Micro-feeding device for hydraulic boring tool and boring lathe with micro-feeding device

A hydraulic and knife device technology, which is applied in the direction of feeding device, automatic control device, boring machine/drilling machine parts, etc., can solve the problems of limited precision, poor knife-engaging rigidity, and many transmission links, so as to improve control accuracy, The effect of high precision and simplified mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

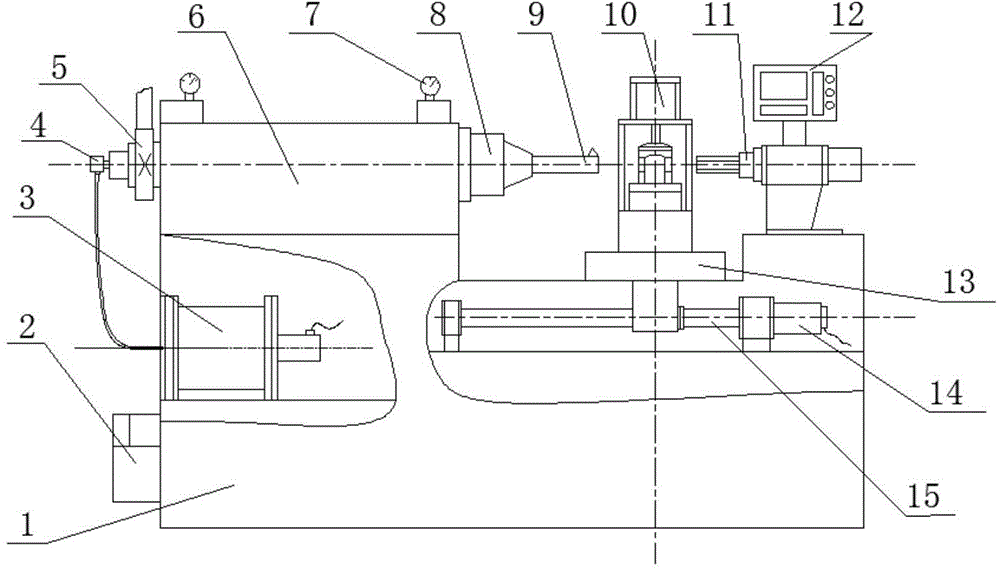

[0030] A new type of boring machine, its structure includes: machine bed 1, automatic lubrication device 2, tool compensation drive device 3, rotary joint 4, belt pulley 5, precision hydrostatic boring head 6, pressure gauge 7, elastic deformation device 8, knife Rod 9, workpiece clamping mechanism 10, workpiece positioning mechanism 11, numerical control device 12, longitudinal moving slide table 13 adopting linear guide rail, longitudinal servo drive motor 14;

