A combined twin-shaft continuous mixer

A twin-horizontal shaft, combined technology, used in cement mixing devices, raw material supply devices for sale, clay preparation devices, etc., can solve problems such as the deterioration of the stiffness of the mixing shaft, the reduction of the reliability of the machine, the reduction of the residence time of the stirring speed, and the increase of the The effect of stirring time, eliminating stirring dead zone and improving stirring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

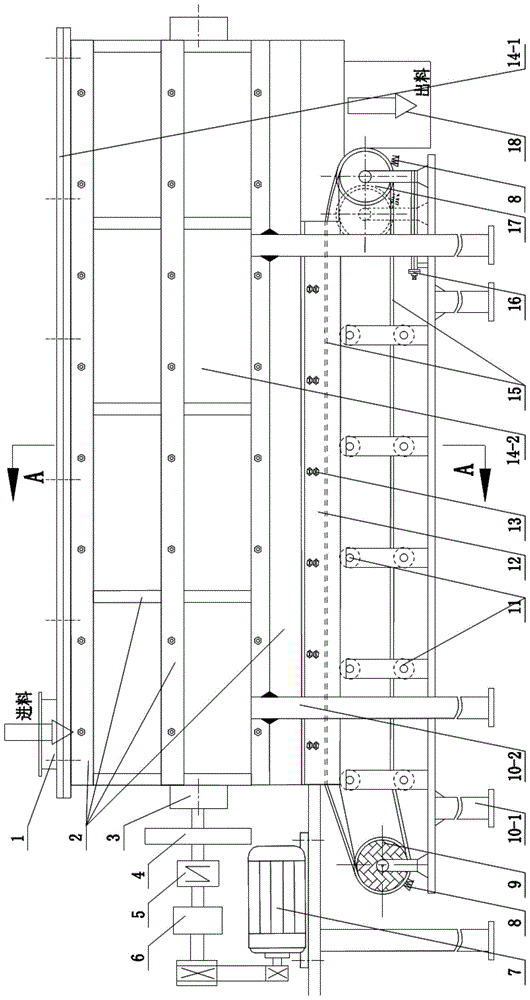

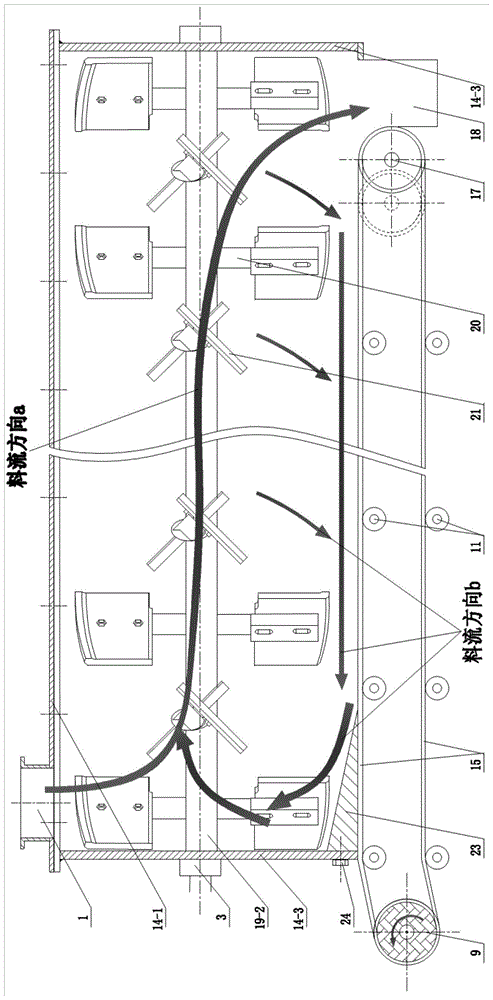

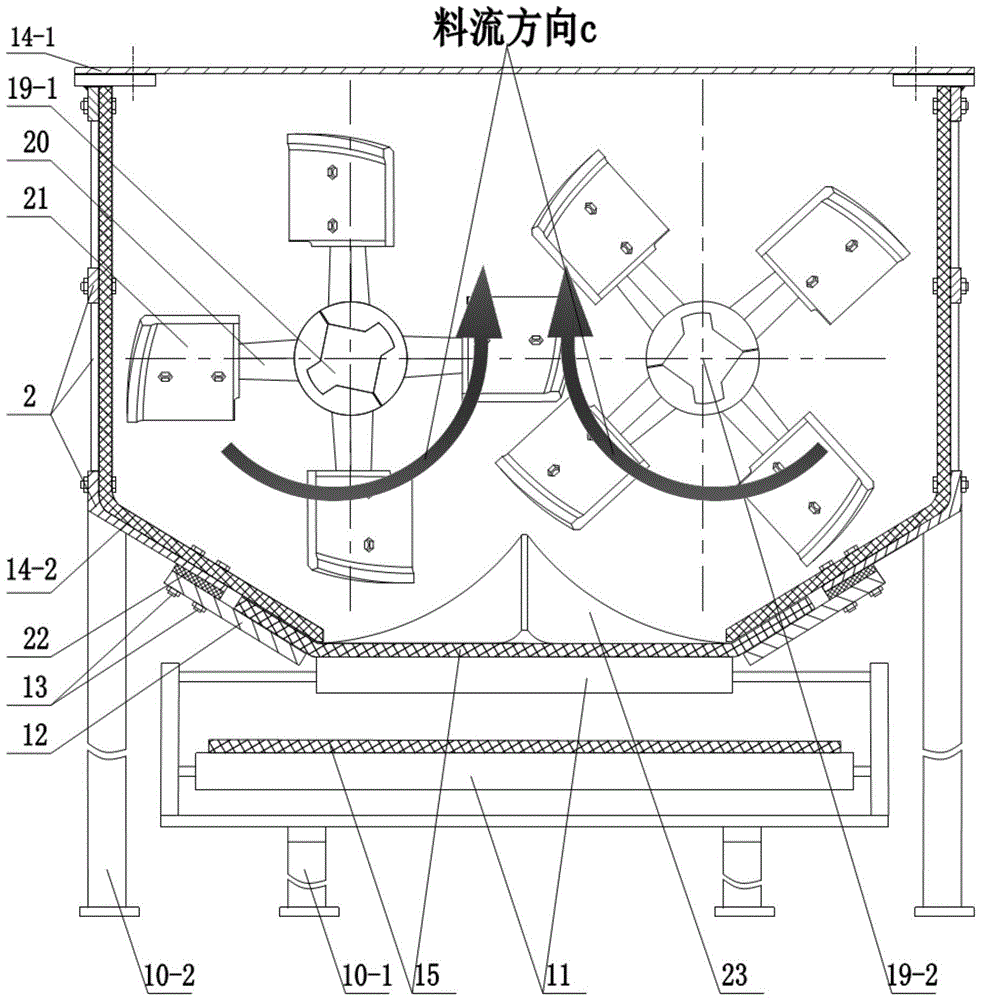

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0030] see Figure 1 to Figure 5 , a combined twin-shaft continuous mixer, including a mixing main structure and a conveyor belt structure, the main mixing structure includes a mixing drum, and the mixing drum includes a mixing drum upper cover 14-1, a mixing drum side plate 14-3 and several L-shaped The mixing drum lining plate 14-2, the front and back of the mixing drum are spliced by 4 L-shaped mixing drum lining plates 14-2, the end faces on both sides are the mixing drum side plates 14-3, and the top surface is the mixing drum liner plate 14-2. The upper cover of the drum 14-1; the outer side of the mixing drum is provided with a structural frame 2, the L-shaped mixing drum liner 14-2 is fixed on the structural frame 2 by bolts, and the side plate of the mixing drum 14-3 is connected to the structural frame 2 by welding On, the upper cover 14-1 of the mixing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com