Automatic water and oil discharging device for ammonia refrigeration system

A technology of automatic drainage and oil drainage device, which is used in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problem of manual drainage and oil drainage of ammonia refrigeration system, so as to improve the cooling effect, reduce energy consumption and high drainage efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

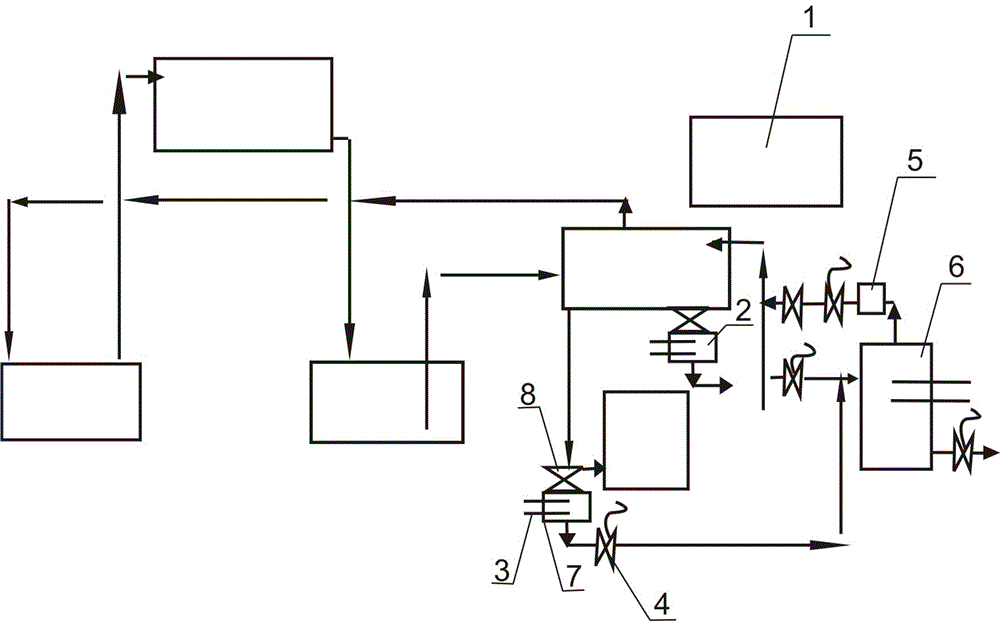

[0014] Such as figure 1 As shown, an automatic drainage and oil discharge device for ammonia refrigeration system, the device includes: PLC controller 1 passes through water concentration detector 2, electric heating tube 3, sewage solenoid valve 4 and ammonia compressor 5 respectively The signal line is connected, the oil and water collection separator 7 with ammonia stop valve 8 is installed at the lowest point of the ammonia refrigeration system, the electric heating pipe 3 is fixedly connected to the oil and water collection separator 7, and the water concentration detector 2 is connected to the ammonia stop valve 8 are fixedly connected.

[0015] The function of the water concentration detector 2 is to monitor the water concentration, so as to provide a basis for the actions of oil discharge and drainage; the function of the sewage discharge solenoid valve 4 is to perform the actions of oil discharge and drainage.

[0016] The oil and water collection separator 7 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com