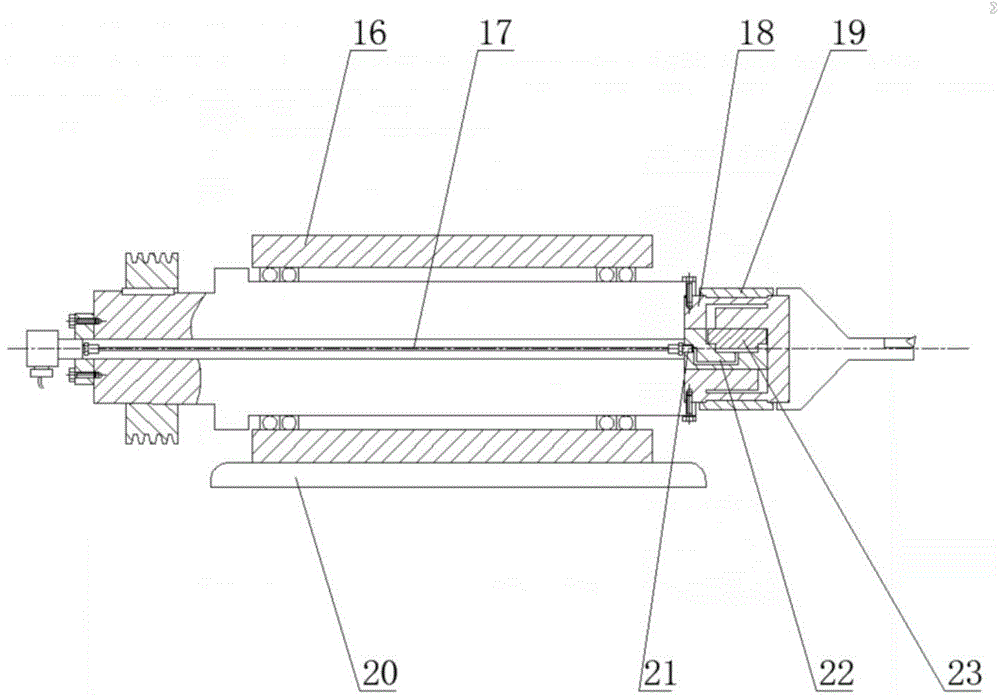

[0031]The spindle system includes: a spindle box 16, a pressure oil pipe 17, a spindle base 20, and an elastic deformation body 18; the spindle box is installed on a spindle base, and a pressure oil pipe connected to a hydraulic oil chamber is arranged in the spindle box. The other end of the oil pipe communicates with the oil cavity in the elastic deformation body, and the elastic deformation body drives the movement of the knife rod.

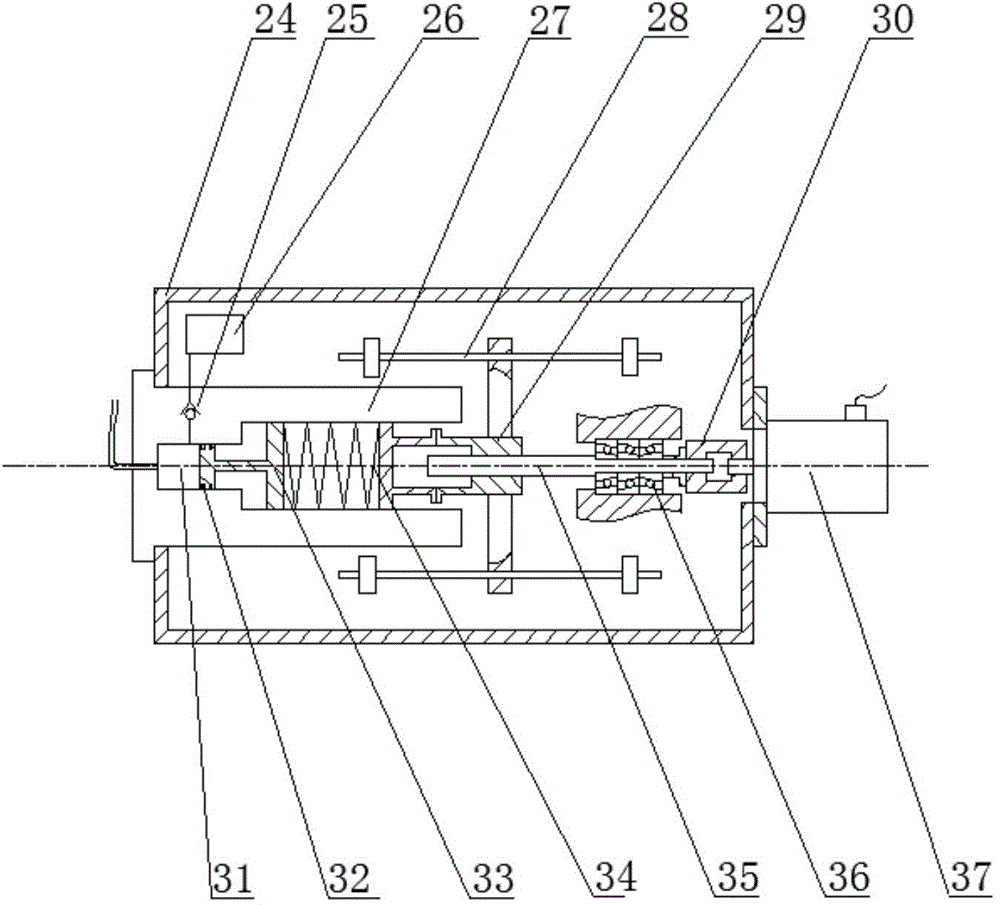

[0032] The elastic deformation body 18 includes a power unit fixed part 22, a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com