Tube body perforating tooling

A cylinder and tooling technology, applied in auxiliary devices, manufacturing tools, metal processing, etc., can solve the problems of high round-trip cost, large investment, damage to the cylinder, etc., and achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

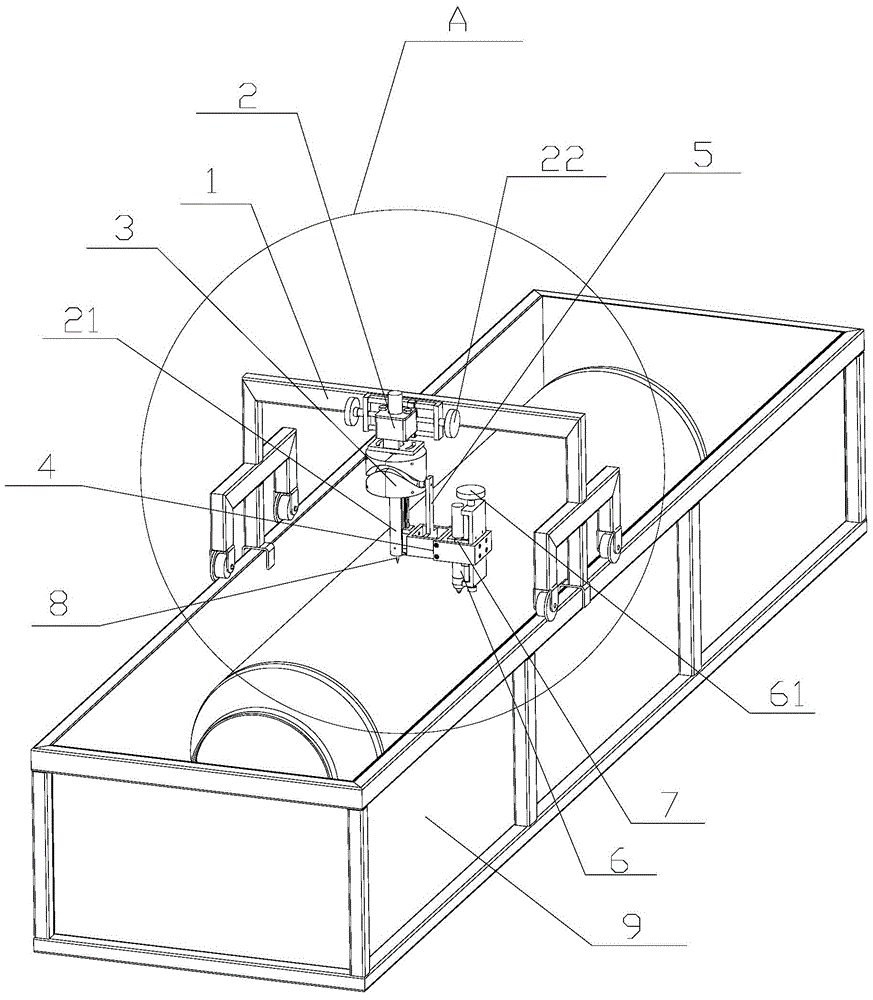

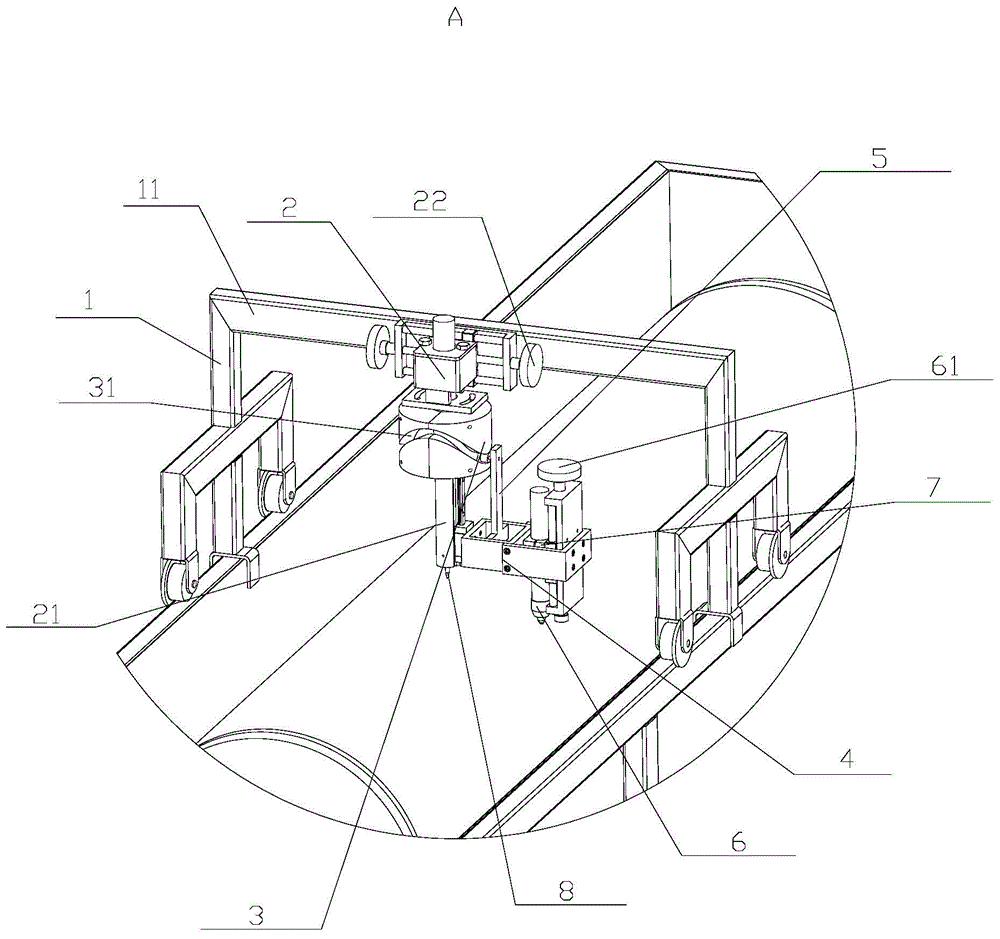

[0016] Such as figure 2 As shown, a cylinder opening tool is suitable for drilling holes on the surface of the cylinder, including a gantry 1, a centering cutting device 2 is provided on the beam 11 of the gantry 1, and the centering cutting device 2 includes a centering Column 21, a cylindrical cam 3 is installed on the top of the centering column 21, and the cylindrical cam 3 is provided with a curved groove 31. The bottom of the cylindrical cam 3 and one side of the centering column 21 are provided with a lifting and rotating motion along the centering column 21. Cutting head 4, cutting head 4 comprises guide rod 5 and mounting base 7 of cutting torch 6, the distance from the muzzle of cutting torch 6 to the center line of centering column 21 is consis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap