Reliability design method for upper crossbeam of high-speed pressure machine

A design method and reliability technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as calculation errors of probability model parameter structure reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with drawings and embodiments.

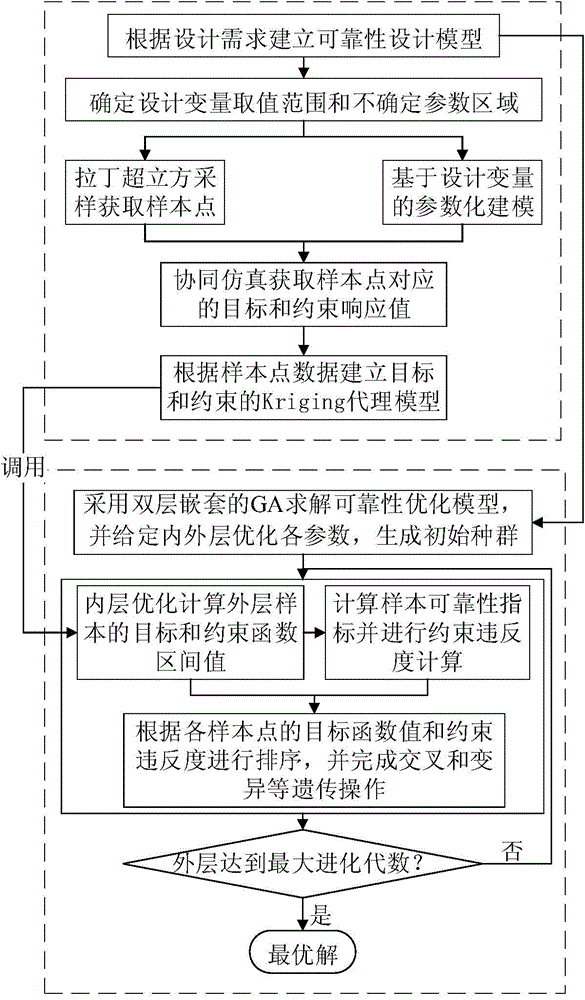

[0058] Such as figure 1 Shown, the present invention a kind of high-speed press upper beam reliability design method, comprises the following steps:

[0059] (1) Establish a reliability design model for the upper beam of a high-speed press that describes uncertain factors in intervals:

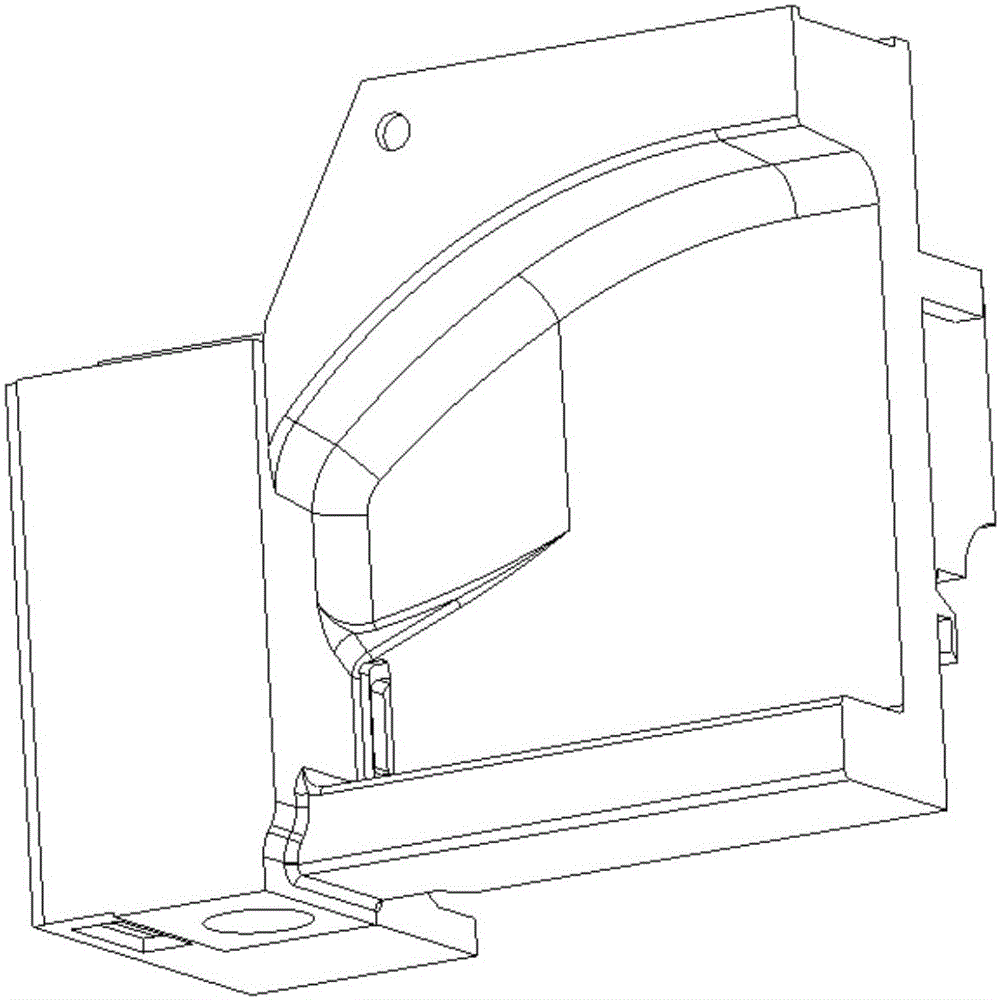

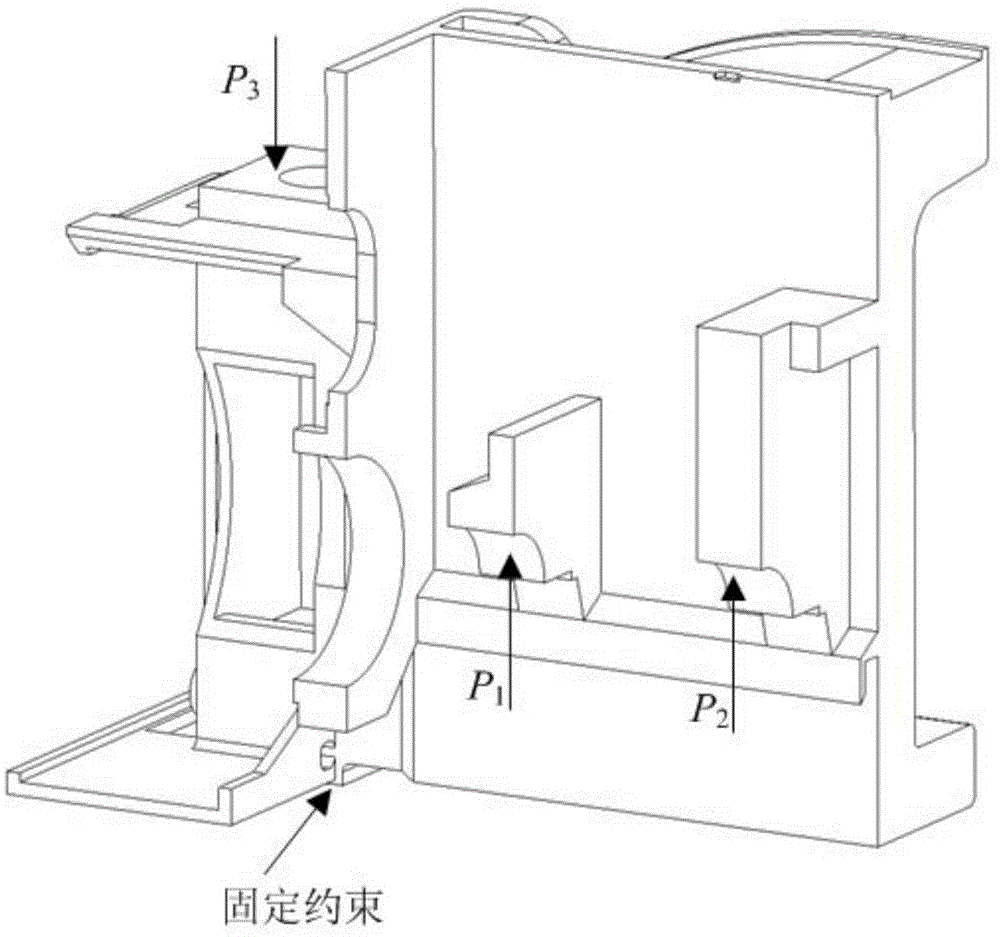

[0060] Select the upper beam of a certain type of high-speed press as the research object, such as figure 2 Shown as its 1 / 4 model, according to the actual design requirements, to Figure 4 The cross-sectional dimension h of the upper and middle beams 1 、h 2 , l 1 , l 2 and l 3 Design variables for the size, with image 3 The external force P shown 1 ,P 2 ,P 3 The density ρ is the uncertainty factor described in the interval, and the deformation is the optimization design goal. The maximum allowable stress of the upper beam is [60,61] MPa, and the reliability requirement is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com