A double-suction centrifugal fan

A centrifugal fan, double-suction technology, used in mechanical equipment, non-variable-capacity pumps, machines/engines, etc., can solve the problems of complicated internal flow conditions and reduced fan performance in centrifugal fans, and achieve improved static pressure- Effect of flow characteristics, improved aerodynamic performance, enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

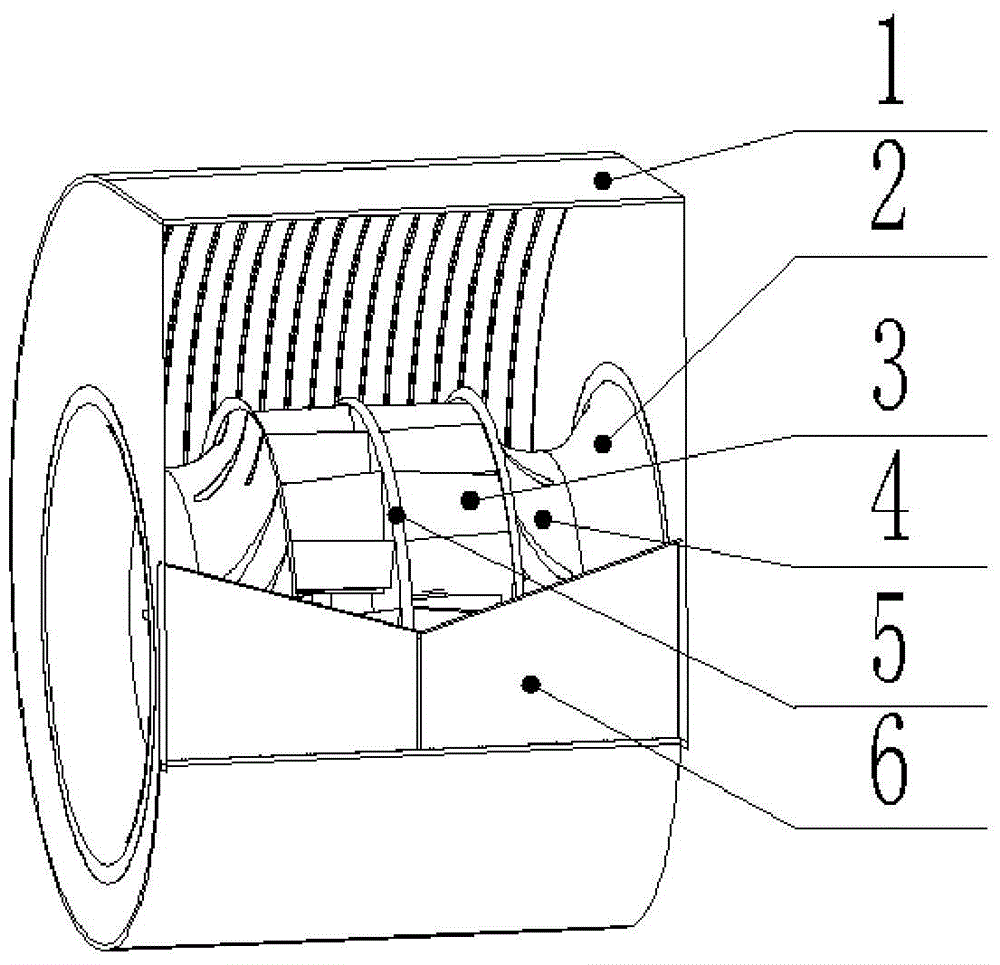

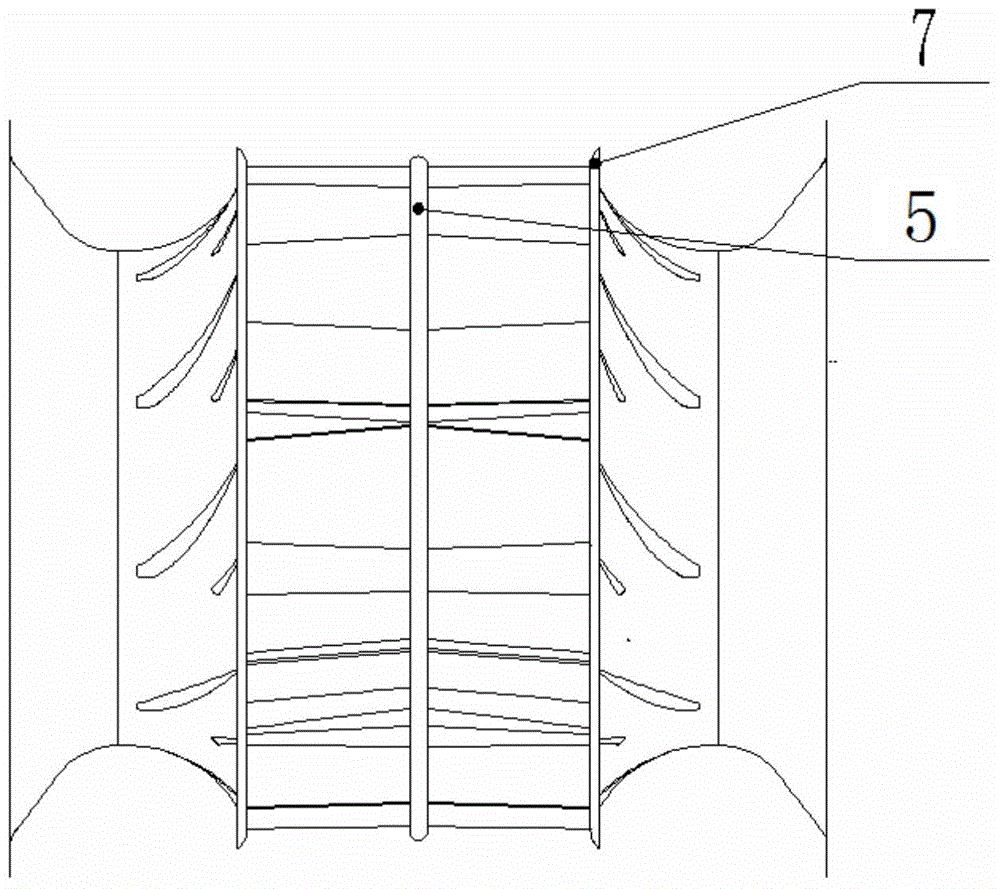

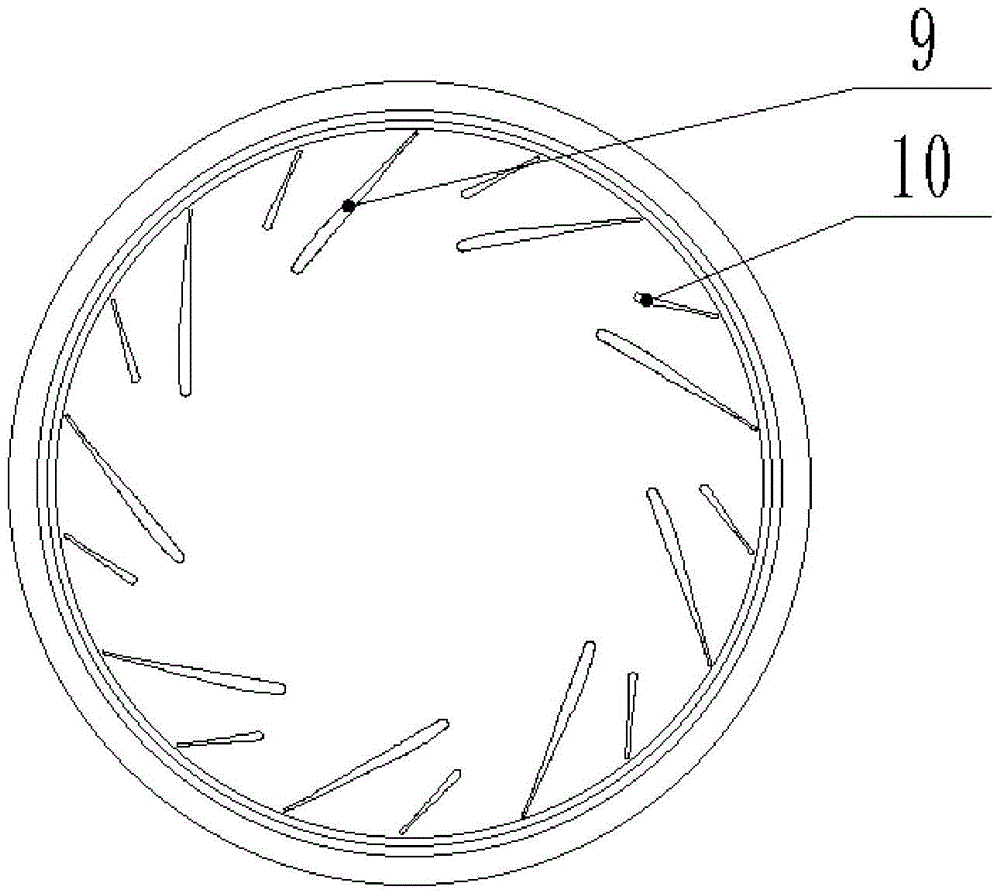

[0018] Such as figure 1 , 2 Shown in and 3, a double-suction centrifugal fan includes a volute 1, a front guide 2 and a double-suction impeller 3; the volute 1 is provided with a baffle 6 at the outlet; the double-suction impeller 3 includes a wheel cover 4. Wheel disc 5 and blade group; two blade groups are arranged symmetrically on both sides of the wheel disc 5; the blade group includes long blades 9 and short blades 10; nine long blades 9 are evenly distributed along the circumference, and two adjacent long blades 9 are provided with short blades 10; all short blades 10 are evenly distributed along the circumference; end welding; the outer ends of the two wheel covers 4 are welded with a front guide 2 respectively.

[0019] The edge of the welding end of wheel cover 4, long blade 9 and short blade 10 is provided with a bladeless diffuser edge 7; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com