Industrial waste steam condensing device

A condensing device and waste steam technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of breeding harmful bacteria, changing atmospheric pressure, heat waste, etc., to speed up the condensation speed, increase the contact area, avoid The effect of re-vaporization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

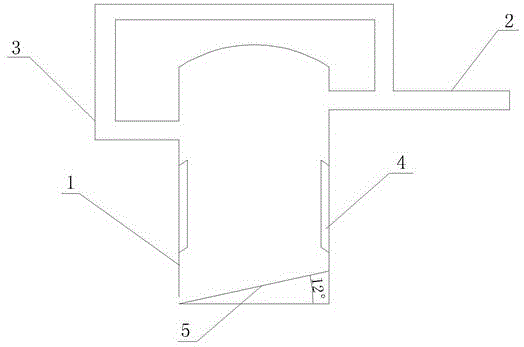

[0013] Example 1, such as figure 1 As shown, a waste steam condensing device provided in this embodiment includes a condensation chamber 1, a waste steam inlet pipe 2, a waste steam recovery pipe 3 and a water collection area 5, and a waste steam inlet pipe is connected to the inner wall of the condensation chamber 1 2. The inlet of the waste steam inlet pipe 2 collects the waste steam generated during the industrial operation. In contrast, the waste steam recovery pipe 3 is provided on the inner wall of the condensation chamber 1, the output port of the waste steam recovery pipe 3 communicates with the inlet of the waste steam inlet pipe 2, and the position of the waste steam recovery pipe 3 is lower than that of the waste steam The position of the inlet pipe 2 is favorable for the waste steam to be fully condensed in the condensation chamber 1 .

[0014] The water collection area 5 is located at the bottom of the condensation chamber 1, and the bottom of the water collectio...

Embodiment 2

[0015] Embodiment 2. The difference between this embodiment and Embodiment 1 is that the inside of the condensate 4 communicates with an external condensing device, and the condensing device cools the air in the condensate 4 to cool the waste steam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com