Nipple sealing agent for preventing mastitis of cows in dry period and preparation method thereof

A teat sealant and a technology for dry milk period, applied in the field of a teat sealant for preventing dry milk cow mastitis and its preparation field, can solve the problems of breast fever and pain, increase in milk somatic cells, and the cure rate, so as to improve the cure rate, Good therapeutic effect, relieve inflammation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

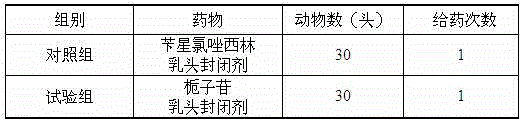

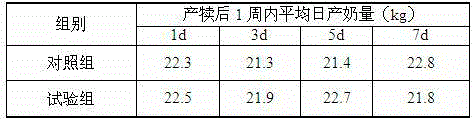

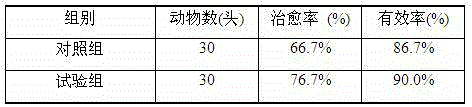

Method used

Image

Examples

Embodiment 1

[0025] 1) Micronize bismuth subnitrate and geniposide separately, until the particle size is not greater than 25 microns (μm);

[0026] 2) Put 26.43g of liquid paraffin into a 250ml beaker, raise the temperature to 140°C, add 2.5g of aluminum stearate, 1.0g of silicon dioxide, 0.05g of 2,6-di-tert-butyl-p-cresol, and o-phenyl Phenol 0.02g, heated and stirred until completely dissolved to make it into a gel matrix, and cooled in a cold water bath to below 40°C;

[0027] 3) Take 5.0 g of the geniposide treated with micronization in step 1) and place it in the gel matrix, disperse it by ultrasonic, and homogenize it in a high-shear dispersing homogenizer for 10 minutes;

[0028] 4) Add 20.0g bismuth subnitrate in batches, add 2.0g in each batch, stir while adding, continue stirring for 20min after adding the 20.0g bismuth subnitrate; then add 45.0g bismuth subnitrate in batches, each time Add 2.0g, stir while adding, and continue stirring for 20 minutes after the addition is com...

Embodiment 2

[0031] 1) Micronize bismuth subnitrate and geniposide separately, until the particle size is not greater than 25 microns (μm);

[0032] 2) Put 39.93g of liquid paraffin into a 250ml beaker, raise the temperature to 140°C, add 4.0g of aluminum stearate, 1.0g of silicon dioxide, 0.05g of 2,6-di-tert-butyl-p-cresol, and o-phenyl Phenol 0.02g, heated and stirred until completely dissolved to make it into a gel matrix, and cooled in a cold water bath to below 40°C;

[0033] 3) Take 5.0 g of the geniposide treated with micronization in step 1) and place it in the gel matrix, disperse it by ultrasonic, and homogenize it in a high-shear dispersing homogenizer for 10 minutes;

[0034] 4) Add 15.0g bismuth subnitrate in batches, add 1.5g in each batch, stir while adding, continue stirring for 20min after adding the 15.0g bismuth subnitrate; then add 35.0g bismuth subnitrate in batches, each time Add 2.0g, stir while adding, and continue stirring for 20 minutes after the addition is com...

Embodiment 3

[0037] 1) Micronize bismuth subnitrate and geniposide separately, until the particle size is not greater than 25 microns (μm);

[0038] 2) Put 17.43g of liquid paraffin into a 250ml beaker, raise the temperature to 140°C, add 1.5g of aluminum stearate, 1.0g of silicon dioxide, 0.05g of 2,6-di-tert-butyl-p-cresol, and o-phenyl Phenol 0.02g, heated and stirred until completely dissolved to make it into a gel matrix, and cooled in a cold water bath to below 40°C;

[0039] 3) Take 5.0 g of the geniposide treated with micronization in step 1) and place it in the gel matrix, disperse it by ultrasonic, and homogenize it in a high-shear dispersing homogenizer for 10 minutes;

[0040] 4) Add 25.0g bismuth subnitrate in batches, add 2.5g in each batch, stir while adding, continue stirring for 20min after adding the 25.0g bismuth subnitrate; then add 50.0g bismuth subnitrate in batches, each time Add 2.5g, stir while adding, and keep stirring for 20 minutes after the addition is complet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com