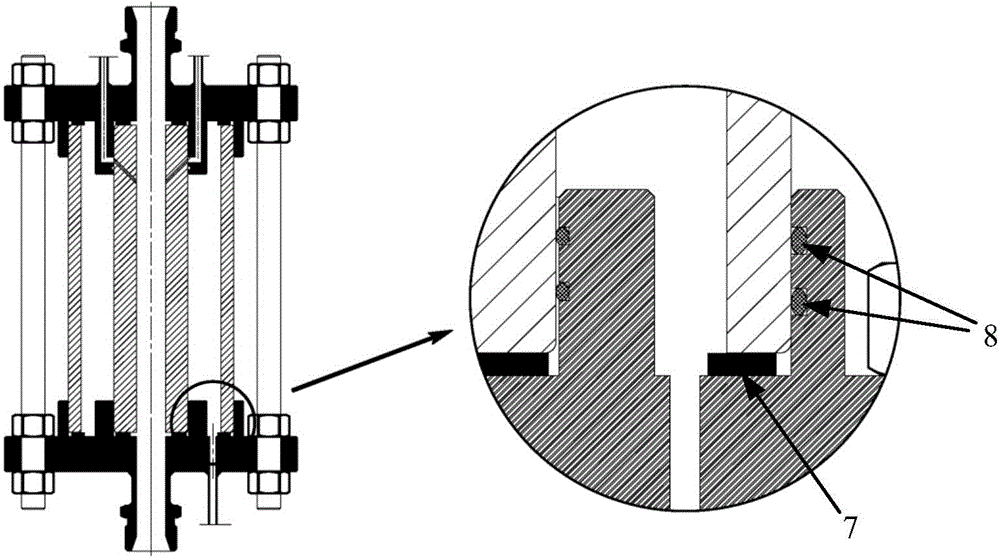

[0029] The inner glass tube 5 and the outer glass tube 6 are connected to the upper sealing flange tooling 3 and the lower sealing flange tooling 9 through radial sealing, and the radial sealing position is sealed by a sealing ring 8, like Figure 1A . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com