Method for preparing TiAl-base alloy directional fully lamellar structure

A full-sheet, base alloy technology, applied in the field of material processing, can solve the problems of difficult seeding process, limited oriented full-sheet structure preparation and application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

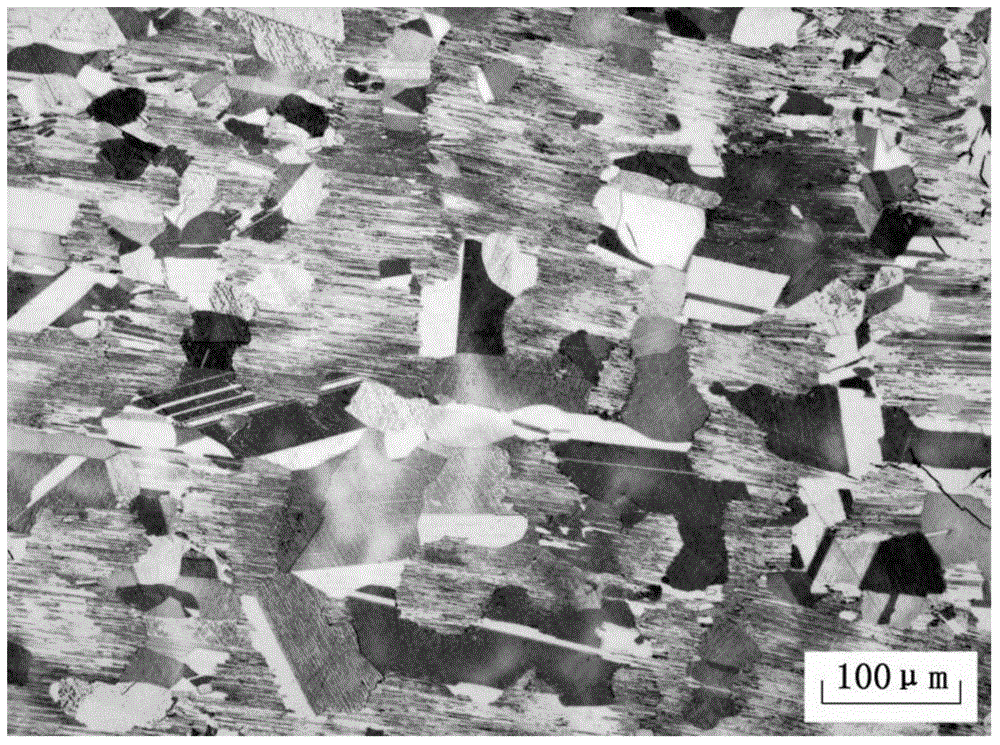

[0030] This embodiment is a method to keep the lamellar structure in the Ti-48Al-2Nb-2Cr alloy quasi-seed crystal stable by rapid heating, thereby controlling the lamellar direction in the directional solidification, and finally obtaining the directional full Method of lamellar organization.

[0031] The first step, sample preparation: Prepare a sample with a composition of Ti-48Al-2Nb-2Cr and a size of Φ30mm×70mm as a quasi-seed crystal alloy, and the lamellar direction in the quasi-seed crystal alloy is parallel to the axial direction of the sample . A sample whose composition is Ti-48Al-2Nb-2Cr and whose size is Φ30mm×200mm is prepared as the base metal alloy.

[0032] The second step is to install the sample: install the prepared quasi-seed crystal on the pull rod of the electromagnetic constrained forming directional solidification device. Install the base metal on the feeding rod of the electromagnetic constrained forming directional solidification device, and at the s...

