Microporous resin thin film laminate and preparation method thereof

A technology of microporous resin and laminate, which is applied in the field of microporous resin film, composite and its bonding preparation, fabric and bonded laminate, which can solve the problem of only ventilation, hindering development, and easy to appear. Broken film and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

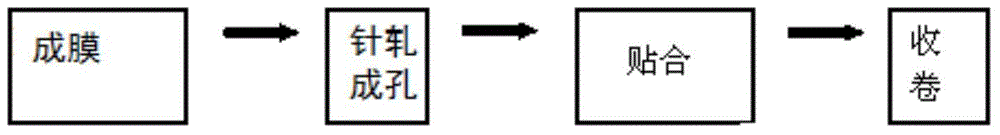

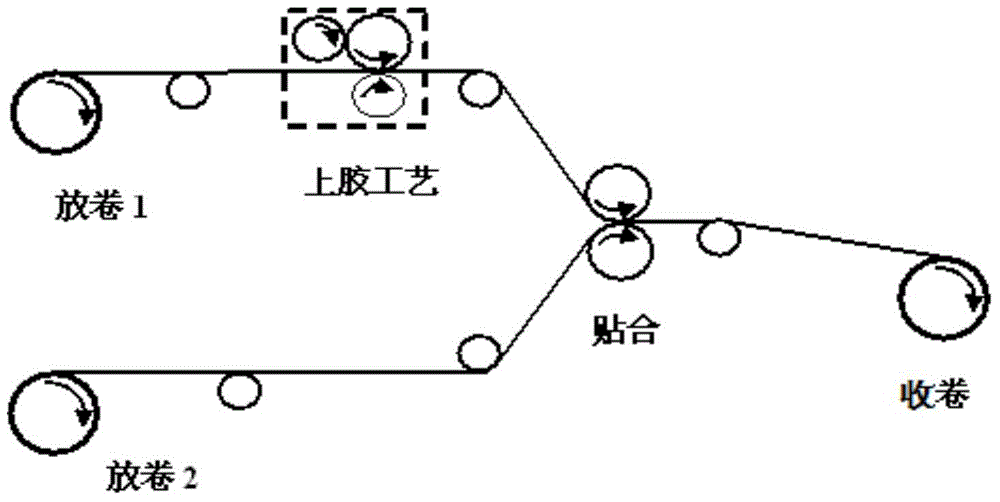

Method used

Image

Examples

Embodiment 1

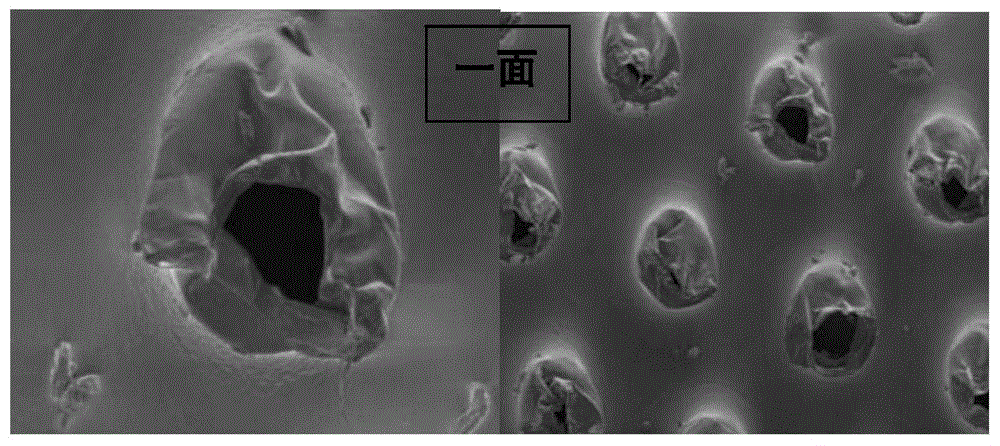

[0053] The 8μm convex surface hole diameter of 0.2mm polyester derivative needle-rolled microporous thermal film and 170g / m2 polyester four-way stretch knitted fabric are bonded to the point-shaped micro-concave plate with reactive hot-melt polyurethane glue, and the weight of the glue is 10g. / m2, production line speed 10m / min, cooling and winding. Carry out glue ripening again. Obtain a fabric with a smooth surface and no sticky touch. The softness ISO 17235 test result is 3.4, the peeling force GB8808 test result is 6.0N / 15cm, and the moisture permeability GB / T12704.1 test result is 3500g / m 2* 24h, the air permeability GB / T 5453 test result is 5-15mm / s, this example proves that the needle-rolled film plays the role of windproof and breathable, and also because of the existence of the hole, there is a difference in the internal and external humidity, glue penetration and pore blockage get relief.

Embodiment 2

[0055] The glue grammage of embodiment one is 15g / m , production line speed 10m / min, cooling winding. Carry out glue ripening again. Obtain a fabric with a smooth surface and no sticky touch. The softness ISO17235 test result is 3.6, the peeling force GB8808 test result is 8.0N / 15cm, and the moisture permeability GB / T 12704.1 test result is 3200g / m 2* After 24 hours, the air permeability GB / T 5453 test result is 5-15mm / s; this embodiment shows that the glue increases, and there is no glue seepage, and there is no large-scale clogging of the holes.

Embodiment 3

[0057] The production line speed of embodiment one is increased to 30m / min, cooling and winding. Carry out glue ripening again. A fabric with a smooth surface and no sticky touch was obtained. The softness ISO 17235 test result was 3.7, the peeling force GB88088 test result was 6.0N / 15cm, and the moisture permeability GB / T 12704.1 membrane surface test result was 3300g / m 2* 24 hours, the air permeability GB / T 5453 film surface test result is 5-15mm / s; the increase in production speed, the glue does not appear to leak when the glue is not completely cooled, and does not have too much impact on product performance.

[0058] Embodiment four, five, six

[0059] The convex surface of the 5, 10 μm, 12um polyester derivative needle-rolled microporous film and the polyester four-way stretch knitted fabric with a weight of 170g / m2 are laminated with a reactive hot-melt polyurethane adhesive for point-shaped micro-concave plates. Gram weight is 10g / m2, production line speed is 10m / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com