Construction method for pouring water-stopping upstanding beams in kitchens and toilets

A construction method and kitchen and bathroom technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of water seepage at the joint between the water-stop anti-beam and the original concrete, affecting the construction quality of the project, and increasing the construction cost. Achieve the effect of solving the problem of water leakage at the root, shortening the construction period, and making the construction sequence reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

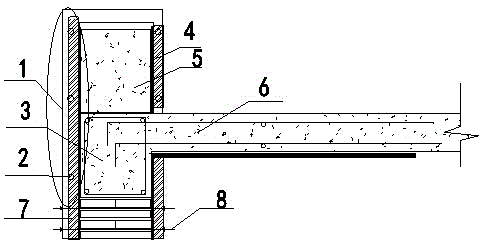

[0023] Below in conjunction with accompanying drawing, construction method of the present invention is described in further detail.

[0024] A construction method for pouring water-stop anti-beams in kitchen and bathroom, characterized in that it includes the following steps:

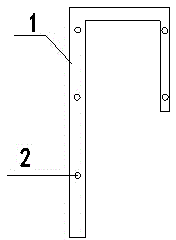

[0025] Step 1: Make hanging mold support 1;

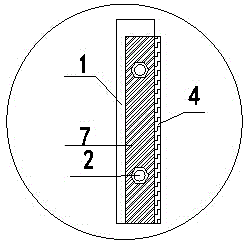

[0026] The hanger bracket 1 is a "n" shape structure, and the two sides of the hanger bracket 1 are provided with connecting holes 2; the hanger bracket 1 is made of 5# channel steel;

[0027] Step 2: Set up the template;

[0028] The bottom of the hanging formwork bracket 1 is fixedly connected to the body of wall through the pull bolts 8, the two sides of the hanging formwork support 1 are fixedly connected with the square wood 7 by bolts, and then the formwork 4 is fixed on the hanging formwork support 1; the hanging formwork The lower part of the support 1 is provided with a ring beam 3, and the steel bars of the ring beam 3 and the floor 6 are bound a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com