A kind of snowflake candle and preparation method thereof

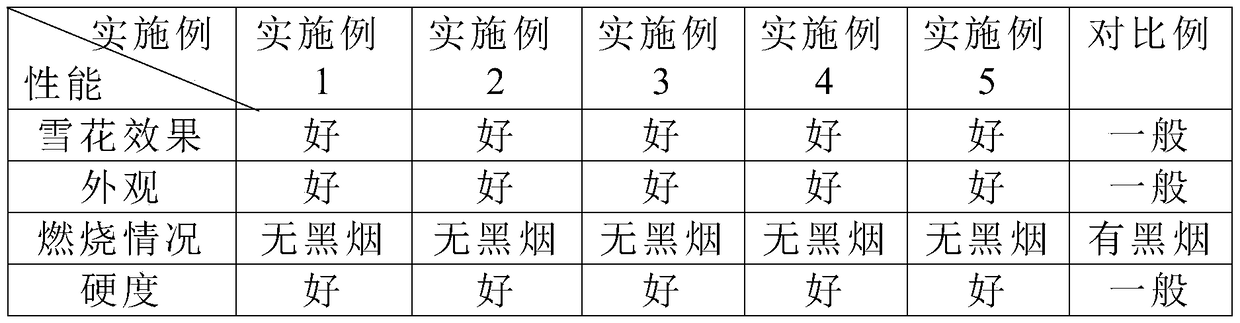

A technology for candles and snowflakes, applied in the field of snowflake candles and their preparation, can solve the problems of cumbersome processing technology of snowflake candles, and achieve the effects of improving snowflake effect, lasting color and fragrance, and improving overall hardness and heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