Embodiment 2

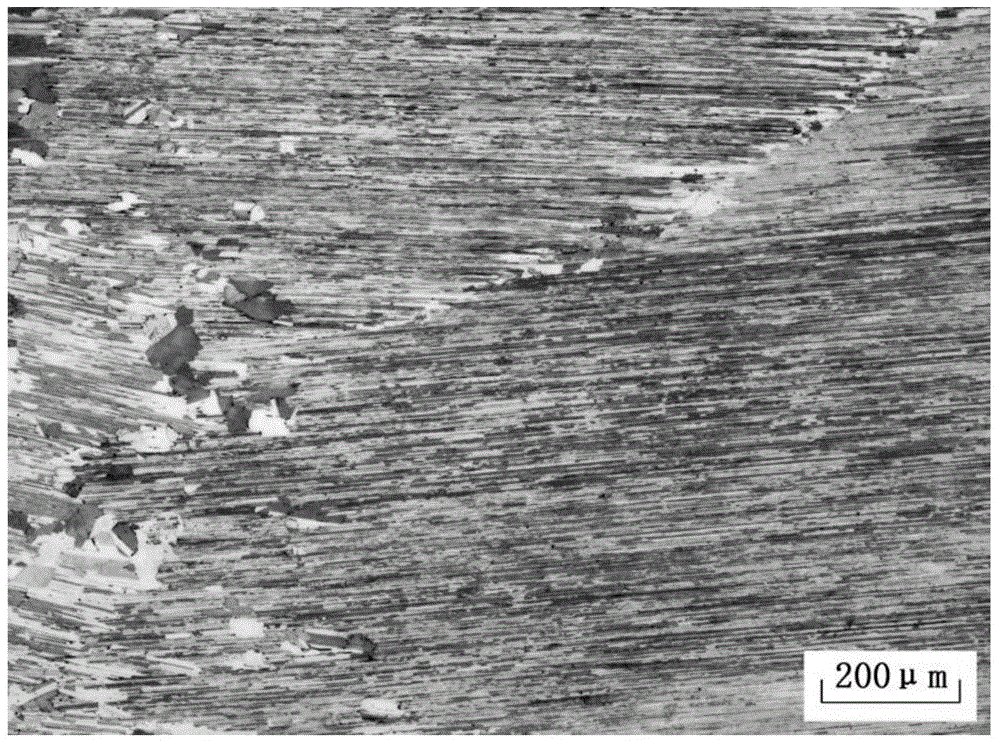

[0037] This embodiment is a method to keep the lamellar structure in the Ti-48Al-6Nb-1Cr alloy quasi-seed crystal stable by rapid heating, so as to control the lamellar direction in the directional solidification, and finally obtain the directional completeness parallel to the pulling direction. Method of lamellar organization.

[0038] The first step, sample preparation: Prepare a sample with a composition of Ti-48Al-6Nb-1Cr and a size of Φ10mm×70mm as a quasi-seed crystal alloy, and the lamellar direction in the quasi-seed crystal is parallel to the sample axis. A sample with a composition of Ti-48Al-6Nb-1Cr and a size of Φ10mm×200mm was prepared as the base metal alloy.

[0039] The second step is to install the sample: install the prepared quasi-seed crystal on the pulling rod of the electromagnetic constrained forming directional solidification device, and ensure that the lamellar direction of the quasi-seed crystal is parallel to the pulling direction during directional ...

Embodiment 3

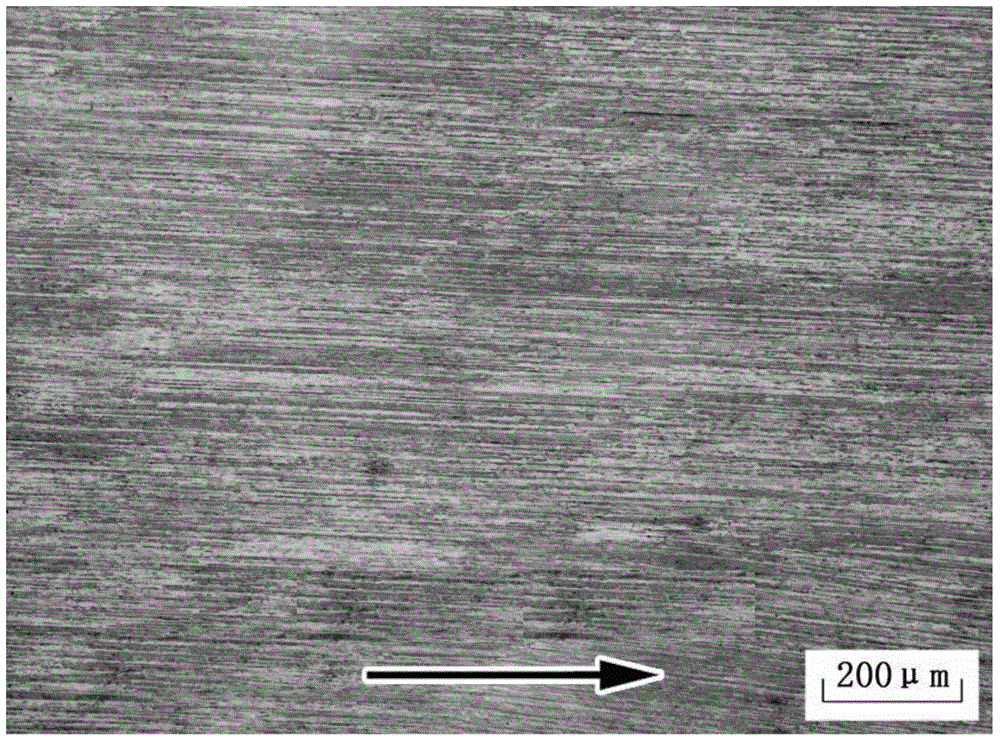

[0044] This embodiment is a method to keep the lamellar structure in the Ti-48Al-2Nb-2Cr alloy quasi-seed crystal stable by rapid heating, thereby controlling the lamellar direction in the directional solidification, and finally obtaining the directional full Method of lamellar organization.

[0045] The first step, sample preparation: Prepare a sample with a composition of Ti-48Al-2Nb-2Cr and a size of Φ25mm×70mm as a quasi-seed crystal alloy, and the lamellar direction in the quasi-seed crystal is parallel to the sample axis. A sample whose composition is Ti-48Al-2Nb-2Cr and whose size is Φ25mm×200mm is prepared as the base metal alloy.

[0046] The second step is to install the sample: install the prepared quasi-seed crystal on the pulling rod of the electromagnetic constrained forming directional solidification device, and ensure that the lamellar direction of the quasi-seed crystal is parallel to the pulling direction during directional solidification. Install the base m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com