A car cylinder liner

A technology for cylinder liner and car, applied in the direction of cylinder, cylinder head, engine components, etc., can solve the problems of deformation, uneven cylinder hole, can not meet the engine heat dissipation, etc., to reduce the cylinder center distance, solve the cylinder hole deformation, improve the combination rate and bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

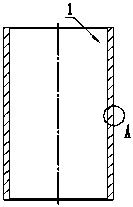

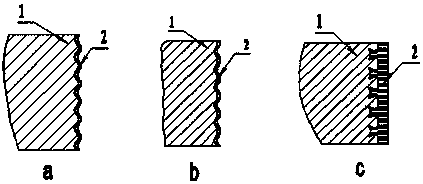

[0020] like figure 1 and figure 2 As shown in a, a cylinder liner for a car comprises a cylinder liner substrate 1 and a spray coating 2 sprayed on the outer peripheral surface of the substrate; the outer peripheral surface of the substrate 1 is a helical texture, and the crests of the helical texture are in the form of A straight line perpendicular to the radial direction of the cylinder liner base.

[0021] The preparation method of above-mentioned car cylinder liner, it comprises the steps:

[0022] 1) The base body of the cylinder liner is cut by a lathe to make the outer circumferential surface a spiral pattern;

[0023] 2) Roughen the outer peripheral surface of the cylinder liner substrate, and the roughness Rz of the outer peripheral surface of the cylinder liner substrate after treatment is above 50 μm; the outer peripheral surface is purified; the material used for the roughening treatment is 24-mesh white corundum. Specifically, it may be: using compressed air w...

Embodiment 2

[0027] like figure 1 and figure 2 As shown in b, a cylinder liner for a car, which includes a cylinder liner substrate 1 and a spray coating 2 sprayed on the outer peripheral surface of the substrate; the outer peripheral surface of the substrate 1 is a spiral pattern, and the crest of the spiral pattern is Arc shape perpendicular to the radial direction of the cylinder liner base.

[0028] The preparation method of above-mentioned car cylinder liner, it comprises the steps:

[0029] 1) The base body of the cylinder liner is cut by a lathe to make the outer circumferential surface a spiral pattern;

[0030] 2) Roughen the outer peripheral surface of the cylinder liner substrate, the roughness Rz of the outer peripheral surface of the cylinder liner substrate after treatment is above 60 μm; the outer peripheral surface is purified; the materials used for the roughening treatment are 16 mesh and 24 mesh Mix white corundum. Specifically, it may be: use compressed air with a ...

Embodiment 3

[0034] like figure 1 and figure 2 As shown in c, a cylinder liner for a car comprises a cylinder liner substrate 1 and a spray coating 2 sprayed on the outer peripheral surface of the substrate; the outer peripheral surface of the substrate 1 is a helical texture, and the longitudinal section of the helical texture is composed of It is composed of several dovetail grooves arranged in parallel.

[0035] The preparation method of above-mentioned car cylinder liner, it comprises the steps:

[0036] 1) The base body of the cylinder liner is cut by a lathe to make the outer circumferential surface a spiral pattern;

[0037] 2) Roughen the outer peripheral surface of the cylinder liner substrate, the roughness Rz of the outer peripheral surface of the cylinder liner substrate after treatment is above 40 μm; the outer peripheral surface is purified; the material used for the roughening treatment is steel with a particle size of G17 sand. Specifically, it may be: using compressed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com