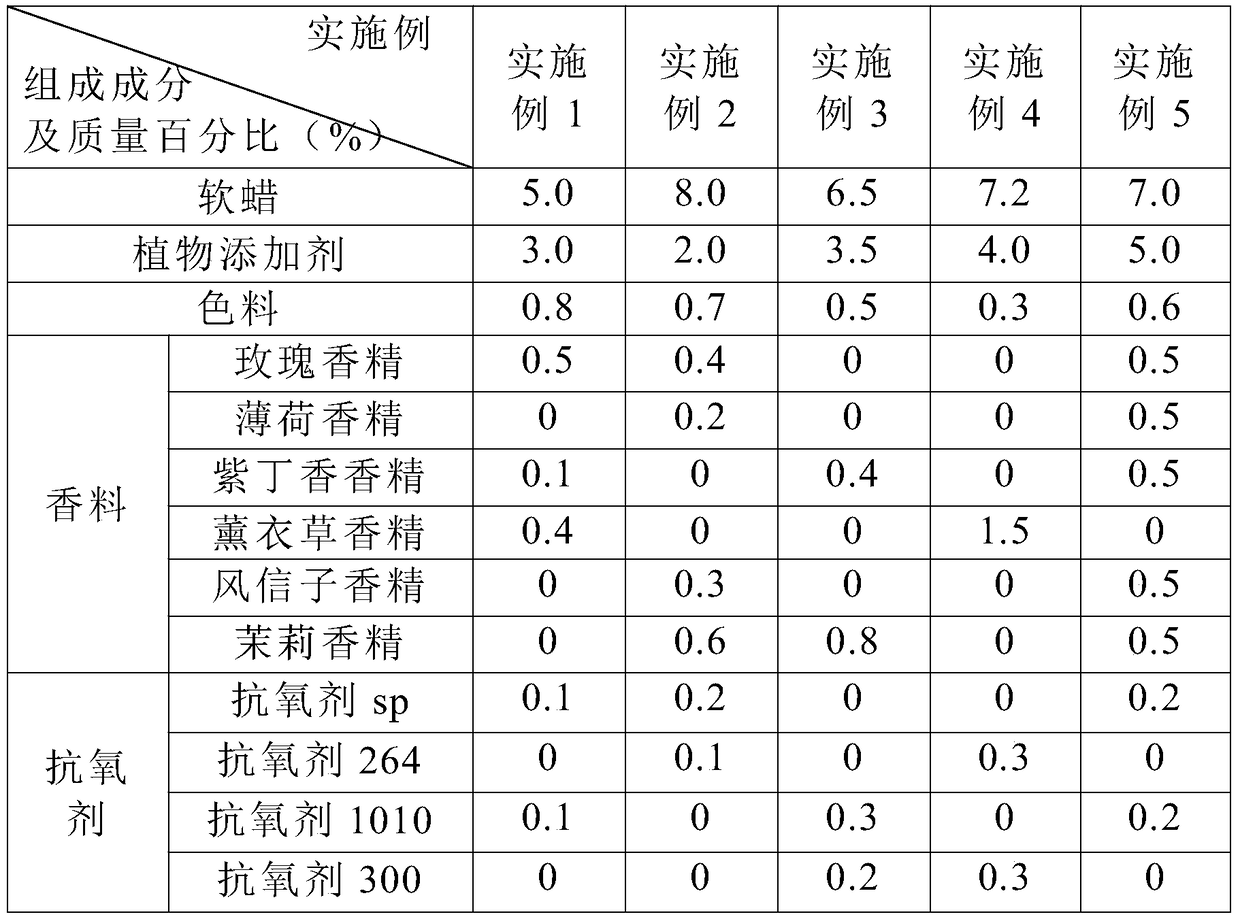

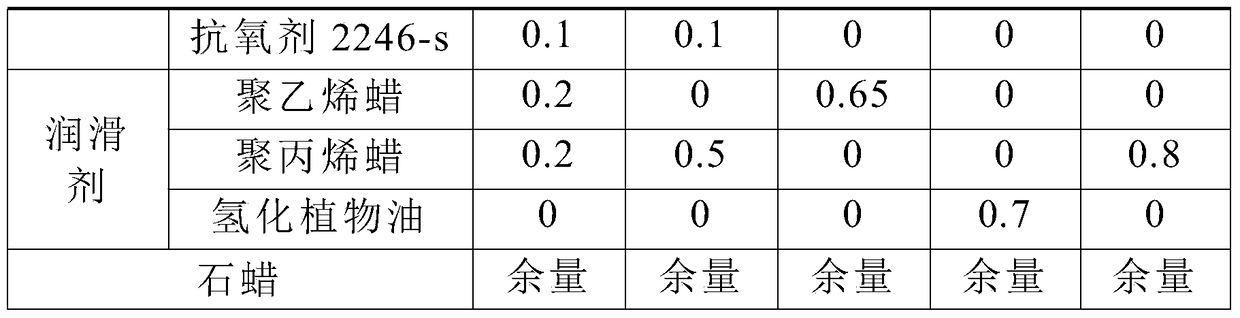

Examples

Embodiment 1

[0025] Mix the raw materials of the snowflake candle body described in Example 1 in Table 1 evenly, and then heat at 90° C. for 0.5 h to melt to obtain a wax liquid; wherein the mass ratio of carnauba wax:candelilla wax is 6:3.

[0026] Preheat the mold to 100°C, fix the pure cotton wick in the mold, pour the above-mentioned wax liquid, and then cool it at a constant temperature of 12°C to form it and then demould to obtain the finished snowflake candle; the mold is made of a plastic mold that resists fragrance corrosion , Keep the viscosity of the wax liquid at 0.4Pa.s during the pouring process, and the demoulding time is 1.2h.

Embodiment 2

[0028] Mix the raw materials of the snowflake candle body described in Example 2 in Table 1 evenly, then heat at 100°C for 1 hour, and melt to obtain a wax liquid; wherein the mass ratio of carnauba wax:candelilla wax is 5:3.

[0029] Preheat the mold to 105°C, fix the pure cotton wick in the mold, pour the above-mentioned wax liquid, and then cool it at a constant temperature of 12°C to form it and then demould to obtain the finished snowflake candle; the mold is made of a plastic mold that resists fragrance corrosion , Keep the viscosity of the wax liquid at 0.6Pa.s during the pouring process, and the demoulding time is 1.0h.

Embodiment 3

[0031] Mix the raw materials of the snowflake candle body described in Example 3 in Table 1 evenly, and then heat at 95°C for 0.8h to melt to obtain a wax liquid; wherein the mass ratio of carnauba wax:candelilla wax is 7:3.

[0032] Preheat the mold to 110°C, fix the pure cotton wick in the mold, pour the above-mentioned wax liquid, and then cool it at a constant temperature of 15°C to mold it and then demould to obtain the finished snowflake candle; the mold adopts a plastic mold that is anti-fragrance corrosion , Keep the viscosity of the wax liquid at 0.5Pa.s during the pouring process, and the demoulding time is 1.3h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com